EN 415-6:2006

(Main)Safety of packaging machines - Part 6: Pallet wrapping machines

Safety of packaging machines - Part 6: Pallet wrapping machines

This standard applies to the following groups of machines:

- pallet banding machines;

- stretch film pallet wrapping machines;

- stretch film hood application machines;

- mobile stretch film wrapping machines;

- semi automatic self driving stretch film wrapping machines;

- shrink film pallet wrapping machines;

- shrink film hood application machines;

- film removing machines;

- shrinking systems;

- sleeve wrapping machines for product greater than 400 mm in one direction;

- product centralising machines.

The individual machines are described in 3.2.

This standard deals with safety requirements for machine design, construction, installation, commissioning, operation, adjustment, maintenance and cleaning of pallet wrapping machines.

The extents to which hazards, hazardous situations and events are covered are indicated in Clause 4.

Exclusions

This standard is not applicable to the following machines:

- machines that were manufactured before the date of publication of this document by CEN;

- pallet strapping machines and destrapping machines. These machines are within the scope of prEN 415-8

- conveying systems that connect packaging machines with each other, but includes conveying systems that are part of the machines;

This standard does not consider the following hazards:

- the use of pallet wrapping machines in potentially explosive atmospheres;

- the health, safety or hygiene hazards associated with the products that may be handled by the machines, but does include general advice on this subject;

- hazards that may be associated with electromagnetic emissions from pallet wrapping machines;

- hazards that may be associated with decommissioning pallet wrapping machines.

Sicherheit von Verpackungsmaschinen - Teil 6: Paletteneinschlagmaschinen

Diese Norm behandelt folgende Maschinengruppen:

Palettenbanderoliermaschinen;

Palettenstretchfolieneinschlagmaschinen;

Stretchfolienhaubenüberziehmaschinen;

fahrbare Palettenstretchfolieneinschlagmaschinen;

halbautomatische selbstfahrende Palettenstretchfolieneinschlagmaschinen;

Palettenschrumpffolieneinschlagmaschinen;

Schrumpffolienhaubenüberziehmaschinen;

Folienabziehmaschinen;

Schrumpfsysteme;

Schrumpffolieneinschlagmaschinen für Produkte mit einer Größe von mehr als 400 mm in einer Richtung;

Ladungszentriermaschinen.

Die einzelnen Maschinenarten werden in 3.2 beschrieben.

Diese Norm beschreibt Sicherheitsanforderungen für Konstruktion, Bau, Installation, Inbetriebnahme, Betrieb, Einstellung, Instandhaltung und Reinigung von Paletteneinschlagmaschinen.

Der Umfang der behandelten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse ist in Abschnitt 4 angegeben.

Ausnahmen

Diese Norm ist nicht anwendbar auf folgende Maschinen:

Maschinen, die vor der Veröffentlichung dieses Dokuments durch CEN hergestellt wurden;

PalettenuUmreifungsmaschinen- und -entreifungsmaschinen. Diese Maschinen liegen im Geltungsbereich von prEN 415-8;

Maschinen zum Entfernen der Umreifung;

Förderanlagen, die Verpackungsmaschinen miteinander verbinden; eingeschlossen sind jedoch in die Maschine integrierte Förderanlagen.

Diese Norm berücksichtigt folgende Gefährdungen nicht:

den Einsatz von Paletteneinschlagmaschinen in explosionsgefährdeten Atmosphären;

Gefährdungen für Gesundheit, Sicherheit oder Hygiene, die sich durch die Produkte ergeben, die von den Maschinen verarbeitet werden. Jedoch werden allgemeine Hinweise zu diesem Thema gegeben;

Gefährdungen durch elektromagnetische Emissionen von Paletteneinschlagmaschinen;

Gefährdungen, die sich bei der Außerbetriebnahme von Paletteneinschlagmaschinen ergeben können.

Sécurité des machines d'emballage - Partie 6 : Machines d'emballage de palettes

La présente norme s’applique aux groupes de machines suivants :

les banderoleuses de palettes ;

les fardeleuses de palettes par film étirable ;

les housseuses à film étirable ;

les fardeleuses mobiles à film étirable ;

les fardeleuses automotrices semi automatiques à film étirable ;

les fardeleuses de palettes par film rétractable ;

les housseuses à tube rétractable ;

les ôteurs de films ;

les systèmes de rétreint ;

les banderoleuses par film rétractable pour produits mesurant plus de 400 mm dans la même direction ;

les machines à centrer les produits.

Chaque machine est décrite en 3.2.

La présente Norme traite des exigences de sécurité en matière de conception, de construction, d’installation, de mise en service, de fonctionnement, de réglage, de maintenance et de nettoyage des machines d’emballage de palettes.

L’étendue des phénomènes dangereux, situations et événements dangereux couverts est indiquée à l’Article 4 du présent document.

Exclusions

La présente norme ne s’applique pas aux machines suivantes :

les machines qui ont été fabriquées avant la date de publication du présent document par le CEN ;

les cercleuses et les décercleuses ; ces machines sont dans le domaine d’application du prEN 415-8 ;

les dispositifs de convoyage qui relient les machines d’emballage entre elles, à l’exception des dispositifs de convoyage intégrés aux machines.

La présente Norme ne traite pas des phénomènes dangereux suivants :

l’utilisation des machines d’emballage de palettes dans les atmosphères explosibles ;

les risques pour la santé, la sécurité ou l’hygiène liés aux produits éventuellement utilisés pour les machines, tout en comportant néanmoins des conseils d’ordre général sur le sujet ;

les risques pouvant être liés aux émissions électromagnétiques des machines d’emballage de palettes ;

les risques pouvant être liés au démantèlement des machines d’emballage de palettes

Pakirne naprave – Varnost pakirnih naprav – 6. del: Zavijalni stroji

General Information

- Status

- Withdrawn

- Publication Date

- 12-Dec-2006

- Withdrawal Date

- 13-Oct-2009

- Technical Committee

- CEN/TC 146 - Packaging machines - Safety

- Drafting Committee

- CEN/TC 146/WG 6 - Unit load securing machines

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 14-Oct-2009

- Completion Date

- 14-Oct-2009

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BRCGS

Global food safety and quality certification programme owner.

Sponsored listings

Frequently Asked Questions

EN 415-6:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of packaging machines - Part 6: Pallet wrapping machines". This standard covers: This standard applies to the following groups of machines: - pallet banding machines; - stretch film pallet wrapping machines; - stretch film hood application machines; - mobile stretch film wrapping machines; - semi automatic self driving stretch film wrapping machines; - shrink film pallet wrapping machines; - shrink film hood application machines; - film removing machines; - shrinking systems; - sleeve wrapping machines for product greater than 400 mm in one direction; - product centralising machines. The individual machines are described in 3.2. This standard deals with safety requirements for machine design, construction, installation, commissioning, operation, adjustment, maintenance and cleaning of pallet wrapping machines. The extents to which hazards, hazardous situations and events are covered are indicated in Clause 4. Exclusions This standard is not applicable to the following machines: - machines that were manufactured before the date of publication of this document by CEN; - pallet strapping machines and destrapping machines. These machines are within the scope of prEN 415-8 - conveying systems that connect packaging machines with each other, but includes conveying systems that are part of the machines; This standard does not consider the following hazards: - the use of pallet wrapping machines in potentially explosive atmospheres; - the health, safety or hygiene hazards associated with the products that may be handled by the machines, but does include general advice on this subject; - hazards that may be associated with electromagnetic emissions from pallet wrapping machines; - hazards that may be associated with decommissioning pallet wrapping machines.

This standard applies to the following groups of machines: - pallet banding machines; - stretch film pallet wrapping machines; - stretch film hood application machines; - mobile stretch film wrapping machines; - semi automatic self driving stretch film wrapping machines; - shrink film pallet wrapping machines; - shrink film hood application machines; - film removing machines; - shrinking systems; - sleeve wrapping machines for product greater than 400 mm in one direction; - product centralising machines. The individual machines are described in 3.2. This standard deals with safety requirements for machine design, construction, installation, commissioning, operation, adjustment, maintenance and cleaning of pallet wrapping machines. The extents to which hazards, hazardous situations and events are covered are indicated in Clause 4. Exclusions This standard is not applicable to the following machines: - machines that were manufactured before the date of publication of this document by CEN; - pallet strapping machines and destrapping machines. These machines are within the scope of prEN 415-8 - conveying systems that connect packaging machines with each other, but includes conveying systems that are part of the machines; This standard does not consider the following hazards: - the use of pallet wrapping machines in potentially explosive atmospheres; - the health, safety or hygiene hazards associated with the products that may be handled by the machines, but does include general advice on this subject; - hazards that may be associated with electromagnetic emissions from pallet wrapping machines; - hazards that may be associated with decommissioning pallet wrapping machines.

EN 415-6:2006 is classified under the following ICS (International Classification for Standards) categories: 55.200 - Packaging machinery. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 415-6:2006 has the following relationships with other standards: It is inter standard links to EN 415-6:2006+A1:2009, EN 415-1:2000+A1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 415-6:2006 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/079. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 415-6:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Safety of packaging machines - Part 6: Pallet wrapping machinesPakirne naprave – Varnost pakirnih naprav – 6. del: Zavijalni strojiSécurité des machines d'emballage - Partie 6 : Machines d'emballage de palettesSicherheit von Verpackungsmaschinen - Teil 6: PaletteneinschlagmaschinenTa slovenski standard je istoveten z:EN 415-6:2006SIST EN 415-6:2007en55.200Pakirni strojiPackaging machineryICS:SLOVENSKI

STANDARDSIST EN 415-6:200701-marec-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 415-6December 2006ICS 55.200 English VersionSafety of packaging machines - Part 6: Pallet wrappingmachinesSécurité des machines d'emballage - Partie 6 : Machinesd'emballage de palettesSicherheit von Verpackungsmaschinen - Teil 6:PaletteneinschlagmaschinenThis European Standard was approved by CEN on 4 September 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 415-6:2006: E

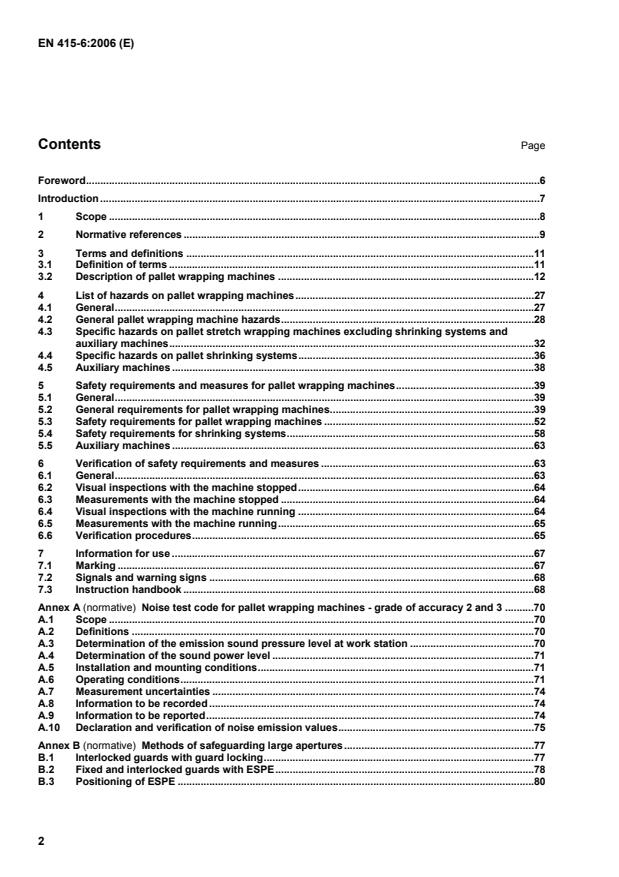

Noise test code for pallet wrapping machines - grade of accuracy 2 and 3.70 A.1 Scope.70 A.2 Definitions.70 A.3 Determination of the emission sound pressure level at work station.70 A.4 Determination of the sound power level.71 A.5 Installation and mounting conditions.71 A.6 Operating conditions.71 A.7 Measurement uncertainties.74 A.8 Information to be recorded.74 A.9 Information to be reported.74 A.10 Declaration and verification of noise emission values.75 Annex B (normative)

Methods of safeguarding large apertures.77 B.1 Interlocked guards with guard locking.77 B.2 Fixed and interlocked guards with ESPE.78 B.3 Positioning of ESPE.80

ESPE-Muting.82 Annex D (informative)

List of possibly helpful standards for gas equipment.84 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.85 Bibliography.86

When provisions of this type C standard are different from those, which are stated in type A or B standards, the provisions of this type C standard take precedence.

1 Scope This standard applies to the following groups of machines: pallet banding machines; stretch film pallet wrapping machines; stretch film hood application machines; mobile stretch film wrapping machines; semi automatic self driving stretch film wrapping machines; shrink film pallet wrapping machines; shrink film hood application machines; film removing machines; shrinking systems; sleeve wrapping machines for product greater than 400 mm in one direction; product centralising machines. The individual machines are described in 3.2.

This standard deals with safety requirements for machine design, construction, installation, commissioning, operation, adjustment, maintenance and cleaning of pallet wrapping machines. The extents to which hazards, hazardous situations and events are covered are indicated in Clause 4. Exclusions This standard is not applicable to the following machines: machines that were manufactured before the date of publication of this document by CEN; pallet strapping machines and destrapping machines. These machines are within the scope of prEN 415-8 conveying systems that connect packaging machines with each other, but includes conveying systems that are part of the machines; This standard does not consider the following hazards: the use of pallet wrapping machines in potentially explosive atmospheres; the health, safety or hygiene hazards associated with the products that may be handled by the machines, but does include general advice on this subject; hazards that may be associated with electromagnetic emissions from pallet wrapping machines;

hazards that may be associated with decommissioning pallet wrapping machines.

EN 60529, Degrees of protection provided by enclosures (IP code) (IEC 60529:1989) EN 61310-1:1995, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for visual, auditory and tactile signals (IEC 61310-1:1995) EN 61310-3, Safety of machinery — Indication, marking and actuation — Part 3: Requirements for the location and operation of actuators (IEC 61310-3:1999) EN 61496-1:2004, Safety of machinery — Electro-sensitive protective equipment — Part 1: General requirements and tests (IEC 61496-1:2004, modified) EN 61508-1, Functional safety of electrical/electronic/programmable electronic safety-related systems — Part 1: General requirements (IEC 61508-1:1998 + Corrigendum 1999) EN 61508-2, Functional safety of electrical/electronic/programmable electronic safety-related systems — Part 2: Requirements for electrical/electronic/programmable electronic safety-related systems (IEC 61508-2:2000) EN 61508-3, Functional safety of electrical/electronic/programmable electronic safety-related systems — Part 3: Software requirements

EN 62061:2005, Safety of machinery — Functional safety of safety-related electrical, electronic and programmable electronic control systems EN ISO 3744:1995, Acoustics — Determination of sound power levels of noise sources using sound pressure — Engineering method in an essentially free field over a reflecting plane (ISO 3744:1994) EN ISO 3746:1995, Acoustics — Determination of sound power levels of noise sources using sound pressure — Survey method using an enveloping measurement surface over a reflecting plane (ISO 3746:1995) EN ISO 3747:2000, Acoustics — Determination of sound power levels of noise sources using sound pressure — Comparison method for use in situ (ISO 3747:2000) EN ISO 4871:1996, Acoustics — Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996)

3.1 Definition of terms 3.1.1 product article or articles, with or without pallet, that are handled in the pallet wrapping machine 3.1.2 pack assembly of product and packaging materials produced by a pallet wrapping machine

3.2.2 Spiral stretch wrapping machines 3.2.2.1 General The stretching method uses film webs that are wound around product according to a given winding pattern (e. g. single or cross bracing). The number of the bottom windings or bottom edge windings or the degree of overlapping of the film webs can be variably adjusted.

Optional assemblies: conveyors, film clamp, film knife, film sealing device, hold-down plate, pre-stretching unit on the film reel assembly, top sheet feeder.

Figure 1 — Principle of rotary table machine Figure 2 — Manual rotary table machine

Key 1 hold down plate

2 pre-stretching device

3 film reel

4 film fixture system

5 conveyor 6 rotary table

7 film cutting device Figure 3 — Automatic rotary table machine 3.2.2.3 Rotary arm machine Machine which wraps product in film or net, from a reel on an arm which rotates around the stationary product (see Figure 4 and Figure 5 The principle components are: rotating arm, film reel assembly and lifting mechanism which moves the arm up and down. Optional assemblies: conveyors, film clamp, film knife, film sealing device, hold-down plate, pre-stretching unit on the film reel assembly, top sheet feeder.

Key 1 rotary arm

2 product

3 film

4 conveying device Figure 4 — Semiautomatic rotary arm machine

Key 1 vertical slide device

2 pre-stretching device

3 film reel assembly

4 film fixture system

5 conveying device

6 rotary arm

7 top sheet feeder Figure 5 — Fully automatic rotary arm machine

3.2.2.4 Ring machine In a ring machine a film carriage guided on a ring moves circularly around the stationary product (see Figure 6). Some examples have a tilting ring to apply a diagonal wrap. The principle components are: rotating mechanism on a ring, film reel assembly and lifting mechanism which moves the ring up and down. Optional assemblies: conveyors, film clamp, film knife, film sealing device, hold-down plate, pre-stretching unit on the film reel assembly, top sheet feeder.

Figure 6 — Ring machine – Principle of operation

3.2.2.5 Semi automatic self driving pallet stretch wrapping machines Semi automatic self driving pallet stretch wrapping machines apply a stretch film by the whole machine driving around the product (see Figure 7). The machine is guided around the product by a contact wheel which is mounted on a moveable lever. The principle components are the contact wheel and the film reel assembly.

Key: 1 Contact wheel 2

Film reel assembly Figure 7 — Semi automatic self driving pallet stretch wrapping machine 3.2.2.6 Mobile pallet stretch wrapping machines Mobile stretching machines (see Figure 8) are moved to the pallet manually, usually assisted by a motor drive. Usually the pallet is lifted by a lifting mechanism and so fixed on the stretch wrapping machine. The machine wraps a product in film or net, from a reel on an arm which rotates around the stationary product (rotary arm machine). The principle components are: pallet support, rotary arm and film reel assembly.

Figure 8 — Mobile pallet stretch wrapping machine 3.2.3 Curtain stretching machine A conveyor transports the product into a film curtain that is stretched and subsequently welded on the rear side. Working principle is the so-called passage method according to which the product in the machine bumps against the film web rolling off two rollers and drags this along. In this manner, the stretch film envelopes the advancing product. After this a closing and cutting tool tightens up and separates the film (see Figure 9). The principle components are: conveyor, film reel assembly, sealing and cutting mechanism Optional assemblies: Top sheet assembly

Figure 9 — Curtain stretching machine – Principle of operation 3.2.4 Hood stretching machines Hood stretching machines apply a stretch film hood which is prefabricated or taken from a film tube roll to a product by stretching it and pulling it over the product. When a film tube is used, the required length of the hood is pulled off the reel then sealed and cut off. Hood stretching can be either semiautomatic or fully automatic. In case of semiautomatic hood stretching, the essential automatic operations are only gathering and stretching. The hood is loaded manually. Prefabricated hoods or hoods on reels with perforated separation seam are used.

Figure 10 — Hood stretching machine

Fully automatic machines use reels of square tubes with gussets or of flat tubes. The film web to be uncoiled is guided via deviation or dancer rolls into the head of the machine operating according to the vertical principle.

Mechanically, pneumatically or vacuum driven opening devices open the tube to a rectangular format and put it into the gathering device. Similar to the case with the semiautomatic version this device consists of gathering fingers. In one version, transfer of the forward end of the hood to the gathering fingers is made from top while it is made from the bottom in another version. The hood length needed is pulled off a roll in accordance with the stack height in each case, then welded and cut off. Once the hood has been gathered, the gathering devices move diagonally outward and stretch the hood film in horizontal direction. After the head area of the hood is put on the uppermost stack layer during the downward movement, the gathered hood is pulled off the gathering fingers so that different values for stretching in vertical position can be achieved.

3.2.5 Shrink film pallet wrapping machines 3.2.5.1 General When using the shrinking method, the product is first wrapped with thermoplastic film. Subsequently, the thermoplastic film is shrunk under the effect of heat around the pack. See 3.2.6 for descriptions of shrinking systems. 3.2.5.2 Banding, curtain and sleeve wrapping machines A conveyor transports product into a curtain of thermoplastic or non elastic film that is welded on the rear side. Working principle is the so-called passage method according to which, the product in the machine bumps against the film web rolling off two rollers and drags this along. In this manner, the film wraps the advancing product. Working principle see Figure 9. Differentiation is made between horizontal and vertical machines. In the horizontal machine the film reels are arranged in vertical position next to the product conveying system. In the vertical machine one film reel is positioned above and another one below the conveying system. The principle components are: conveyor, film reel assembly, film closing/fixing mechanism, cutting mechanism Optional assemblies: Top sheet assembly, sealing mechanism 3.2.5.3 Spiral pallet wrapping machines A spiral pallet wrapping machine (see Figure 12) processes a shrink film that is wound spirally around product and product carrier in the same way as by a pallet stretching machine, but without sufficient tension to stretch the film. This method allows packaging of product which varies in height or base, using one machine and one film width. See Figure 11. The principle components are: rotating table, film reel assembly and lifting mechanism which moves the film reel assembly vertically thus producing a spiral wrap. Optional assemblies: conveyors, film clamp, film knife, film sealing device, hold-down plate, pre-stretching unit on the film reel assembly, top sheet feeder.

Key 1 hold down plate

2 film reel assembly 3 rotary table

4 product Figure 11 — Spiral pallet wrapping machine 3.2.5.4 Hood application machines 3.2.5.4.1 General Hood application machines generally use a square profile tube with gussets. The machine detects the height of the product and forms the hood length accordingly. There are two principle operating types between two versions: vertical hood and parachute hood application, which are described below. 3.2.5.4.2 Vertical hood application machine The film hood is formed above the product and put on vertically, i.e. opening, welding and cutting device are located above the product (see Figure 13). Opening of the hood is usually assisted by a blower. After the hood has been put on, the product is fed to a shrinking device. The principle components are: tube film reel assembly, tube opening mechanism, tube placement mechanism, tube cutting device, hood application mechanism Optional assemblies: conveyors, edge protection feeding device, blower

Key 1 product

2 conveyor

3 film reels (two formats) Figure 12 — Vertical hood application machine

Key 1 film assembling unit

2 film reels (2No)

3 conveyor

4 product

5 turning arm Figure 13 — Parachute hood application machine 3.2.6 Shrinking systems 3.2.6.1 Shrinking frame, shrinking hood The shrinking frame (see Figure 14) shrinks a thermoplastic film around the product while the frame is guided over the surface of the product. Shrinking frames either have a single continuous heat outlet (e.g. slot along the frame) or multiple heat outlets (e.g. a number of air nozzles positioned along the frame). The heat source usually is electric energy or gas.

Shrinking hoods are rectangular containers with open bottom that are guided over a product enveloped with a thermoplastic film. They exist both with central heating device and continuously arranged heating elements.

In both cases the product is fed either manually or by a conveyor. The principle components are: frame or hood with a source of heat, lifting mechanism which moves the hood or frame up and down, heating system. Optional assemblies: conveyors.

Key 1 shrinking frame

2 moving frame mechanism

3 moving drive Figure 14 — Shrinking frame 3.2.6.2 Shrinking oven A shrinking oven is a heated space in which the thermoplastic film put around a product is shrunk. Shrinking ovens are available as chamber ovens (see Figure 15) or as continuous ovens (see Figure 16) as well. They can use direct gas heating, indirect oil heating or also be fitted with electrical heater coils. The principle components are: conveyors, source of heat, automatic doors. Optional assemblies: fans.

Key 1 fan circulating air 2 electric heating unit 3 bogie drive unit 4 bottom shrink device 5 automatic doors 6 conveyor A side view B plan view C end view TR product transport direction

Figure 15 — Chamber shrinking oven with electric heating device

Key 1 infeed conveyor 2 product position in oven 3 product position after shrink cycle 4 discharge conveyor 5 bottom shrink device 6 heating element 7 shrinking zone 8 automatic doors A side view B plan view C end view TR product transport direction

Figure 16 — Continuous shrinking oven using thermal combustion heating 3.2.6.3 Shrinking column Shrinking columns are devices in which a thermoplastic film is shrunk around product using heating devices that are positioned in usually one or two vertical columns at the side of a rotating table which can be part of a conveyor. Shrinking columns exist as rotating shrinking column with stationary product or as stationary shrinking column with rotating product. The heating device can be heated electrically or by means of gas. The principle components are: source of heat, turn table. Optional assemblies: conveyors.

Key 1 product 2 roller conveyor with turntable 3 column 4 heating elements Figure 17 — Shrinking column using thermal combustion 3.2.7 Auxiliary machines 3.2.7.1 Top sheet feeder To place the top sheet, one film sheet is put on top of product. The top sheet is pulled off a reel, cut off, drawn over product or put on it. Subsequently, the top sheet hanging down on the sides is enveloped using the spiral film winding method.

Differentiation is made between the following working methods: When working according to the passage principle, the top sheet feeder uncoils the top sheet from the roll while product is passing. Subsequently, the top sheet is cut off.

When working according to the tensioning principle, the top sheet is uncoiled from the reel, then pulled over the top of the stationary product, cut off and put down.

The principle components are: film reel assembly or top sheet magazine, application mechanism, gripping mechanism

film clamp, film cutting device. 3.2.7.2 Product centralising machines Product centralising machines push the product, usually placed on a pallet, in the correct position by pressing with two lateral metal plates. The machine usually is loaded automatically by a pallet conveyor. The principle components are: pushing plates, conveyor

Key 1 pushing plates 2 roller conveyor 3 product Figure 18 — Product centralizing machine 3.2.7.3 Film removing machines Film removing machines remove the film from palletised or unpalletised product. Usually the film is cut vertically by a cutting device and then removed by low pressure. Mostly a product centralising assembly is used to hold the product. The machine usually is loaded automatically by a pallet conveyor usually comprises an integrated lifting platform. The principle components are: cutting device, film removing assembly, film repository, conveyor with lifting platform. 4 List of hazards on pallet wrapping machines

4.1 General This clause lists all the significant hazards, hazardous situations and events that can be found on typical pallet wrapping machines including integrated transport, feed and discharge devices.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...