EN 12312-9:2005+A1:2009

(Main + Amendment)Aircraft ground support equipment - Specific requirements - Part 9: Container/Pallet loaders

Aircraft ground support equipment - Specific requirements - Part 9: Container/Pallet loaders

This document specifies the technical requirements to minimise the hazards listed in Clause 4 which can arise during the commissioning, operation and maintenance of container/pallet loaders when carried out in accordance with the specifications given by the manufacturer or his authorised representative. It also takes into account some performance requirements recognised as essential by authorities, aircraft and ground support equipment (GSE) manufacturers as well as airlines and handling agencies.

This document applies to:

- Container/Pallet loader (self-propelled) single platform;

- Container/Pallet loader (self-propelled) two platforms;

- Container/Pallet loader/transporter (self-propelled);

- Container/Pallet loader/transfer platform (towed).

Examples of some of the different types of loaders are shown in Annex B.

This document does not establish requirements for noise and vibration.

Noise and vibration are dealt with respectively in prEN 1915-4 and prEN 1915-3.

This standard does not deal with hazards in respect to a standard automotive chassis and from other vehicles on the apron.

This Part of EN 12312 is not applicable to container/pallet loaders which are manufactured before the date of publication of this document by CEN.

NOTE Certain measurements have been given in imperial units (in parentheses) following the metric measurements since the containers/pallets to be handled are based mainly on the imperial system.

This part of EN 12312 is intended to be used in conjunction with EN 1915-1, EN 1915-2, EN 1915-3 (for vehicles) and EN 1915-4.

Luftfahrt-Bodengeräte - Besondere Anforderungen - Teil 9: Container-/Paletten-Hubfahrzeuge

Matériel au sol pour aéronefs - Exigences particulières - Partie 9: Chargeurs de conteneurs/palettes

Podporna oprema na tleh za letalski promet - Posebne zahteve - 9. del: Nakladalniki zabojnikov/palet

General Information

- Status

- Withdrawn

- Publication Date

- 28-Apr-2009

- Withdrawal Date

- 22-Jan-2013

- Technical Committee

- CEN/TC 274 - Aircraft ground support equipment

- Drafting Committee

- CEN/TC 274/SC 2/WG 5 - Container/Pallet loaders

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 23-Jan-2013

- Completion Date

- 23-Jan-2013

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 30-Jan-2013

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 13850:2008 - Safety of machinery - Emergency stop - Principles for design (ISO 13850:2006) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 12312-9:2005+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Aircraft ground support equipment - Specific requirements - Part 9: Container/Pallet loaders". This standard covers: This document specifies the technical requirements to minimise the hazards listed in Clause 4 which can arise during the commissioning, operation and maintenance of container/pallet loaders when carried out in accordance with the specifications given by the manufacturer or his authorised representative. It also takes into account some performance requirements recognised as essential by authorities, aircraft and ground support equipment (GSE) manufacturers as well as airlines and handling agencies. This document applies to: - Container/Pallet loader (self-propelled) single platform; - Container/Pallet loader (self-propelled) two platforms; - Container/Pallet loader/transporter (self-propelled); - Container/Pallet loader/transfer platform (towed). Examples of some of the different types of loaders are shown in Annex B. This document does not establish requirements for noise and vibration. Noise and vibration are dealt with respectively in prEN 1915-4 and prEN 1915-3. This standard does not deal with hazards in respect to a standard automotive chassis and from other vehicles on the apron. This Part of EN 12312 is not applicable to container/pallet loaders which are manufactured before the date of publication of this document by CEN. NOTE Certain measurements have been given in imperial units (in parentheses) following the metric measurements since the containers/pallets to be handled are based mainly on the imperial system. This part of EN 12312 is intended to be used in conjunction with EN 1915-1, EN 1915-2, EN 1915-3 (for vehicles) and EN 1915-4.

This document specifies the technical requirements to minimise the hazards listed in Clause 4 which can arise during the commissioning, operation and maintenance of container/pallet loaders when carried out in accordance with the specifications given by the manufacturer or his authorised representative. It also takes into account some performance requirements recognised as essential by authorities, aircraft and ground support equipment (GSE) manufacturers as well as airlines and handling agencies. This document applies to: - Container/Pallet loader (self-propelled) single platform; - Container/Pallet loader (self-propelled) two platforms; - Container/Pallet loader/transporter (self-propelled); - Container/Pallet loader/transfer platform (towed). Examples of some of the different types of loaders are shown in Annex B. This document does not establish requirements for noise and vibration. Noise and vibration are dealt with respectively in prEN 1915-4 and prEN 1915-3. This standard does not deal with hazards in respect to a standard automotive chassis and from other vehicles on the apron. This Part of EN 12312 is not applicable to container/pallet loaders which are manufactured before the date of publication of this document by CEN. NOTE Certain measurements have been given in imperial units (in parentheses) following the metric measurements since the containers/pallets to be handled are based mainly on the imperial system. This part of EN 12312 is intended to be used in conjunction with EN 1915-1, EN 1915-2, EN 1915-3 (for vehicles) and EN 1915-4.

EN 12312-9:2005+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 49.100 - Ground service and maintenance equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12312-9:2005+A1:2009 has the following relationships with other standards: It is inter standard links to EN 12312-9:2005, EN 12312-9:2005/prA1, EN 12312-9:2013, EN 1915-2:2001+A1:2009, EN 1915-3:2004+A1:2009, EN ISO 13850:2008, EN 4165-027:2015, EN ISO 12100-2:2003, EN 1837:2020, EN 1915-1:2001, EN ISO 12100-1:2003, EN 1915-4:2004+A1:2009, EN 1050:1996, EN 954-1:1996. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12312-9:2005+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12312-9:2005+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Podporna oprema na tleh za letalski promet - Posebne zahteve - 9. del: Nakladalniki zabojnikov/paletLuftfahrt-Bodengeräte - Besondere Anforderungen - Teil 9: Container-/Paletten-HubfahrzeugeMatériel au sol pour aéronefs - Exigences particulières - Partie 9: Chargeurs de

conteneurs/palettesAircraft ground support equipment - Specific requirements - Part 9: Container/Pallet loaders55.180.01Distribucija blaga s prevozom na splošnoFreight distribution of goods in general49.120Oprema za tovorCargo equipmentICS:Ta slovenski standard je istoveten z:EN 12312-9:2005+A1:2009SIST EN 12312-9:2005+A1:2009en01-julij-2009SIST EN 12312-9:2005+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12312-9:2005+A1

April 2009 ICS 49.100 Supersedes EN 12312-9:2005English Version

Aircraft ground support equipment - Specific requirements - Part 9: Container/Pallet loaders

Matériel au sol pour aéronefs - Exigences particulières - Partie 9: Chargeurs de conteneurs/palettes

Luftfahrt-Bodengeräte - Besondere Anforderungen - Teil 9: Container-/Paletten-Hubfahrzeuge This European Standard was approved by CEN on 21 March 2005 and includes Amendment 1 approved by CEN on 1 March 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12312-9:2005+A1:2009: ESIST EN 12312-9:2005+A1:2009

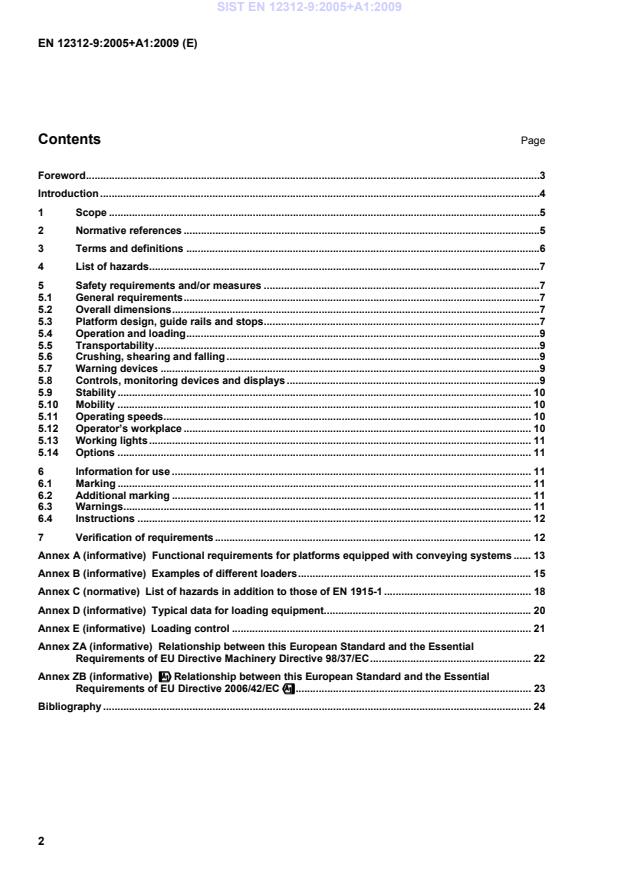

2 Contents Page Foreword .3Introduction .41Scope .52Normative references .53Terms and definitions .64List of hazards .75Safety requirements and/or measures .75.1General requirements .75.2Overall dimensions .75.3Platform design, guide rails and stops.75.4Operation and loading .95.5Transportability .95.6Crushing, shearing and falling .95.7Warning devices .95.8Controls, monitoring devices and displays .95.9Stability . 105.10Mobility . 105.11Operating speeds. 105.12Operator’s workplace . 105.13Working lights . 115.14Options . 116Information for use . 116.1Marking . 116.2Additional marking . 116.3Warnings . 116.4Instructions . 127Verification of requirements . 12Annex A (informative)

Functional requirements for platforms equipped with conveying systems . 13Annex B (informative)

Examples of different loaders . 15Annex C (normative)

List of hazards in addition to those of EN 1915-1 . 18Annex D (informative)

Typical data for loading equipment. 20Annex E (informative)

Loading control . 21Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive Machinery Directive 98/37/EC . 22Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 23Bibliography . 24 SIST EN 12312-9:2005+A1:2009

4 Introduction This document specifies health and safety requirements, as well as some functional and performance requirements for container/pallet loaders intended for loading/unloading of unit loads with the exception of bulk material for all aircraft types commonly in service in civil air transport. The minimum essential criteria are considered to be of primary importance in providing safe, serviceable, economical and practical container/pallet loaders. Deviations from the recommended criteria should occur only after careful consideration, extensive testing, risk assessment and thorough service evaluation have shown alternative methods or conditions to be satisfactory. This document is a Type C standard as stated in !EN ISO 12100". The machinery concerned and the extent to which hazards, hazardous situations and events are covered are indicated in the scope of this document. When provisions of this type C standard are different from those which are stated in type A or B standards, the provisions of this type C standard take precedence over the provisions of the other standards, for machines that have been designed and built according to the provisions of this type C standard. For information, a summary of equipment functional design requirements covered by International Standards, e.g. ISO 6967 and ISO 6968, and IATA Airport Handling Manual are given in Annex A. SIST EN 12312-9:2005+A1:2009

6 EN 1915-4, Aircraft ground support equipment — General requirements — Part 4: Noise measurement meth-ods and reduction" EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles (ISO 12100-2:2003) !EN ISO 13850:2008, Safety of machinery — Emergency stop — Principles for design (ISO 13850:2006)" !ISO 2328", Fork lift trucks — Hook on type fork arms and fork arm carriages — Mounting dimensions 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 12100:2003 and

EN 1915-1:2001 and the following apply. 3.1 loader vehicle having a prime purpose of lifting, lowering and transferring unit load devices (ULD's), also known as an elevator 3.2 single platform loader loader which only has a single lifting platform 3.3 wide body aircraft nose loader single or two platform loader which interfaces with the nose opening of a wide body aircraft 3.4 two platform loader loader having a front platform and a main platform 3.5 tail loader loader which interfaces with the

tail opening of the aircraft 3.6 main platform load bearing device which interfaces with the aircraft on a single platform loader or with the front platform of a two platform loader, and with ground transportation systems 3.7 front platform load bearing device which interfaces with the aircraft on a two platform loader, also known as a transfer plat-form or bridge 3.8 lower deck aircraft compartment below the main deck SIST EN 12312-9:2005+A1:2009

EN 1915-3 and EN 1915-4 unless otherwise specified in this standard." They shall also conform to the spe-cific requirements of this document. 5.1.2 Strength calculations shall be carried out in accordance with !EN 1915-2." 5.2 Overall dimensions The overall dimensions of the loader shall be kept to a minimum, consistent with its function in handling the loads described in Annex D, and in accordance with the requirements of 5.4. The overall height of the entire loader shall not exceed 4,0 m, when being driven with the platform(s) in the lowest position. 5.3 Platform design, guide rails and stops 5.3.1 Platform types Depending on the type, loaders may have one or two platforms. Single platform loaders shall provide a platform which is capable of up and down movement between the heights given in Annex D, as appropriate to the type(s) of container/pallets to be handled. Two-platform loaders shall provide: SIST EN 12312-9:2005+A1:2009

8 a front platform which is positioned adjacent to the aircraft door and which remains at this position during the loading/unloading operation, or, for main deck operation, may be lowered to a lower deck position to interface with the main platform; and a main platform, for up and down movement between the heights given in Annex D as appropriate to the type(s) of containers/pallets to be handled. 5.3.2 Guide rails and stops 5.3.2.1 Guide rails shall be provided along the whole length of both sides of the platform to guide containers/pallets onto the aircraft and to prevent them from falling off. On single platforms and the front platform of two-platform loaders they shall be adjustable laterally to align with the corresponding in-aircraft guides. On container-only loaders, guide rails may be fixed. Powered guide rails shall consist of either one or more sections and for each section be able to operate independently. All powered guide rails shall be in the “up” position when the main platform raises more than 150 mm from the rest position. For the transfer of loads, it should be possible for the operator to control the retraction/removal of the guide rails on the main platform, at any height of the main platform between 1 524 mm and the fully lowered position. 5.3.2.2 Stops shall be provided as follows: on the front platform of a two-platform loader, automatic stops shall be fitted at the end adjacent to the main platform. These stops shall rise when the main platform moves down and retract when the main platform reaches the front platform level; for loaders designed for main deck operation, and where the front platform is lowered to the lower deck position for interface with the main platform, stops shall be provided at the forward end of the front plat-form; automatic stops shall be provided at the rear end of the main platform of a two-platform loader. An auto-matic stop shall be provided at the forward end in order to prevent overhanging pallet loads or container contours to interfere with the front platform; on a single platform, retractable stops shall be provided at both ends; where the stops on the rear end of a main platform of a two platform loader are capable of being manually controlled, it shall only be possible to retract the stops when the main platform is stopped at any height between the fully lowered position and 1 524 mm (60 in) above the ground; where stops are provided at the forward end of the main platform or at the separation between two powered sections of the main platform, the forward end stop shall automatically retract as the main platform lines up with the front platform. The stop between the sections shall be controlled independently by the operator. 5.3.2.3 All stops and guide rails shall have a minimum height of 50 mm (2 in) above the conveying surface. NOTE For the majority of containers and pallets, a maximum height of 100 mm (4 in) is required to avoid damage to overhanging loads or the sloping undersides of some containers. For certain lower deck containers, the maximum height becomes 50 mm (2 in). The maximum height should take into account the types of containers to be handled. SIST EN 12312-9:2005+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...