EN 1175:2025

(Main)Safety of industrial trucks - Electrical/electronic requirements

Safety of industrial trucks - Electrical/electronic requirements

This document specifies the electrical requirements for the design and construction of the electrical installation in self-propelled industrial trucks that are within the scope of ISO 5053-1:2020, except rough-terrain variable-reach trucks as defined in ISO 5053-1:2020, 3.21 and 3.22, straddle carriers as defined in ISO 5053-1:2020, 3.18 and 3.19, and all those functions utilized for the automatic operation of driverless industrial trucks as defined in ISO 5053-1:2020, 3.32. It provides the electrical/electronic and safety-related parts of control system requirements for those self-propelled industrial trucks identified above.

NOTE 1 For detailed information about the electrical/electronic requirements for driverless trucks see EN ISO 3691-4:2023, 4.1.3.

NOTE 2 Reference is made to this document in other standards which cover the non-electrical requirements of the various industrial truck types.

This document deals with safety requirements for all electrical and electronic components of industrial trucks, including electrically actuated hydraulic/pneumatic valves. It specifies minimum performance levels required for safety functions realized by safety related parts of control systems. It is intended to be used to avoid or minimize hazards or hazardous situations listed in Annex I. These situations can arise during the operation in the area of use for which it is designed and during maintenance of trucks in accordance with the specifications and instruction given by the manufacturer.

This document does not deal with hazards which could occur:

- during construction;

- when operating in potentially explosive atmospheres;

- because of malfunction of non-electric safety-related parts of control systems, e.g. hydraulic and pneumatic elements like pistons, non-electric valves, pumps, etc.;

- when operating outside the range of 30 % to 95 % (not condensing) of relative humidity.

NOTE 3 The level of the defined required performance for electrical safety related control systems can be used as a guideline to determine the performance of non-electric systems.

NOTE 4 Hazards due to penetration of water and dust are covered by the definition of PLr of safety functions, according to EN ISO 13849-1:2023.

NOTE 5 Safety measures outside the scope of the electrical/electronic system are covered by other safety standards e.g. EN ISO 3691 series and EN 16307 series.

Sicherheit von Flurförderzeugen - Elektrische/elektronische Anforderungen

Dieses Dokument legt die elektrischen Anforderungen für die Auslegung und die Herstellung der elektrischen Anlage von selbstfahrenden Flurförderzeugen im Anwendungsbereich von ISO 5053-1:2020 fest, mit Ausnahme von Flurförderzeugen mit veränderlicher Reichweite wie in ISO 5053-1:2020, 3.21 und 3.22 definiert, Portalhubwagen wie in ISO 5053-1:2020, 3.18 und 3.19 definiert und spezifischen Funktionen, Teilen und/oder Systemen für den automatischen Betrieb von fahrerlosen Flurförderzeugen wie in ISO 5053-1:2020, 3.32 definiert. Es stellt die elektrischen/elektronischen und sicherheitsbezogenen Teile der Anforderungen an die Steuerungssysteme für die genannten selbstfahrenden Flurförderzeuge zur Verfügung.

ANMERKUNG 1 Auf dieses Dokument wird in anderen Normen, die die nichtelektrischen Anforderungen verschiedener Typen von Flurförderzeugen behandeln, Bezug genommen.

Dieses Dokument behandelt Sicherheitsanforderungen für alle elektrischen und elektronischen Komponenten von Flurförderzeugen einschließlich elektrisch betätigter Hydraulik-/Pneumatikventile. Es legt die Mindest-Performance Level für Sicherheitsfunktionen fest, die von sicherheitsbezogenen Teilen von Steuerungen realisiert werden. Es soll die in Anhang I aufgeführten Gefährdungen oder Gefährdungssituationen verhindern oder so gering wie möglich halten. Diese Situationen können beim Betrieb in dem nach der Auslegung bestimmten Einsatzbereich entstehen und bei der Instandhaltung von Flurförderzeugen entsprechend den Spezifikationen und Anweisungen des Herstellers.

Dieses Dokument behandelt keine Gefährdungen, die auftreten könnten:

a) während der Herstellung;

b) bei Betrieb in explosionsgefährdeten Bereichen;

c) aufgrund einer Fehlfunktion von nicht sicherheitsbezogenen elektrischen Teilen von Steuerungssystemen, z. B. hydraulischen und pneumatischen Elementen wie Kolben, nichtelektrische Ventile, Pumpen usw.;

d) bei Betrieb außerhalb des Bereichs von 30 % bis 95 % (ohne Betauung) relativer Luftfeuchte.

ANMERKUNG 2 Die für sicherheitsbezogene elektrische Steuerungssysteme definierten erforderlichen Performance-Level können als Leitfaden für die Festlegung der Performance von nichtelektrischen Systemen verwendet werden.

ANMERKUNG 3 Gefährdungen durch Eindringen von Wasser und Staub sind durch die Definition von PLr von Sicherheitsfunktionen nach EN ISO 13849-1:2015 abgedeckt.

Sécurité des chariots de manutention - Exigences électriques/électroniques

Le présent document spécifie les exigences électriques pour la conception et à la fabrication de l'installation électrique dans les chariots de manutention automoteurs relevant du domaine d'application de l'ISO 5053-1:2020, à l'exception des chariots tout-terrain à portée variable définis dans l'ISO 5053-1:2020, 3.21 et 3.22, des chariots cavaliers définis dans l'ISO 5053-1:2020, 3.18 et 3.19, et toutes ces fonctions servant au fonctionnement automatique des chariots de manutention sans conducteur définis dans l'ISO 5053-1:2015, 3.32. Il fournit les exigences applicables aux parties électriques/électroniques et relatives à la sécurité du système de commande pour les chariots de manutention automoteurs identifiés ci dessus.

NOTE 1 Pour des informations détaillées concernant les exigences électriques/électroniques pour les chariots sans conducteurs voir l’EN ISO 3691-4 :2023, 4.1.3.

NOTE 2 Il est fait référence au présent document dans d'autres normes traitant des exigences relatives aux différents types de chariots de manutention dans des domaines autres que l'électricité.

Le présent document traite des exigences de sécurité s'appliquant à tous les composants électriques et électroniques des chariots de manutention, y compris les distributeurs hydrauliques/pneumatiques électriques. Il spécifie les niveaux de performance minimaux requis pour les fonctions de sécurité réalisées par les parties des systèmes de commande relatives à la sécurité. Il est destiné à être utilisé afin d'éviter ou de réduire au minimum les phénomènes dangereux ou les situations dangereuses énumérés à l'Annexe I. Ces situations peuvent survenir pendant l'utilisation dans la zone à laquelle ils sont destinés et pendant la maintenance des chariots conformément aux spécifications et aux instructions données par le fabricant.

Le présent document ne traite pas des phénomènes dangereux qui peuvent se produire :

- pendant la fabrication ;

- lors du fonctionnement dans des atmosphères explosibles ;

- en raison d'un dysfonctionnement des parties relatives à la sécurité non électriques des systèmes de commande, par exemple, des éléments hydrauliques et pneumatiques tels que les pistons, les distributeurs non électriques, les pompes, etc. ;

- en cas de fonctionnement en dehors de la plage de 30 % à 95 % (sans condensation) d'humidité relative.

NOTE 3 Le niveau de performance requis défini pour les systèmes de commande relatifs à la sécurité électriques peut servir de ligne directrice pour déterminer les performances des systèmes non électriques.

NOTE 4 Les phénomènes dangereux dus à la pénétration d'eau et de poussière sont couverts par la définition du PLr des fonctions de sécurité, conformément à l’EN ISO 13849-1:2023.

NOTE 5 Les mesures de sécurité en dehors du domaine d'application du système électrique/électronique sont couvertes par d'autres normes de sécurité, par exemple, la série EN ISO 3691 et la série EN 16307.

Varnost vozil za talni transport - Električne/elektronske zahteve

General Information

- Status

- Published

- Publication Date

- 18-Nov-2025

- Technical Committee

- CEN/TC 150 - Industrial trucks - Safety

- Drafting Committee

- CEN/TC 150/WG 10 - Electromagnetic compatibilty

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 19-Nov-2025

- Due Date

- 12-Jul-2024

- Completion Date

- 19-Nov-2025

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1175:2025 - Safety of industrial trucks: Electrical/electronic requirements (CEN) specifies the electrical and electronic design and construction requirements for self‑propelled industrial trucks within the scope of ISO 5053-1:2020. The standard focuses on electrical/electronic safety-related parts of control systems, defining minimum performance levels for safety functions to avoid or minimize hazards during normal operation and maintenance. It excludes certain vehicle types and functions (e.g., rough‑terrain variable‑reach trucks, straddle carriers, and automatic functions for driverless trucks). Note: driverless truck electrical requirements are covered by EN ISO 3691‑4:2023.

Key topics and technical requirements

- Safety functions & validation: Requirements emphasize validation and verification of safety functions and safety‑related parts of control systems, aligned with EN ISO 13849‑1 principles.

- Energy sources: Rules for battery systems (lead‑acid, lithium‑ion), connectors, interoperability and connector type‑testing (Annexes A, C).

- Travel, braking and steering controls: Electrical requirements for propulsion, braking, steering (including assisted and backup systems) and related protective measures.

- Electrical load‑handling: Safety of electrically actuated hydraulic/pneumatic valves and load control electronics.

- High‑voltage trucks: Additional requirements for HV systems - battery design, protection against electric shock and related markings.

- Software design: Requirements for control software used in safety functions, including validation and documentation.

- Component specifications and tests: Detailed annexes for contactors, conductors/cables, electric drive systems and electromagnetic compatibility.

- Environmental limits and exclusions: Applies within 30% to 95% relative humidity (non‑condensing); does not cover potentially explosive atmospheres or construction-phase hazards.

- Informative material: Annexes include list of significant hazards (Annex I) and cross‑references to truck types (Annex H).

Practical applications

EN 1175:2025 is used to:

- Guide electrical design for industrial truck manufacturers to meet safety performance levels.

- Define testing and inspection criteria for components (batteries, contactors, cables).

- Support risk reduction measures for maintenance teams and safety engineers.

- Serve as a technical basis for conformity assessment and market surveillance for electrical safety of trucks.

Who should use this standard

- Industrial truck manufacturers and OEM electrical engineers

- Safety and compliance officers, test laboratories, and certification bodies

- Regulators, workplace safety professionals, and maintenance/service providers

Related standards

- ISO 5053‑1:2020 (truck types/vocabulary)

- EN ISO 3691 series (vehicle safety, driverless trucks guidance EN ISO 3691‑4:2023)

- EN ISO 13849‑1 (safety‑related parts of control systems)

- EN 60204‑1 (electrical equipment of machines)

- EN 16307 series (supplementary safety requirements)

Keywords: EN 1175:2025, industrial trucks, electrical requirements, safety functions, CEN, battery connectors, high‑voltage trucks, control systems, EN ISO 13849‑1.

Frequently Asked Questions

EN 1175:2025 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of industrial trucks - Electrical/electronic requirements". This standard covers: This document specifies the electrical requirements for the design and construction of the electrical installation in self-propelled industrial trucks that are within the scope of ISO 5053-1:2020, except rough-terrain variable-reach trucks as defined in ISO 5053-1:2020, 3.21 and 3.22, straddle carriers as defined in ISO 5053-1:2020, 3.18 and 3.19, and all those functions utilized for the automatic operation of driverless industrial trucks as defined in ISO 5053-1:2020, 3.32. It provides the electrical/electronic and safety-related parts of control system requirements for those self-propelled industrial trucks identified above. NOTE 1 For detailed information about the electrical/electronic requirements for driverless trucks see EN ISO 3691-4:2023, 4.1.3. NOTE 2 Reference is made to this document in other standards which cover the non-electrical requirements of the various industrial truck types. This document deals with safety requirements for all electrical and electronic components of industrial trucks, including electrically actuated hydraulic/pneumatic valves. It specifies minimum performance levels required for safety functions realized by safety related parts of control systems. It is intended to be used to avoid or minimize hazards or hazardous situations listed in Annex I. These situations can arise during the operation in the area of use for which it is designed and during maintenance of trucks in accordance with the specifications and instruction given by the manufacturer. This document does not deal with hazards which could occur: - during construction; - when operating in potentially explosive atmospheres; - because of malfunction of non-electric safety-related parts of control systems, e.g. hydraulic and pneumatic elements like pistons, non-electric valves, pumps, etc.; - when operating outside the range of 30 % to 95 % (not condensing) of relative humidity. NOTE 3 The level of the defined required performance for electrical safety related control systems can be used as a guideline to determine the performance of non-electric systems. NOTE 4 Hazards due to penetration of water and dust are covered by the definition of PLr of safety functions, according to EN ISO 13849-1:2023. NOTE 5 Safety measures outside the scope of the electrical/electronic system are covered by other safety standards e.g. EN ISO 3691 series and EN 16307 series.

This document specifies the electrical requirements for the design and construction of the electrical installation in self-propelled industrial trucks that are within the scope of ISO 5053-1:2020, except rough-terrain variable-reach trucks as defined in ISO 5053-1:2020, 3.21 and 3.22, straddle carriers as defined in ISO 5053-1:2020, 3.18 and 3.19, and all those functions utilized for the automatic operation of driverless industrial trucks as defined in ISO 5053-1:2020, 3.32. It provides the electrical/electronic and safety-related parts of control system requirements for those self-propelled industrial trucks identified above. NOTE 1 For detailed information about the electrical/electronic requirements for driverless trucks see EN ISO 3691-4:2023, 4.1.3. NOTE 2 Reference is made to this document in other standards which cover the non-electrical requirements of the various industrial truck types. This document deals with safety requirements for all electrical and electronic components of industrial trucks, including electrically actuated hydraulic/pneumatic valves. It specifies minimum performance levels required for safety functions realized by safety related parts of control systems. It is intended to be used to avoid or minimize hazards or hazardous situations listed in Annex I. These situations can arise during the operation in the area of use for which it is designed and during maintenance of trucks in accordance with the specifications and instruction given by the manufacturer. This document does not deal with hazards which could occur: - during construction; - when operating in potentially explosive atmospheres; - because of malfunction of non-electric safety-related parts of control systems, e.g. hydraulic and pneumatic elements like pistons, non-electric valves, pumps, etc.; - when operating outside the range of 30 % to 95 % (not condensing) of relative humidity. NOTE 3 The level of the defined required performance for electrical safety related control systems can be used as a guideline to determine the performance of non-electric systems. NOTE 4 Hazards due to penetration of water and dust are covered by the definition of PLr of safety functions, according to EN ISO 13849-1:2023. NOTE 5 Safety measures outside the scope of the electrical/electronic system are covered by other safety standards e.g. EN ISO 3691 series and EN 16307 series.

EN 1175:2025 is classified under the following ICS (International Classification for Standards) categories: 53.060 - Industrial trucks. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1175:2025 has the following relationships with other standards: It is inter standard links to EN 1175:2020, EN ISO 3691-2:2023, EN ISO 6743-4:2015, EN ISO 20127:2025, EN 16307-1:2020, EN ISO 13849-1:2023, EN ISO 3691-6:2021, EN ISO 3691-1:2015, EN ISO 3691-3:2016/A1:2023, EN 12895:2015+A1:2019, EN ISO 3691-1:2015/A1:2020, EN ISO 3691-3:2016, EN ISO 12100:2010, EN 12312-15:2006+A1:2009, EN 12312-8:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1175:2025 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1175:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2026

Nadomešča:

SIST EN 1175:2020

Varnost vozil za talni transport - Električne/elektronske zahteve

Safety of industrial trucks - Electrical/electronic requirements

Sicherheit von Flurförderzeugen - Elektrische/elektronische Anforderungen

Sécurité des chariots de manutention - Prescriptions électriques/électroniques

Ta slovenski standard je istoveten z: EN 1175:2025

ICS:

53.060 Industrijski tovornjaki Industrial trucks

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1175

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2025

EUROPÄISCHE NORM

ICS 53.060 Supersedes EN 1175:2020

English Version

Safety of industrial trucks - Electrical/electronic

requirements

Sécurité des chariots de manutention - Exigences Sicherheit von Flurförderzeugen -

électriques/électroniques Elektrische/elektronische Anforderungen

This European Standard was approved by CEN on 25 May 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1175:2025 E

worldwide for CEN national Members.

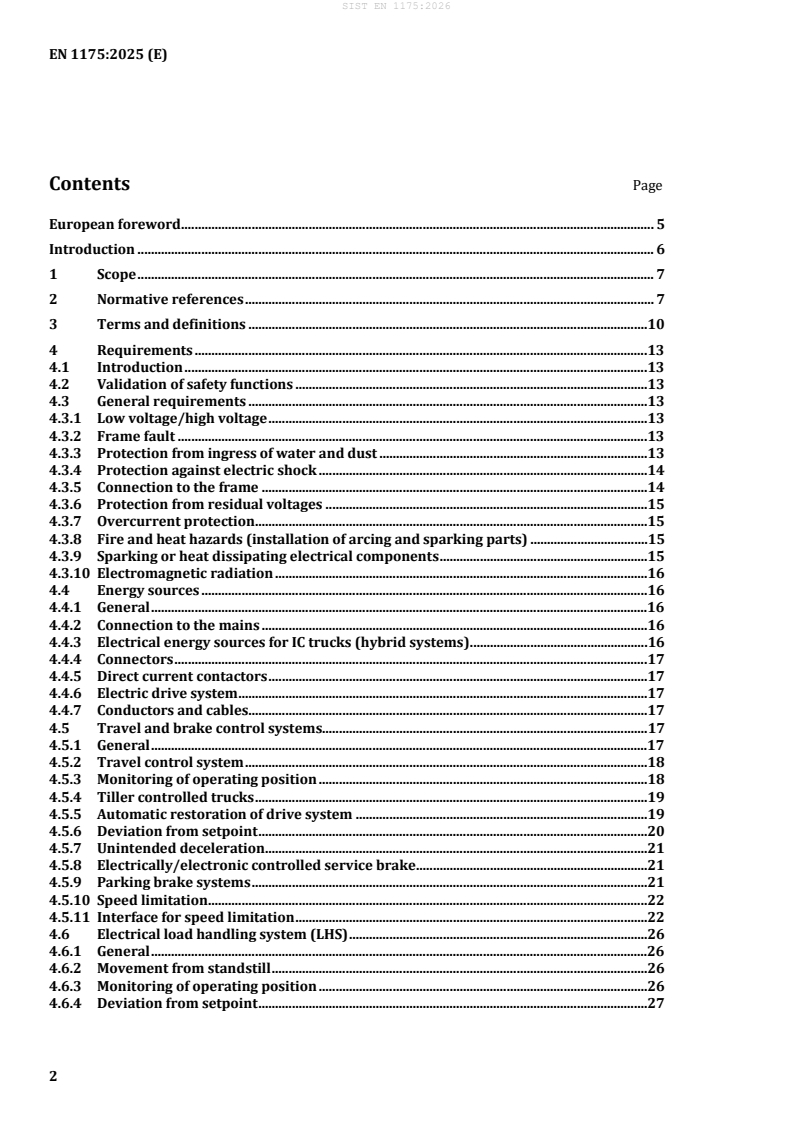

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions .10

4 Requirements .13

4.1 Introduction .13

4.2 Validation of safety functions .13

4.3 General requirements .13

4.3.1 Low voltage/high voltage .13

4.3.2 Frame fault .13

4.3.3 Protection from ingress of water and dust .13

4.3.4 Protection against electric shock .14

4.3.5 Connection to the frame .14

4.3.6 Protection from residual voltages .15

4.3.7 Overcurrent protection .15

4.3.8 Fire and heat hazards (installation of arcing and sparking parts) .15

4.3.9 Sparking or heat dissipating electrical components .15

4.3.10 Electromagnetic radiation .16

4.4 Energy sources .16

4.4.1 General .16

4.4.2 Connection to the mains .16

4.4.3 Electrical energy sources for IC trucks (hybrid systems) .16

4.4.4 Connectors .17

4.4.5 Direct current contactors .17

4.4.6 Electric drive system .17

4.4.7 Conductors and cables.17

4.5 Travel and brake control systems.17

4.5.1 General .17

4.5.2 Travel control system .18

4.5.3 Monitoring of operating position .18

4.5.4 Tiller controlled trucks .19

4.5.5 Automatic restoration of drive system .19

4.5.6 Deviation from setpoint .20

4.5.7 Unintended deceleration .21

4.5.8 Electrically/electronic controlled service brake .21

4.5.9 Parking brake systems .21

4.5.10 Speed limitation .22

4.5.11 Interface for speed limitation .22

4.6 Electrical load handling system (LHS) .26

4.6.1 General .26

4.6.2 Movement from standstill .26

4.6.3 Monitoring of operating position .26

4.6.4 Deviation from setpoint .27

4.6.5 Load clamp devices . 27

4.6.6 Limitation of load movement functions . 27

4.7 Steering . 29

4.7.1 General . 29

4.7.2 Electrical/electronic steering . 29

4.7.3 Electrically powered assisted steering systems . 30

4.8 Software design . 32

4.8.1 General . 32

4.8.2 Symbols and languages for user interfaces, service interfaces and keypads . 32

4.8.3 Parameters . 32

4.9 Other protective measures . 32

4.9.1 Switching off . 32

4.9.2 General purpose devices . 33

4.9.3 Other safety functions . 34

4.9.4 Dielectric test (type test) . 34

4.9.5 Insulation test (routine test) . 35

4.9.6 Insulation test (routine test) for high voltage trucks . 36

4.9.7 Frame fault test . 36

5 Additional requirements for high voltage trucks . 36

5.1 General . 36

5.2 Battery . 36

5.2.1 General . 36

5.2.2 Charger switching . 36

5.2.3 Requirements . 37

5.2.4 Emergency disconnection . 37

5.3 Protection against electric shock . 37

5.3.1 Electrical enclosures . 37

5.3.2 Circuits . 37

5.3.3 Bonding . 37

5.3.4 Detection of frame fault . 37

6 Information for use . 39

6.1 General . 39

6.2 Electrical diagram . 39

6.3 Electrical interface for external systems . 39

6.4 Safety checks . 39

6.5 Capacitors . 39

6.6 Marking . 39

6.6.1 General . 39

6.6.2 Electronic controller . 39

6.7 Non-ionising radiation . 39

6.8 Interoperability of energy sources. 40

Annex A (normative) Connectors for energy sources . 41

A.1 General . 41

A.2 Terms and definitions . 41

A.3 Requirements . 41

A.4 Type-test methods . 43

A.5 Quality assurance . 46

A.6 Information for use . 46

Annex B (normative) Electromagnetic contactors .47

B.1 General .47

B.2 Terms and definitions .47

B.3 Types of contactors.48

B.4 Product information .49

B.5 Normal service, mounting and transport conditions .50

B.6 Constructional and performance requirements .50

B.7 Tests .52

B.8 General test conditions .60

Annex C (normative) Energy sources .61

C.1 Lead-acid batteries .61

C.2 Lithium-ion batteries .62

Annex D (normative) Electric drive system (motors, converters, generators, energy sources)

....................................................................................................................................................................68

D.1 General .68

D.2 Special requirements .68

D.3 Testing .69

Annex E (normative) Assistance systems .70

E.1 General .70

E.2 Requirements .70

E.3 Information for use .71

Annex F (informative) Steering systems .72

F.1 General .72

F.2 Electric steering without backup .72

F.3 Electric steering with backup .73

F.4 Assisted steering systems .75

Annex G (normative) Conductors and cables .76

G.1 General .76

G.2 Protection .76

G.3 Cross-sectional area .76

G.4 Wiring practices .77

Annex H (informative) Cross reference with industrial truck types of ISO 5053-1:2020 .78

Annex I (informative) List of significant hazards .81

Annex J (informative) Explanations of safety functions .92

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered .97

Bibliography . 100

European foreword

This document (EN 1175:2025) has been prepared by Technical Committee CEN/TC 150 “Industrial

trucks - Safety”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2026, and conflicting national standards shall be

withdrawn at the latest by May 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1175:2020.

This document specifies up-to-date requirements for electric/electronic installations of industrial trucks.

Requirements are mainly based on safety functions and not only on safety related parts and take into

account exclusively electric/electronic elements.

The main changes compared to EN 1175:2020 are:

— updating of normative and informative references;

— added references to EN ISO 3691-2:2023, to EN ISO 3691-3:2016, to EN ISO 3691-6:2021.

— correction of the specification in transport test for contactors in Annex B;

— updating of Table 5.

This document is intended to be used in conjunction with EN ISO 3691 series and EN 16307 series.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100:2010.

This document is of relevance for the following stakeholder groups representing the market players with

regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the Scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or type-B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

1 Scope

This document specifies the electrical requirements for the design and construction of the electrical

installation in self-propelled industrial trucks that are within the scope of ISO 5053-1:2020, except rough-

terrain variable-reach trucks as defined in ISO 5053-1:2020, 3.21 and 3.22, straddle carriers as defined

in ISO 5053-1:2020, 3.18 and 3.19, and all those functions utilized for the automatic operation of

driverless industrial trucks as defined in ISO 5053-1:2020, 3.32. It provides the electrical/electronic and

safety-related parts of control system requirements for those self-propelled industrial trucks identified

above.

NOTE 1 For detailed information about the electrical/electronic requirements for driverless trucks see EN ISO

3691-4:2023, 4.1.3.

NOTE 2 Reference is made to this document in other standards which cover the non-electrical requirements of

the various industrial truck types.

This document deals with safety requirements for all electrical and electronic components of industrial

trucks, including electrically actuated hydraulic/pneumatic valves. It specifies minimum performance

levels required for safety functions realized by safety related parts of control systems. It is intended to be

used to avoid or minimize hazards or hazardous situations listed in Annex I. These situations can arise

during the operation in the area of use for which it is designed and during maintenance of trucks in

accordance with the specifications and instruction given by the manufacturer.

This document does not deal with hazards which could occur:

— during construction;

— when operating in potentially explosive atmospheres;

— because of malfunction of non-electric safety-related parts of control systems, e.g. hydraulic and

pneumatic elements like pistons, non-electric valves, pumps, etc.;

— when operating outside the range of 30 % to 95 % (not condensing) of relative humidity.

NOTE 3 The level of the defined required performance for electrical safety related control systems can be used

as a guideline to determine the performance of non-electric systems.

NOTE 4 Hazards due to penetration of water and dust are covered by the definition of PL of safety functions,

r

according to EN ISO 13849-1:2023.

NOTE 5 Safety measures outside the scope of the electrical/electronic system are covered by other safety

standards e.g. EN ISO 3691 series and EN 16307 series.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12895:2015+A1:2019, Industrial trucks — Electromagnetic compatibility

EN 16307-1:2020, Industrial trucks — Safety requirements and verification — Part 1: Supplementary

requirements for self-propelled industrial trucks, other than driverless trucks, variable-reach trucks and

burden-carrier trucks

EN 50565-1:2014, Electric cables — Guide to use for cables with a rated voltage not exceeding 450/750 V

(U0/U) — Part 1: General guidance

EN 60034-8:2007, Rotating electrical machines — Part 8: Terminal markings and direction of rotation

(IEC 60034-8:2007)

EN 60068-2-27:2009, Environmental testing — Part 2-27: Tests — Test Ea and guidance: Shock

(IEC 60068-2-27:2008)

EN 60068-2-6:2008, Environmental testing — Part 2-6: Tests — Test Fc: Vibration (sinusoidal)

(IEC 60068-2-6:2007)

EN 60204-1:2018, Safety of machinery — Electrical equipment of machines — Part 1: General

requirements

EN 60332-1-2:2004, Tests on electric and optical fibre cables under fire conditions — Part 1-2: Test for

vertical flame propagation for a single insulated wire or cable — Procedure for 1 kW pre-mixed flame

(IEC 60332-1-2:2004)

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 60695-11-10:2013, Fire hazard testing — Part 11-10: Test flames — 50 W horizontal and vertical

flame test methods (IEC 60695-11-10:2013)

EN 60947-5-5:1997, Low-voltage switchgear and controlgear — Part 5-5: Control circuit devices and

switching elements — Electrical emergency stop device with mechanical latching function

(IEC 60947-5-5:1997)

EN 61643-11:2012, Low-voltage surge protective devices — Part 11: Surge protective devices connected

to low-voltage power systems — Requirements and test methods (IEC 61643-11:2011)

EN 62485-3:2014, Safety requirements for secondary batteries and battery installations — Part 3: Traction

batteries (IEC 62485-3:2014)

EN 62620:2015, Secondary cells and batteries containing alkaline or other non-acid electrolytes —

Secondary lithium cells and batteries for use in industrial applications (IEC 62620:2014)

EN IEC 60384-14:2023, Fixed capacitors for use in electronic equipment — Part 14: Sectional specification

— Fixed capacitors for electromagnetic interference suppression and connection to the supply mains

(IEC 60384-14:2023)

Insulation coordination for equipment within low-voltage systems — Part 1:

EN IEC 60664-1:2020,

Principles, requirements and tests (IEC 60664-1:2020)

As impacted by EN 60034-8:2007/A1:2014.

As impacted by EN 60332-1-2:2004/A1:2015, EN 60332-1-2:2004/A11:2016 and EN 60332-1-

2:2004/A12:2020.

As impacted by EN 60529:1991/A1:2000, EN 60529:1991/A2:2013, EN 60529:1991/AC:2019-02,

EN 60529:1991/AC:2016-12 and EN 60529:1991/A2:2013/AC:2019-02.

As impacted by EN 60695-11-10:2013/AC:2014.

As impacted by EN 60947-5-5:1997/A1:2005, EN 60947-5-5:1997/A11:2013 and EN 60947-5-

5:1997/A2:2017.

As impacted by EN 61643-11:2012/A11:2018.

As impacted by EN 62620:2015/A1:2023.

As impacted by EN IEC 60664-1:2020/AC:2020-12.

EN IEC 62281:2019, Safety of primary and secondary lithium cells and batteries during transport (IEC

62281:2019)

EN IEC 62619:2022, Secondary cells and batteries containing alkaline or other non-acid electrolytes —

Safety requirements for secondary lithium cells and batteries, for use in industrial applications (IEC

62619:2022)

EN IEC 62902:2019, Secondary batteries — Marking symbols for identification of their chemistry (IEC

62902:2019)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13849-1:2023, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2023)

EN ISO 3691-1:2015, Industrial trucks — Safety requirements and verification — Part 1: Self-propelled

industrial trucks, other than driverless trucks, variable-reach trucks and burden-carrier trucks (ISO

3691-1:2011, including Cor 1:2013)

EN ISO 3691-2:2023, Industrial trucks — Safety requirements and verification — Part 2: Self-propelled

variable-reach trucks (ISO 3691-2:2023)

Industrial trucks — Safety requirements and verification — Part 3: Additional

EN ISO 3691-3:2016,

requirements for trucks with elevating operator position and trucks specifically designed to travel with

elevated loads (ISO 3691-3:2016)

EN ISO 3691-6:2021, Industrial trucks — Safety requirements and verification — Part 6: Burden and

personnel carriers (ISO 3691-6:2021)

EN ISO 6743-4:2015, Lubricants, industrial oils and related products (class L) — Classification — Part 4:

Family H (Hydraulic systems) (ISO 6743 4:2015)

IEC 60417:2024, DB, Graphical symbols for use on equipment

IEC 60947-4-1:2023, Low-voltage switchgear and controlgear — Part 4-1: Contactors and motor-starters

— Electromechanical contactors and motor-starters

ISO 3287:1999, Powered industrial trucks — Symbols for operator controls and other displays

ISO 5053-1:2020, Industrial trucks — Vocabulary — Part 1: Types of industrial trucks

ISO 7000:2019, Graphical symbols for use on equipment — Registered symbols

As impacted by EN IEC 62281:2019/A1:2021 and EN IEC 62281:2019/A2:2023.

As impacted by EN ISO 3691-1:2015/A1:2020.

As impacted by EN ISO 3691-3:2016/A1:2023.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 5053-1:2020 and the following

apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

U

n

nominal voltage of the truck system

designated value of the voltage of the electrical system and to which its characteristics are referred

3.2

nominal battery voltage

number of battery cells connected in series multiplied by the nominal cell voltage, relative to the chemical

technology of the cell

Note 1 to entry: If the battery consists of cells connected in series and in parallel, the nominal voltage is defined

by the number of cells, which are arranged in one line of cells connected in series.

3.3

drive system

electrically controlled system moving truck on ground, generating torque with effect on one or more

drive wheels

3.4

low speed

travel speed below 0,4 m/s for pedestrian trucks and below 0,7 m/s for all other types of trucks

3.5

LHS

electrical load handling system

system for electrical or electronically controlled load handling

3.6

electrical steering

electrical or electronic system controlling the angular position of the wheel(s) of the truck with respect

to its vertical longitudinal centre plane

Note 1 to entry: See Annex F for examples.

3.7

assistance system

system intended to improve the operational performance, the ergonomics of industrial trucks, or to warn

the operator about hazards due to improper use in the specific operation related to the work environment

and application

Note 1 to entry: Assistance systems are not necessary for the safe operation of industrial trucks and cannot be

used as safety functions (3.13).

3.8

PL

r

required performance level

performance level (PL) applied to achieve the required risk reduction for each safety function

[SOURCE: EN ISO 13849-1:2023, 3.1.6, note 1 to entry deleted]

3.9

setpoint

operator's physical actions on the intended control device

Note 1 to entry: For travelling, the actuation of the accelerator control.

3.10

actpoint

actual physical value of the system output

Note 1 to entry: Examples of actpoint are: truck speed, position of truck steered wheel(s), energised solenoid and

the combination of voltage, current and frequency applied to a drive motor.

3.11

service brake

braking system allowing the operator to control, directly or indirectly, the speed of the truck or to bring

the truck to a halt

[SOURCE: ISO 6292:2020, 3.9, modified by substituting “braking system” with “brake” in the term]

Note 1 to entry: The service brake can also be activated by the electronic control system of the truck.

Note 2 to entry: The service brake can also serve as a parking brake.

3.12

parking brake

braking system allowing a vehicle to be held stationary mechanically, even on an inclined surface,

particularly in the absence of the operator

[SOURCE: ISO 6292:2020, 3.8, modified by substituting “braking system” with “brake” in the term]

3.13

safety function

function of the machine whose failure can result in an immediate increase of the risk(s)

[SOURCE: EN ISO 12100:2010, 3.30]

3.14

risk

combination of the probability of occurrence of harm and the severity of that harm

[SOURCE: EN ISO 12100:2010, 3.12]

3.15

type test

test to the requirements of this document of an example of devices, systems or complete trucks

representative of the production, including the relevant range of options provided by the manufacturer

of the truck, as part of the verification of compliance with this document

3.16

routine test

tests carried out during series production necessary to maintain compliance with this document

3.17

control circuit

electrical circuit used for the control, including monitoring, of the truck and its electrical equipment

3.18

auxiliary circuit

electrical circuit that controls lights, fans and other accessories

3.19

power circuit

circuit that supplies power from the energy source to units of equipment used for truck operation

3.20

energy source

unit for energizing equipment of the truck used for productive operation

Note 1 to entry: Energy sources for trucks can be:

— batteries based on different technologies;

— liquid or gaseous fuel combined with internal combustion engine or fuel cell;

— AC power sources.

3.21

frame fault

accidental connection of a live part to the truck frame or exposed conductive parts

3.22

IC truck

truck equipped with an internal combustion engine of which the power is transferred to a mechanical,

hydraulic or electrical system

3.23

normal operating position

position in which the operator is able to control all functions for driving and load handling as defined by

the manufacturer

Note 1 to entry: Additional positions are permitted to be defined by the manufacturer if it is not possible to

control all the functions of the truck from a single position. A rotating seat or stand-up end-control truck with more

than one operating direction is considered as being or having a single operating position.

[SOURCE: EN ISO 3691-1:2015, 3.8]

3.24

high voltage truck

truck whose U is greater than 120 V DC or 50 V AC and less than or equal to 1 500 V DC or 1 000 V AC

n

under idle or fully charged condition

3.25

OPC

operator-presence control

device that detects the presence of the operator in the normal operating position

3.26

electric powered assisted steering system

mechanical and/or hydraulic steering system powered by an electrical system

4 Requirements

4.1 Introduction

Trucks shall comply with the safety requirements and/or protective measures of this clause. In addition,

the truck shall be designed according to the principles of EN ISO 12100:2010 for relevant but not

significant hazards which are not dealt with by this document.

4.2 Validation of safety functions

The design of safety functions shall be validated in accordance with EN ISO 13849-1:2023, Clause 10.

4.3 General requirements

4.3.1 Low voltage/high voltage

Nominal voltage of the truck system shall not exceed 1 500 V DC or 1 000 V AC.

Safety shall not be compromised at any voltage level that can occur.

Electrical systems of trucks powered by lead-acid batteries shall be designed so that all functions operate

in the voltage range from 70 % up to 120 % of the nominal battery voltage. These limits shall be adapted

to other energy sources technologies.

NOTE Limits set by the manufacturer for other energy sources are outside the scope of this document.

4.3.2 Frame fault

The electric circuits shall be so designed or protected, that frame faults shall not cause hazardous

inadvertent movements that cannot be corrected or compensated by the operator. Compliance shall be

verified by means of the type test of 4.9.7.

4.3.3 Protection from ingress of water and dust

The electrical installation of the trucks in operating condition shall be designed and constructed such that

the protection from harmful ingress of water and dust is in accordance with the environmental conditions

in which the truck is designed to operate, including reasonably foreseeable misuses, as defined in the

instruction handbook (for example, EN ISO 3691-1:2015, 6.2.2).

NOTE Standardized degrees of protection provided by the enclosure of the electrical equipment are given in

EN 60529:1991.

4.3.4 Protection against electric shock

Non-insulated live parts of trucks in the operating condition shall be protected to a degree of IPXXB

preventing direct contact. For top surfaces, the minimum degree shall be IPXXD in accordance with

EN 60529:1991.

Access to an electrical enclosure containing uninsulated live parts in excess of nominal voltage 60 V DC

or 25 V AC shall be possible only using a tool.

Indirect contact with live parts shall be avoided by electric separation of the protection devices in

accordance with EN 60204-1:2018, 6.3.2.3.

It shall be possible to electrically disconnect the energy sources for maintenance and replacement

operations. An easily accessible switch, connector or disconnectable battery terminals meets the intent

of this requirement.

For energy sources with nominal voltage greater than 60 V DC or 25 V AC live parts shall be protected

against direct contact.

4.3.5 Connection to the frame

4.3.5.1 Battery powered trucks

There shall be no electrical connection to the truck frame, except for:

a) frame fault detection system;

b) electric/electronic circuits with a nominal voltage not greater than 60 V DC which are galvanically

separated from the energy source;

c) connection to the earthing terminal of on-board chargers;

d) suppression capacitors. Where the nominal battery voltage exceeds 60 V DC, minimum requirement

for the capacitor shall be Class Y in accordance with EN IEC 60384-14:2023;

e) the screen of shielded cables and components. This condition shall meet the requirements of the

insulation resistance testing in 4.9.5;

f) suppression resistor for electrostatic discharge reduction, the system shall meet the requirements of

4.9.5.

4.3.5.2 IC trucks

a) Electrical system with nominal voltage not greater than 48 V (starter battery):

— all conductors of the electrical system not connected to the truck frame shall be effectively

insulated. They shall be protected against thermal and mechanical damage where such damage

is expected;

— there shall be means to disconnect both poles of the starter battery from the truck for service

purposes.

NOTE A connection of the electrical system to the truck frame is not excluded.

b) Electrical system with nominal voltage greater than 48 V (hybrid drive system):

— electrical systems with nominal voltage greater than 48 V shall be electrically insulated and

galvanically separated from frame, with the exceptions listed in 4.3.5.1 a), b), d), e) and f);

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...