prEN 593

(Main)Industrial valves - Metallic butterfly valves

Industrial valves - Metallic butterfly valves

This European Standard specifies minimum general requirements for butterfly valves having metallic bodies for use with all type of pipe end connections (e.g. wafer, lug, flange, butt welding) and used for isolating, regulating or control applications.

The PN and Class ranges are:

- PN 2,5; PN 6; PN 10; PN 16; PN 25; PN 40; PN 63; PN 100; PN 160;

- Class 150; Class 300; Class 600; Class 900.

The size range is:

- DN 20; DN 25; DN 32; DN 40; DN 50; DN 65; DN 80; DN 100; DN 125; DN 150; DN 200; DN 250; DN 300; DN 350; DN 400; DN 450; DN 500; DN 600; DN 700; DN 750; DN 800; DN 900; DN 1 000; DN 1 050; DN 1 100; DN 1 200; DN 1 400; DN 1 500; DN 1 600; DN 1 800; DN 2 000; DN 2 200; DN 2 400; DN 2 600; DN 2 800; DN 3 000; DN 3 200; DN 3 400; DN 3 600; DN 3 800; DN 4 000.

DN 750 and DN 1 050 are used only for Class 150 and Class 300.

Intermediate DNs are allowed upon agreement between manufacturer and customer.

For valves subject to European legislation on pressure equipment, EN 16668 applies together with this European Standard.

For industrial process control valves, EN 1349 and EN 60534 2 1 apply together with this European Standard.

For water supply application, EN 1074 1 and EN 1074 2 apply together with this European Standard.

NOTE 1 Butterfly valves for water supply application do not comply with Annex ZA and are not CE marked because they are excluded from the pressure equipment European legislation.

NOTE 2 The range of DN, applicable to each PN, for wafer and wafer lug valve types is as given in the appropriate part of EN 1092 for Type 11 flanges for the applicable material. The range of DN, applicable to each PN, for flanged valve types is as given in the appropriate part of EN 1092 for Type 21 flanges for the applicable material.

The correspondence between DN and NPS is given for information in Annex D.

Industriearmaturen - Metallische Klappen

Dieses Dokument legt allgemeine Mindestanforderungen an Klappen mit metallischem Gehäuse fest, die für den Einbau in alle Typen von Rohrendverbindungen (Scheiben, Ösen, Flanschen, Anschweißenden) bestimmt sind und zum Absperren, Stellen oder Regeln benutzt werden.

Der PN- und Classbereich umfasst:

PN 2,5; PN 6; PN 10; PN 16; PN 25; PN 40; PN 63; PN 100; PN 160;

Class 150; Class 300; Class 600; Class 900.

Der Größenbereich umfasst:

DN 20; DN 25; DN 32; DN 40; DN 50; DN 65; DN 80; DN 100; DN 125; DN 150; DN 200; DN 250; DN 300; DN 350; DN 400; DN 450; DN 500; DN 600; DN 700; DN 750; DN 800; DN 900; DN 1 000; DN 1 050; DN 1 100; DN 1 200; DN 1 400; DN 1 500; DN 1 600; DN 1 800; DN 2 000; DN 2 200; DN 2 400; DN 2 600; DN 2 800; DN 3 000; DN 3 200; DN 3 400; DN 3 600; DN 3 800; DN 4 000.

DN 750 und DN 1 050 werden nur für Class 150 und Class 300 verwendet.

Zwischen-Nennweiten sind zulässig bei Vereinbarung zwischen Hersteller und Kunde.

Dieses Dokument gilt für Klappen aus Metall, die für alle industriellen Anwendungsfälle verwendet werden. Zusätzliche Anforderungen der jeweiligen Anwendungsnormen können für Klappen gelten, die für spezifischere Anwendungen verwendet werden (z. B. Wasserwirtschaft, chemische und petrochemische Verfahrensindustrie, Gasverteilung).

ANMERKUNG 1 Industrielle Anwendungsfälle schließen Anwendungen in der Wasserversorgung mit ein.

Für Armaturen gemäß der Europäischen Gesetzgebung gilt EN 16668 zusammen mit diesem Dokument.

Für Regelarmaturen für die Prozessregelung gelten EN 1349 und EN 60534 2 1 zusammen mit diesem Dokument.

Bei Anwendungen in der Wasserversorgung gelten EN 1074 1 und EN 1074 2 zusammen mit diesem Dokument.

ANMERKUNG 2 Klappen für die Anwendung in der Wasserversorgung entsprechen nicht Anhang ZA und haben keine CE-Kennzeichnung, weil sie von der Europäischen Richtlinie über Druckgeräte ausgeschlossen sind.

ANMERKUNG 3 Der Nennweitenbereich für Einklemmklappen und Klappen mit Flanschaugen, der auf jede PN anwendbar ist, wird im entsprechenden Teil der EN 1092 für Flansche des Typs 11 für den anzuwendenden Werkstoff angegeben. Der Nennweitenbereich für Klappen mit Flansch, der auf jede PN anwendbar ist, wird im entsprechenden Teil der EN 1092 für Flansche des Typs 21 für den anzuwendenden Werkstoff angegeben.

Die Zuordnung zwischen DN und NPS ist als Information in Anhang D angegeben.

Robinetterie industrielle - Robinets métalliques à papillon

Le présent document spécifie les exigences minimales générales relatives aux robinets à papillon à corps métallique destinés à être utilisés avec tous les types de raccordements d’extrémités de tuyauterie (par exemple à insérer, à oreilles, à brides, à souder en bout) et utilisés pour des applications de sectionnement, réglage ou régulation.

Les gammes de PN et de Class sont:

PN 2,5; PN 6; PN 10; PN 16; PN 25; PN 40; PN 63; PN 100; PN 160;

Class 150; Class 300; Class 600; Class 900.

La gamme de dimension est:

DN 20; DN 25; DN 32; DN 40; DN 50; DN 65; DN 80; DN 100; DN 125; DN 150; DN 200; DN 250; DN 300; DN 350; DN 400; DN 450; DN 500; DN 600; DN 700; DN 750; DN 800; DN 900; DN 1 000; DN 1 100; DN 1 200; DN 1 400; DN 1 500; DN 1 600; DN 1 800; DN 2 000; DN 2 200; DN 2 400; DN 2 600; DN 2 800; DN 3 000; DN 3 200; DN 3 400; DN 3 600; DN 3 800; DN 4 000.

Le DN 750 et le DN 1 050 sont utilisés uniquement pour les Class 150 et Class 300.

Des DNs intermédiaires sont autorisés soumis à accord entre fabricant et client.

Le présent document s'applique aux robinets métalliques à papillon utilisés dans toutes les applications industrielles. Des exigences supplémentaires données dans les normes d'application pertinentes peuvent s'appliquer aux robinets à papillon utilisés dans des applications plus spécifiques (par exemple dans le secteur de l'eau, dans l'industrie de procédés chimiques et pétrochimiques, dans l'industrie de distribution du gaz).

NOTE 1 Les applications industrielles couvre les applications pour l'eau.

Pour les appareils de robinetterie soumis à la règlementation européenne sur les équipements sous pression, l’EN 16668 s'applique en complément du présent document.

Pour les robinets de régulation des processus industriels, voir l’EN 1349 et l’EN 60534-2-1 qui s'appliquent en complément du présent document.

Pour les applications d'approvisionnement en eau, l'EN 1074-1 et l'EN 1074-2 s'appliquent en complément du présent document.

NOTE 2 Les robinets à papillon pour des applications d'approvisionnement en eau ne respectent pas l'Annexe ZA et ne sont pas marqués CE parce qu'ils sont exclus de la règlementation européenne sur les équipements sous pression.

NOTE 3 La gamme de DN, applicable à chaque PN, pour les types d'appareil de robinetterie à insérer et à oreilles, est telle que donnée dans la partie appropriée de l'EN 1092 pour les brides de type 11 pour le matériau approprié. La gamme de DN, applicable à chaque PN, pour les types d'appareil de robinetterie à brides, est telle que donnée dans la partie appropriée de l'EN 1092 pour les brides de type 21 pour le matériau approprié.

La correspondance entre DN et NPS est fournie pour information en Annexe D.

Industrijski ventili - Kovinske zaporne lopute

General Information

- Status

- Not Published

- Publication Date

- 16-May-2021

- Withdrawal Date

- 16-Nov-2021

- Technical Committee

- CEN/TC 69 - Industrial valves

- Drafting Committee

- CEN/TC 69/WG 4 - Butterfly valves

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Start Date

- 09-Nov-2020

- Completion Date

- 28-Jan-2026

Relations

- Effective Date

- 28-Nov-2018

Overview

The European Standard prEN 593 specifies the minimum general requirements for metallic butterfly valves used in industrial applications. Developed by CEN/TC 69, this draft standard applies to butterfly valves with metallic bodies designed for various pipe end connections such as wafer, lug, flange, and butt welding. The valves covered are intended for isolating, regulating, or control applications across industries.

With a wide pressure nominal (PN) range from 2.5 to 160 and Class ratings from 150 to 900, prEN 593 supports an extensive valve size range from DN 20 up to DN 4000. The standard ensures compatibility and safety in compliance with European legislation on pressure equipment, integrating additional requirements from relevant application-specific standards.

Key Topics

Scope and Applicability

prEN 593 covers metallic butterfly valves used in all industrial sectors, including water supply, chemical, petrochemical, and gas distribution industries. It sets requirements for valves subject to pressure equipment legislation (Directive 2014/68/EU) and supports related standards such as EN 16668 for pressure equipment, EN 1349 and EN 60534-2-1 for process control valves, and EN 1074-1/2 for water supply.Pressure and Size Ranges

- PN Ratings: 2.5 to 160

- Class Ratings: 150, 300, 600, 900

- Size Range: DN 20 to DN 4000 (with specific DN ranges applicable for certain classes)

Intermediate nominal diameters can be negotiated between manufacturer and customer for specialized needs.

Design Requirements

prEN 593 details design criteria such as valve shell and body construction, obturator (disc) and seat seal quality, driving shaft and shaft seal accuracy, corrosion protection, and pressure/temperature ratings. Specific attention is given to face-to-face and end-to-end valve dimensions to maintain interchangeability.Testing and Assessment

The standard lays out functional testing methods including shell tightness, seat tightness, and optional tests to ensure valve performance under specified conditions. It also specifies final assessment protocols aligned with European pressure equipment directives.Marking and Documentation

Clear requirements for valve marking, including mandatory and supplementary information, help ensure traceability and compliance. The documentation requirements provide transparency and support for storage and transportation procedures.

Applications

Metallic butterfly valves designed according to prEN 593 are suitable for diverse applications:

- Industrial process control in chemical plants, petrochemical refineries, and manufacturing facilities.

- Water supply systems, supporting flow regulation and isolation, although valves for this purpose do not require CE marking as they fall outside of pressure equipment legislation.

- Oil and gas distribution, ensuring safe control of high-pressure pipelines.

- Power generation plants, enabling reliable isolation and flow control of steam, gas, and water systems.

- HVAC systems and other building infrastructure applications requiring robust valve solutions.

By adhering to prEN 593, manufacturers and end-users can ensure valves meet stringent European and international standards for quality, safety, and performance.

Related Standards

prEN 593 works in conjunction with several other key European standards to provide a comprehensive regulatory framework for industrial butterfly valves:

- EN 16668 – Requirements for pressure equipment, complementing safety and legislative compliance.

- EN 1349 & EN 60534-2-1 – Standards focusing on industrial process control valves and their functional performance.

- EN 1074-1 and EN 1074-2 – Specific to water supply isolating valves, detailing fitness for purpose and verification tests.

- EN 1092 series – Covering flange dimensions and connections compatible with valve end connections.

- EN 558 – Detailing face-to-face and center-to-face dimensions of metal valves to ensure compatibility in piping systems.

- EN 19 – Guidelines for marking metallic industrial valves to support identification and traceability.

This synergy between standards ensures that metallic butterfly valves manufactured under prEN 593 meet both general and application-specific requirements across multiple European industries.

By complying with prEN 593, stakeholders gain assurance in valve design integrity, safety compliance, and operational reliability-key factors for optimizing industrial valve selection and usage in demanding environments.

Frequently Asked Questions

prEN 593 is a draft published by the European Committee for Standardization (CEN). Its full title is "Industrial valves - Metallic butterfly valves". This standard covers: This European Standard specifies minimum general requirements for butterfly valves having metallic bodies for use with all type of pipe end connections (e.g. wafer, lug, flange, butt welding) and used for isolating, regulating or control applications. The PN and Class ranges are: - PN 2,5; PN 6; PN 10; PN 16; PN 25; PN 40; PN 63; PN 100; PN 160; - Class 150; Class 300; Class 600; Class 900. The size range is: - DN 20; DN 25; DN 32; DN 40; DN 50; DN 65; DN 80; DN 100; DN 125; DN 150; DN 200; DN 250; DN 300; DN 350; DN 400; DN 450; DN 500; DN 600; DN 700; DN 750; DN 800; DN 900; DN 1 000; DN 1 050; DN 1 100; DN 1 200; DN 1 400; DN 1 500; DN 1 600; DN 1 800; DN 2 000; DN 2 200; DN 2 400; DN 2 600; DN 2 800; DN 3 000; DN 3 200; DN 3 400; DN 3 600; DN 3 800; DN 4 000. DN 750 and DN 1 050 are used only for Class 150 and Class 300. Intermediate DNs are allowed upon agreement between manufacturer and customer. For valves subject to European legislation on pressure equipment, EN 16668 applies together with this European Standard. For industrial process control valves, EN 1349 and EN 60534 2 1 apply together with this European Standard. For water supply application, EN 1074 1 and EN 1074 2 apply together with this European Standard. NOTE 1 Butterfly valves for water supply application do not comply with Annex ZA and are not CE marked because they are excluded from the pressure equipment European legislation. NOTE 2 The range of DN, applicable to each PN, for wafer and wafer lug valve types is as given in the appropriate part of EN 1092 for Type 11 flanges for the applicable material. The range of DN, applicable to each PN, for flanged valve types is as given in the appropriate part of EN 1092 for Type 21 flanges for the applicable material. The correspondence between DN and NPS is given for information in Annex D.

This European Standard specifies minimum general requirements for butterfly valves having metallic bodies for use with all type of pipe end connections (e.g. wafer, lug, flange, butt welding) and used for isolating, regulating or control applications. The PN and Class ranges are: - PN 2,5; PN 6; PN 10; PN 16; PN 25; PN 40; PN 63; PN 100; PN 160; - Class 150; Class 300; Class 600; Class 900. The size range is: - DN 20; DN 25; DN 32; DN 40; DN 50; DN 65; DN 80; DN 100; DN 125; DN 150; DN 200; DN 250; DN 300; DN 350; DN 400; DN 450; DN 500; DN 600; DN 700; DN 750; DN 800; DN 900; DN 1 000; DN 1 050; DN 1 100; DN 1 200; DN 1 400; DN 1 500; DN 1 600; DN 1 800; DN 2 000; DN 2 200; DN 2 400; DN 2 600; DN 2 800; DN 3 000; DN 3 200; DN 3 400; DN 3 600; DN 3 800; DN 4 000. DN 750 and DN 1 050 are used only for Class 150 and Class 300. Intermediate DNs are allowed upon agreement between manufacturer and customer. For valves subject to European legislation on pressure equipment, EN 16668 applies together with this European Standard. For industrial process control valves, EN 1349 and EN 60534 2 1 apply together with this European Standard. For water supply application, EN 1074 1 and EN 1074 2 apply together with this European Standard. NOTE 1 Butterfly valves for water supply application do not comply with Annex ZA and are not CE marked because they are excluded from the pressure equipment European legislation. NOTE 2 The range of DN, applicable to each PN, for wafer and wafer lug valve types is as given in the appropriate part of EN 1092 for Type 11 flanges for the applicable material. The range of DN, applicable to each PN, for flanged valve types is as given in the appropriate part of EN 1092 for Type 21 flanges for the applicable material. The correspondence between DN and NPS is given for information in Annex D.

prEN 593 has the following relationships with other standards: It is inter standard links to EN 593:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 593 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 593 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2020

Industrijski ventili - Kovinske zaporne lopute

Industrial valves - Metallic butterfly valves

Industriearmaturen - Metallische Klappen

Robinetterie industrielle - Robinets métalliques à papillon

Ta slovenski standard je istoveten z: prEN 593

ICS:

23.060.30 Zapirni ventili (zasuni) Gate valves

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

October 2019

ICS Will supersede EN 593:2017

English Version

Industrial valves - Metallic butterfly valves

Robinetterie industrielle - Robinets métalliques à Industriearmaturen - Metallische Klappen

papillon

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 69.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 593:2019 E

worldwide for CEN national Members.

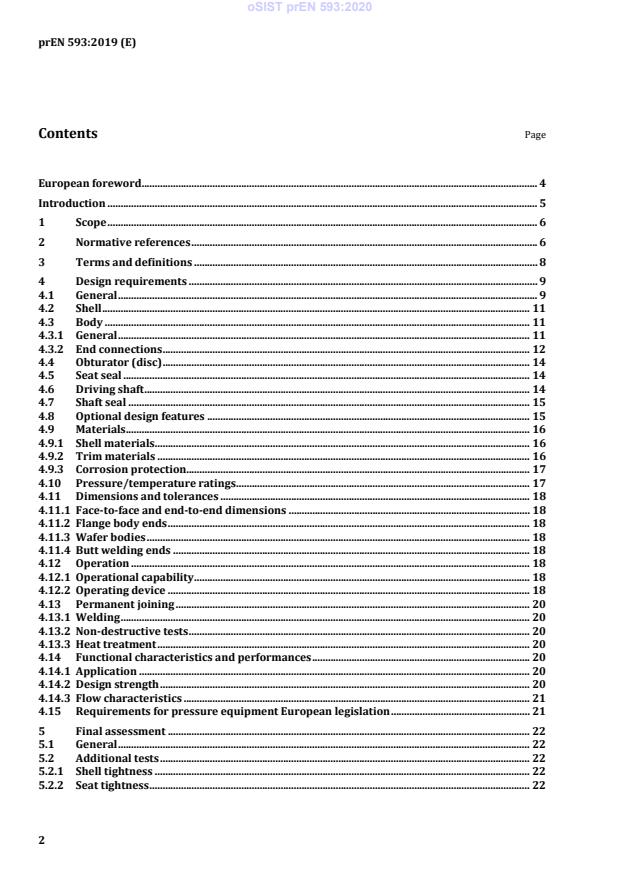

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

4 Design requirements . 9

4.1 General . 9

4.2 Shell . 11

4.3 Body . 11

4.3.1 General . 11

4.3.2 End connections . 12

4.4 Obturator (disc) . 14

4.5 Seat seal . 14

4.6 Driving shaft . 14

4.7 Shaft seal . 15

4.8 Optional design features . 15

4.9 Materials . 16

4.9.1 Shell materials . 16

4.9.2 Trim materials . 16

4.9.3 Corrosion protection. 17

4.10 Pressure/temperature ratings . 17

4.11 Dimensions and tolerances . 18

4.11.1 Face-to-face and end-to-end dimensions . 18

4.11.2 Flange body ends . 18

4.11.3 Wafer bodies . 18

4.11.4 Butt welding ends . 18

4.12 Operation . 18

4.12.1 Operational capability . 18

4.12.2 Operating device . 18

4.13 Permanent joining . 20

4.13.1 Welding . 20

4.13.2 Non-destructive tests . 20

4.13.3 Heat treatment . 20

4.14 Functional characteristics and performances . 20

4.14.1 Application . 20

4.14.2 Design strength . 20

4.14.3 Flow characteristics . 21

4.15 Requirements for pressure equipment European legislation . 21

5 Final assessment . 22

5.1 General . 22

5.2 Additional tests . 22

5.2.1 Shell tightness . 22

5.2.2 Seat tightness . 22

5.2.3 Optional tests . 23

5.3 Final assessment for pressure equipment European legislation . 23

6 Designation . 23

7 Marking and preparation for storage and transportation . 23

7.1 Marking . 23

7.1.1 Mandatory marking . 23

7.1.2 Supplementary marking . 23

7.2 Preparation for storage and transportation . 24

8 Documentation . 24

8.1 General . 24

8.2 Documentation for pressure equipment European legislation . 24

Annex A (informative) Information to be supplied by the customer . 25

Annex B (informative) Trim material list . 27

Annex C (informative) Environmental corrosion protection . 28

Annex D (informative) Correspondence between DN and NPS . 29

Annex E (informative) Example for valve shaft calculation . 30

E.1 General . 30

E.2 Calculation. 31

E.2.1 Shear stress . 31

E.2.2 Combined shear stress (at valve bearing) (section 2-2). 31

E.2.3 Combined tensile stress at seating due to torsion and bending (section 2-2) . 31

E.2.4 Shear stress at reduced area (sections 1-1, 3-3, 4-4) . 32

E.3 Examples of influence of flow velocity/hydrodynamic torques for shaft sizing . 32

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2014/68/EU (Pressure Equipment Directive) aimed to be

covered . 35

Bibliography . 37

European foreword

This document (prEN 593:2019) has been prepared by Technical Committee CEN/TC 69 “Industrial

valves”, the secretariat of which is held by AFNOR.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 593:2017.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive 2014/68/EU.

For relationship with EU Directive, see informative Annex ZA, which is an integral part of this document.

The main technical changes compared to the previous edition are:

a) inclusion of an introduction to explain the reason of this revision;

b) the inclusion of a sentence in the scope to clarify that this document applies to all industrial

applications;

c) addition of new 4.15 and 5.3 on the design requirements and final assessment for pressure

equipment European legislation;

d) addition of a new Clause 8 for the documentation;

e) update of Annex ZA.

Introduction

This document was revised to refer to EN 16668:2016+A1:2018 for all requirements related to pressure

equipment European legislation.

Annex ZA of this document is identical to Annex ZA of EN 16668:2016+A1:2018, for those requirements

applicable to butterfly valves.

1 Scope

This document specifies minimum general requirements for butterfly valves having metallic bodies for

use with all type of pipe end connections (e.g. wafer, lug, flange, butt welding) and used for isolating,

regulating or control applications.

The PN and Class ranges are:

— PN 2,5; PN 6; PN 10; PN 16; PN 25; PN 40; PN 63; PN 100; PN 160;

— Class 150; Class 300; Class 600; Class 900.

The size range is:

— DN 20; DN 25; DN 32; DN 40; DN 50; DN 65; DN 80; DN 100; DN 125; DN 150; DN 200; DN 250;

DN 300; DN 350; DN 400; DN 450; DN 500; DN 600; DN 700; DN 750; DN 800; DN 900; DN 1 000;

DN 1 050; DN 1 100; DN 1 200; DN 1 400; DN 1 500; DN 1 600; DN 1 800; DN 2 000; DN 2 200;

DN 2 400; DN 2 600; DN 2 800; DN 3 000; DN 3 200; DN 3 400; DN 3 600; DN 3 800; DN 4 000.

DN 750 and DN 1 050 are used only for Class 150 and Class 300.

Intermediate DNs are allowed upon agreement between manufacturer and customer.

This document applies to metallic butterfly valves used for all industrial applications. Additional

requirements given in the relevant application standards may apply to butterfly valves used for more

specific applications (e.g. for the water industry, the chemical and petrochemical process industry, the

gas distribution industry).

NOTE 1 Industrial applications cover water applications.

For valves subject to European legislation on pressure equipment, EN 16668 applies together with this

document.

For industrial process control valves, EN 1349 and EN 60534-2-1 apply together with this document.

For water supply application, EN 1074-1 and EN 1074-2 apply together with this document.

NOTE 2 Butterfly valves for water supply application do not comply with Annex ZA and are not CE marked

because they are excluded from the pressure equipment European legislation.

NOTE 3 The range of DN, applicable to each PN, for wafer and wafer lug valve types is as given in the appropriate

part of EN 1092 for Type 11 flanges for the applicable material. The range of DN, applicable to each PN, for flanged

valve types is as given in the appropriate part of EN 1092 for Type 21 flanges for the applicable material.

The correspondence between DN and NPS is given for information in Annex D.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 19:2016, Industrial valves - Marking of metallic valves

EN 558:2017, Industrial valves - Face-to-face and centre-to-face dimensions of metal valves for use in

flanged pipe systems - PN and Class designated valves

EN 736-1:2018, Valves - Terminology - Part 1: Definition of types of valves

EN 736-2:2016, Valves - Terminology - Part 2: Definition of components of valves

EN 736-3:2008, Valves - Terminology - Part 3: Definition of terms

EN 1074-2:2000, Valves for water supply - Fitness for purpose requirements and appropriate verification

tests - Part 2: Isolating valves

EN 1092-1:2018, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 1: Steel flanges

EN 1092-2:1997, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 2: Cast iron flanges

EN 1092-3:2003, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 3: Copper alloy flanges

EN 1092-4:2002, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 4: Aluminium alloy flanges

EN 1267:2012, Industrial valves - Test of flow resistance using water as test fluid

EN 1759-1:2004, Flanges and their joint - Circular flanges for pipes, valves, fittings and accessories, Class

designated - Part 1: Steel flanges, NPS 1/2 to 24

EN 1759-3:2003, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, Class

designated - Part 3: Copper alloy flanges

EN 1759-4:2003, Flanges and their joint - Circular flanges for pipes, valves, fittings and accessories, class

designated - Part 4: Aluminium alloy flanges

EN 10269:2013, Steels and nickel alloys for fasteners with specified elevated and/or low temperature

properties

EN 12266-1:2012, Industrial valves - Testing of metallic valves - Part 1: Pressure tests, test procedures and

acceptance criteria - Mandatory requirements

EN 12266-2:2012, Industrial valves - Testing of metallic valves - Part 2: Tests, test procedures and

acceptance criteria - Supplementary requirements

EN 12516-1:2014+A1:2018, Industrial valves - Shell design strength - Part 1: Tabulation method for steel

valve shells

EN 12516-2:2014, Industrial valves - Shell design strength - Part 2: Calculation method for steel valve shells

EN 12516-3:2002, Valves - Shell design strength - Part 3: Experimental method

EN 12516-4:2014+A1:2018, Industrial valves — Shell design strength — Part 4: Calculation method for

valve shells manufactured in metallic materials other than steel

EN 12570:2000, Industrial valves - Method for sizing the operating element

EN 12627:2017, Industrial valves — Butt welding ends for steel valves

EN 12982:2009, Industrial valves - End-to-end and centre-to-end dimensions for butt welding end valves

EN 16668:2016+A1:2018, Industrial valves - Requirements and testing for metallic valves as pressure

accessories

EN 60534-2-3:2016, Industrial-process control valves - Part 2-3: Flow capacity - Test procedures

EN ISO 1043-1:2011, Plastics - Symbols and abbreviated terms - Part 1: Basic polymers and their special

characteristics (ISO 1043-1:2011)

EN ISO 5211:2017, Industrial valves - Part-turn actuator attachments (ISO 5211:2017)

EN ISO 9606-1:2017, Qualification testing of welders - Fusion welding - Part 1: Steels (ISO 9606-1:2012

including Cor 1:2012 and Cor 2:2013)

EN ISO 10497:2010, Testing of valves - Fire type-testing requirements (ISO 10497:2010)

EN ISO 14732:2013, Welding personnel - Qualification testing of welding operators and weld setters for

mechanized and automatic welding of metallic materials (ISO 14732:2013)

EN ISO 15607:2003, Specification and qualification of welding procedures for metallic materials - General

rules (ISO 15607:2003)

ISO 1629:2013, Rubber and latices — Nomenclature

3 Terms and definitions

For the purposes of this document the terms and definitions given in EN 736-1, EN 736-2, EN 736-3,

EN 16668 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1

maximum allowable pressure

PS

maximum pressure for which the pressure equipment is designed as specified by the manufacturer

[SOURCE: EN 764-1:2015+A1:2016, 3.2.87]

3.2

maximum allowable temperature

TS

max

maximum temperature for which the pressure equipment is designed as specified by the manufacturer

[SOURCE: EN 764-1:2015+A1:2016, 3.1.9]

3.3

end of line service

condition that occurs when the downstream side of the valve is opened to atmosphere

3.4

driving shaft

shaft connected to the obturator to operate the valve in the case of a multi-shaft valve

3.5

trim

parts in contact with the fluid

3.6

eccentration

offset

deviation of the operating axes in respect to the reference axes of the pipe/valve

4 Design requirements

4.1 General

The valve shall be of either concentric design (see Figure 1) or eccentric design (see Figures 2 to 4). The

offset may be single, double or triple.

A first offset is an axial offset of the shaft to the seat contact.

A second offset is an offset from the pipe centreline to the valve obturator centerline.

In the triple offset design, the seat and seal contact surface centreline is inclined in respect to the pipe /

valve centreline, whatever the form of the contact.

Figure 1 — Concentric design

Key

e eccentricity 1

Figure 2 — Single eccentric design (single offset)

Key

e1 eccentricity 1

e eccentricity 2

Figure 3 — Double eccentric design (double offset)

Key

e eccentricity 1

e eccentricity 2

e3 eccentricity 3

Figure 4 — Triple eccentric design (triple offset)

The design details are the responsibility of the manufacturer.

The butterfly valve may be:

— soft sealing; or

— metallic sealing.

NOTE The choice of design and material depends on the design working temperature and the physical and

chemical characteristics of the fluid.

4.2 Shell

The shell is the combination of all pressure retaining part:

— the body,

— the retaining elements of the shaft seal ring or the stuffing box;

— the cover and the cover bolting if any,

— if used as end of line, the obturator and the shaft.

4.3 Body

4.3.1 General

Flanges of double flanged valves and single flange wafer valves shall have bolt holes in accordance with

the relevant standard as specified in 4.11.2. Threaded holes can be provided where the design of the valve

precludes through flange bolting.

Flangeless wafer valves (see Figure 6) are intended for clamping between pipe flanges using through

bolting. The shape of wafer valve bodies shall be such that centring of the valves within the appropriate

flange bolt circle is ensured. Where through bolting is not practicable due to the valve design, e.g. close

to shaft passages, threaded holes can be provided for individual bolting.

Lugged or single flange wafer valves (see Figure 7) are supplied with threaded or through holes for

installation between two flanged components or at the end of a pipeline (i.e. end of line service or

downstream dismantling).

Threaded holes shall allow full thread engagement to a depth at least equal to the nominal bolt diameter

and at least 0,67 of the bolt diameter when the bolt hole is adjacent to the valve shaft.

For Class designed valves threaded body flange holes for bolts 1 inch or less in diameter shall be drilled

and tapped in accordance with UNC coarse thread series, Class 2B (see ASME B1.1). For bolts 1 1/8 inches

or more in diameter, such holes shall be drilled and tapped in accordance with UN 8 thread series,

Class 2B (see ASME B1.1). Other threads shall be specified.

The manufacturer's literature shall be consulted to determine if through bolting or/and end of line

assembly is possible. Any limitation regarding end of line service condition shall be indicated.

Elastomeric or plastic linings and liners can be extended over the flange faces of the body to form a gasket

for the flange.

4.3.2 End connections

End connections shall be either one of the following.

a) Double flanged butterfly valve: butterfly valve having double flanged body ends for connection to

flanges of adjacent components by individual bolting (see Figure 5).

b) Wafer butterfly valve: butterfly valve intended for clamping between flanges of adjacent

components.

NOTE Different body shapes are possible: see Figures 6 and 7 a) to g).

c) Butt welding end butterfly valve: butterfly valve intended for butt welding into a pipeline

(see Figure 8).

d) Mechanical connection for loose flange connection: butterfly valve with one or both loose flanges for

compensation of piping alignment (see Figure 9). The loose flange shall be pullout proof.

e) Mechanical connection: butterfly valve with one or two interfaces for connection of piping

(see Figures 10 and 11). The connection shall be spigot end or socket end. Requirements and test

methods of mechanical joints are described in EN 545. The connection may be pullout proof.

Figure 5 — Double flanged body Figure 6 — Flangeless wafer body

a) Valve with central lugs b) Central single flange valve

c) Valve with lugs with internally threaded holes d) Single-flange valve with internally threaded

holes

e) Valve with lugs with drilled holes f) Single-flange valve with drilled holes

g) Valve with U-section

Figure 7 — Wafer valve bodies bolting configurations

Figure 8 — Butt welding end body

Figure 9 — Loose-flange design Figure 10 — Socket-socket Figure 11 — Spigot-socket

design design

4.4 Obturator (disc)

The obturator (often named disc) can be with or without seal.

The valve manufacturer's technical documentation shall specify all necessary dimensions showing the

protrusion of the obturator in the open position beyond the faces of the valve.

4.5 Seat seal

In its technical documentation, the valve manufacturer shall specify whether the seat seal

— is a body liner by design, or

— is located in the body or on the obturator.

The liner/lining may have additional functions, including sealing the driving shaft and flange.

The valve documentation shall specify the seat materials and if the sealing element is replaceable or not.

4.6 Driving shaft

The external end of the driving shaft shall indicate the orientation of the obturator.

The choice of the shaft material depends on the design working temperature and the physical and

chemical characteristics of the fluid.

Valve shafts shall be sized for the maximum design torque at seating operation and at obturator position

of highest combined dynamic and bearing torques with a safety factor. The value of this safety factor

depends on the calculation method of the driving shaft. An example of calculation method is given in

Annex E.

The connection between the shaft and the obturator shall be designed to transmit the shaft torque with

the same safety factor. Higher flow velocities than defined in Table 1 may cause higher dynamic torques

(see examples in Annex E).

The outside end of the shaft shall indicate by design or marking the position of the obturator. Where

required by the design of valve, the manufacturer's operating instructions shall specify the method to

preserve the indication of the obturator position, during and after re-assembly of the obturator to the

shaft, e.g. for routine maintenance.

The sealing of the shaft shall remain leak tight to atmosphere when the operating device is removed.

The shaft shall be retained in the valve, so it cannot be ejected out of the body when external parts are

removed. It shall be in accordance with EN 736-3.

External parts as stated in EN 736-3:2008, 3.3.7, are parts which are not included in the bare shaft valve

e.g. bracket, lever, actuator.

4.7 Shaft seal

The shaft seal tightness shall remain unchanged when the actuating device is removed.

The shaft seal is not part of the shell.

4.8 Optional design features

a) Fire type tested design: valves designated as fire type tested design shall be tested in accordance with

EN ISO 10497.

If valves are required to be a fire type tested design, this requirement shall be specified (see Annex A).

b) Anti-static design: valves with anti-static design shall have electrical continuity between shaft,

obturator and body in accordance with EN 12266-2.

If valves are required to be an anti-static design, this requirement shall be specified (see Annex A).

c) Valves may be designed with a blocking device of the shaft which fixes the open or close position for

maintenance purposes of the gearbox by an external blocking device. See Figure 12.

d) Valves may be designed with a blocking device which fixes the obturator in closed and tight position

independently of the function of the actuator. The blocking device acts as a safety device.

See Figure 13.

Key

1 external blocking device

Figure 12 — Blocking device of the shaft

Figure 13 — Blocking device of the obturator

4.9 Materials

4.9.1 Shell materials

Materials for the shell shall be selected from those described in EN 12516-1, EN 12516-2 and EN 12516-

4.

Bolting material shall be selected from EN 10269.

4.9.2 Trim materials

The trim comprises the following:

a) body or obturator seats;

b) shaft and seat seals;

c) shafts;

d) bushes;

e) shaft/obturator connecting parts;

f) seat/obturator seal clamping rings;

g) clamping ring bolting;

h) body lining/coating;

i) obturator linings/coatings.

The technical documentation of the valve manufacturer shall specify the relevant materials for the trim

parts (see Annex B).

The materials of seat and seal can be elastomeric, plastic, composite, graphite, metallic or a combination

of these materials.

The valve manufacturer's technical documentation shall specify the material type of the seat or liner or

seal.

4.9.3 Corrosion protection

The choice of materials and/or surface protection methods used shall be included in the manufacturer's

technical documentation and may be subject to agreement with the customer.

a) External corrosion protection: valve shells shall be protected against corrosion by proper material

selection or surface treatment.

Surface treatment system may be chosen according to classification category given by Annex C or

agreed between customer and manufacturer.

Test assessment and test procedures are the responsibility of the manufacturer.

b) Internal corrosion protection: all surfaces in contact with the fluid shall be protected against

corrosion by suitable material selection or surface treatment (see Annex B) or agreed between

customer and manufacturer.

4.10 Pressure/temperature ratings

The pressure/temperature rating shall be as specified in:

a) steel materials: EN 12516-1:2014+A1:2018 for the particular body/bonnet material group;

b) cast iron materials: EN 1092-2:1997;

c) copper alloy materials: EN 1092-3:2003 for PN-designated valves; EN 1759-3:2003 for Class-

designated flanged valves;

d) aluminium alloys: EN 1092-4:2002 for PN-designated valves; EN 1759-4:2003 for Class-designated

flanged valves.

Where restrictions on pressure and/or temperature are necessary on valves by reason of valve type, trim

materials or other factors, the maximum allowable pressure and/or temperature shall be marked on the

valve (in accordance with 7.1.2) and shall be considered with the designation of the valve [in accordance

with Clause 6 i)].

It is recommended that the service conditions under which a butterfly valve is to be used should be

specified by the customer (see Annex A).

4.11 Dimensions and tolerances

4.11.1 Face-to-face and end-to-end dimensions

The face-to-face dimensions and tolerances for flanged and wafer type butterfly valves shall be selected

from EN 558 for PN- and Class-designated valves.

The end-to-end dimensions and tolerances for butt welding end butterfly valves shall be selected from

EN 12982.

The face-to-face or end-to-end dimension for DN lower or larger than those defined in EN 558 or

EN 12982 shall be specified by the manufacturer.

For spigot and mechanical joint, the end-to-end dimensions may be according to the manufacturer's

technical documentation.

For loose flange connection, the end-to-end dimensions may be according to EN 558, series 14, but with

a higher length tolerance for pipe assembling.

4.11.2 Flange body ends

Flanged ends shall be in accordance with:

a) EN 1092-1, EN 1092-2, EN 1092-3 and EN 1092-4 for PN designated butterfly valves;

b) EN 1759-1, EN 1759-3 and EN 1759-4 for Class designated butterfly valves.

4.11.3 Wafer bodies

Flangeless, lugged or single flanged bodies shall be such that they can be clamped between flanges in

accordance with:

a) EN 1092-1, EN 1092-2, EN 1092-3 and EN 1092-4 for PN designated butterfly valves;

b) EN 1759-1, EN 1759-3 and EN 1759-4 for Class designated butterfly valves.

4.11.4 Butt welding ends

Butt welding end profiles shall be in accordance with EN 12627.

4.12 Operation

4.12.1 Operational capability

All butterfly valves shall be capable of being operated from fully closed to fully open, and vice-versa, at a

differential pressure across the obturator equal to the maximum allowable pressure, PS at 20 °C or as

marked on the valve, taking into account the limits in flow velocity (see Table 1).

4.12.2 Operating device

4.12.2.1 Direct manual actuation

Direct manual actuation may be lever, handwheel or T-wrench.

Where a lever is used, the valve shall be open when the lever is parallel to the pipe.

When intermediate position is specified, means of securing the valve obturator in intermediate positions

shall be provided.

4.12.2.2 Direct actuation by power actuator

The design of the valve shall allow, with or without an intermediate part, mounting of a pneumatic,

hydraulic or electric part-turn actuator complying with EN ISO 5211.

4.12.2.3 Gear actuation

The manual gear actuator shall be of self-locking movement design (in any position) and shall be provided

with stops in the two extreme travel positions.

Adjustable stop(s) shall be set and secured in a reliable way.

The gear actuator shall be fitted with a position indicator.

On request, the manufacturer shall supply the number of turns that are necessary to complete a full

opening or closing operation.

The design of the valve shall allow, with or without an intermediate part, mounting of a gear actuator

with a plate complying with EN ISO 5211.

4.12.2.4 Sizing the operating element

For any manual operation of valves, the minimum size of the operating element shall be in accordance

with EN 12570. The size of the operating element shall be selected such that the valve can be operated:

a) when the allowable differential pressure is equal to the maximum allowable pressure, and

b) taking into account the effect of hydrodynamic torque due to flow velocity.

When specified by the customer, it is allowed to size an actuator based on a reduced differential pressure

taking into account the effect of the hydraulic torque.

According to 7.1, the actual differential pressure shall be marked on the valve.

4.12.2.5 Direction of operation

Manually operated valves and bare shaft valves shall normally be closed by turning the handwheel or

lever or the shaft in a clockwise direction when facing the handwheel or lever or the shaft end.

If anti-clockwise closing is required, this shall be specified and marked on the operating element.

4.12.2.6 Valve supplied bare shaft

When, on request, a butterfly valve without an operating device is supplied, the manufacturer shall

provide:

a) the necessary torque value, based on the maximum flow velocities as specified in Table 1;

b) maximum allowable pressure, PS at 20 °C;

c) the maximum differential pressure marked on the valve;

d) direction of operation to close the valve;

e) shaft end dimensions according to EN ISO 5211 or other as required.

4.13 Permanent joining

4.13.1 Welding

Welding as part of the valve shell shall be carried out to approved welding procedures to EN ISO 15607

or other appropriate standard. Welders shall be approved to EN ISO 9606-1 and welding operators shall

be approved to EN ISO 14732 or other appropriate standard.

4.13.2 Non-destructive tests

If non-destructive test of welded joints, which are part of the valve shell, is required, it shall be detailed

in the approved welding procedure.

4.13.3 Heat treatment

Heat treatment requirements of welded joints, which are part of the valve shell, shall be detailed in the

approved welding procedure.

4.14 Functional characteristics and performances

4.14.1 Application

Butterfly valves intended for isolating applications require being seat tight in the closed position of the

obturator.

NOTE For appropriate seat leakage rate, see 5.2.2.

Butterfly valves intended for regulating or control applications may have a clearance between obturator

and body seat in the closed position.

The suitability of valves for end of line service shall be specified by the manufacturer either in the

technical documentation or on the valve (seat tightness and pressure).

4.14.2 Design strength

The shell strength resistance shall be

a) for steel valves designed by the tabulation method, according to EN 12516-1:2014+A1:2018,

b) for steel valves designed by calculation, according to EN 12516-2:2014,

c) for valves in metallic materials other than steel, according to EN 12516-4:2014+A1:2018,

d) if the shell strength resistance is validated by an experimental method, according to EN 12516-

3:2002.

Other dimensioning methods (i.e. finite elements) are the responsibility of the valve manufacturer.

The dimensioning procedures of parts using materials other than those specified in EN 12516-1,

EN 12516-2, EN 12516-3 or EN 12516-4 are the responsibility of the manufacturer.

Flange dimension for PN-designated valves according to EN 1092-1, EN 1092-2, EN 1092-3 and EN 1092-

4 shall not be recalculated.

Flange dimension for Class-designated valves according to EN 1759-1, EN 1759-3 and EN 1759-4 shall

not be recalculated.

The design of the other parts is determined for a differential pressure defined by the

pressure/temperature rating or for a differential pressure which shall be indicated on the valve.

4.14.3 Flow characteristics

4.14.3.1 Flow velocity

Butterfly valves shall be designed such that they are suitable for the maximum flow velocities specified

in Table 1 for the applicable PS of the valve design in fully open position. The velocity calculation refers

to the nominal size of the valve.

NOTE 1 Flow velocity is a design parameter to be considered for butterfly valves: see Annex E for examples.

NOTE 2 The flow velocity is the quotient of the volumetric flow rate (expressed in m /s) and the area calculated

using the diameter (expressed in m) having a value equal to the number of the DN divided by 1 000.

Table 1 — Flow velocity

PS Maximum flow velocity

bar m/s

Liquids with a density of Gas (at density 1,293 kg/m at 273 °K

3 a a

1 000 kg/m and 1 bara)

Up to 6 2,5 25

6 < PS ≤ 10 3 30

10 < PS ≤ 16 4 35

PS > 16 5 40

a

In case of other physical properties of fluids, the values are adapted to the specific weight of the fluid.

4.14.3.2 Flow coefficient K

v

The manufacturer shall provide the flow coefficient (K ) in the fully open position and the butterfly valve

v

characteristic curve shall define the variation of the flow coefficient depending on the valve opening.

Measurement of the flow resistance ζ of butterfly valves intended for isolating purpose shall be in

accordance with the procedure specified in EN 1267.

For valves intended for flow control only, the test of the flow resistance shall be in accordance with

EN 60534-2-3.

4.15 Requirements for pressure equipment European legislation

Valves subject to pressure equipment European legislation shall comply with the following:

a) for general design, the requirements of EN 16668:2016+A1:2018, 5.1.1;

b) for design loading factors, the requirements of EN 16668:2016+A1:2018, 5.1.2 a), 5.1.2 b),

5.1.2 c);

c) for design for adequate strength, the requirements of EN 16668:2016+A1:2018, 5.1.2 b), 5.1.2 c),

5.1.2 d);

d) for design calculation method, the requirements of EN 16668:2016+A1:2018, 5.1.2 a), 5.1.2 b),

5.1.2 c);

e) for experimental design method, the requirements of EN 16668:2016+A1:2018, 5.1.2 d);

f) for corrosion protection, the requirements of EN 16668:2016+A1:2018, 5.1.2 a), 5.1.2 b), 5.1.2 c);

g) for protection against exceeding the allowable limits of pressure equipment, the requirements of

EN 16668:2016+A1:2018, 5.1.3;

h) for permanent joining, the requirements of EN 16668:2016+A1:2018, 5.3.1.1, 5.3.1.2, 5.3.1.3,

5.3.1.4, 5.3.1.6;

i) for non destructive tests of permanent joints, the requirements of EN 16668:2016+A1:2018,

5.3.4;

j) for heat treatment, the requirements of EN 16668:2016+A1:2018, 5.3.2;

k) for traceability, the requirements of EN 16668:2016+A1:2018, 5.3.3;

l) for final inspection, the requirements of EN 16668:2016

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...