FprEN 18141

(Main)Railway applications - Braking - Emergency push button

Railway applications - Braking - Emergency push button

This document specifies the requirements for the function, design, performance, and testing of emergency push buttons that are installed in train’s driving’s cab.

This document is applicable for emergency push button.

This document is not applicable for emergency handle.

Bahnanwendungen - Bremsen - Notbremsschlagknopf

Dieses Dokument legt die Anforderungen an die Funktion, die Gestaltung, die Leistung, Installationsbeschränkungen und die Prüfung von Notbremsschlagknöpfen in Führerräumen von Schienenfahrzeugen fest.

Dieses Dokument ist für Notbremsschlagknöpfe anwendbar.

Dieses Dokument ist nicht für Notbremshandgriffe anwendbar.

Applications ferroviaires - Freinage - Bouton poussoir d'urgence

Le présent document spécifie les exigences relatives à la fonction, à la conception, aux performances, aux contraintes d’installation et aux essais des boutons poussoirs d’urgence installés dans la cabine de conduite des trains.

Le présent document s’applique au bouton-poussoir d’urgence.

Le présent document ne s’applique pas à la poignée de secours.

Železniške naprave - Zavore - Gumb za klic v sili

General Information

- Status

- Not Published

- Publication Date

- 06-May-2026

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 3/WG 47 - Braking

- Current Stage

- 5020 - Submission to Vote - Formal Approval

- Start Date

- 15-Jan-2026

- Due Date

- 11-Aug-2026

- Completion Date

- 15-Jan-2026

Overview

FprEN 18141 is a European standard developed by CEN that defines the requirements for emergency push buttons used in railway applications, specifically within train driving cabs. Its primary focus lies on the function, design, performance, and testing of these crucial safety devices which are dedicated to braking systems. The standard applies solely to emergency push buttons and explicitly excludes emergency handles.

This standard plays a vital role in ensuring that emergency push buttons perform reliably under various operational and environmental conditions, providing consistent and safe emergency brake activation for trains.

Key Topics

Functionality:

Emergency push buttons must have only two distinct positions-“no emergency brake application demanded” and “emergency brake application demanded”-which are mechanically notched. Activation is achieved by pressing the distinctive mushroom-shaped button, and release by pulling it. The device can function independently as an emergency brake demand device or additionally as a trainwide emergency brake control device.Design Requirements:

The emergency push button must have a clear external appearance with design features ensuring reliable application and release forces and defined push button stroke. It also needs to conform to fire and smoke safety requirements and accommodate specified pneumatic connections. Installation constraints and recommendations are addressed to ensure proper mounting inside the driving cab.Performance Under Environmental Conditions:

The push button must reliably operate under:- Shock and vibration per EN 61373 category 1, class B.

- Altitudes up to 2,000 meters above sea level.

- Ambient temperatures ranging from cold to +70 °C external air temperature.

- Wide humidity ranges including condensation and sudden temperature changes simulating tunnel conditions.

- Solar radiation with direct exposure taken into account.

- Various pollution scenarios involving chemical substances, fluids, dust, sand, and sea spray.

Pneumatic and Electrical Requirements:

Pneumatic components must withstand pressures above the compressed air supply limits, assure minimal leakage rates under varied air purity classes, and meet exhaust performance in line with EN 14198 braking standards. Electrical components must comply with electromagnetic compatibility and insulation requirements as per referenced standards.Testing and Assessment:

The standard specifies comprehensive type testing procedures, with tests for:- Physical and geometrical verification.

- Application and release controls.

- Vibration and shock resistance.

- Endurance under different temperatures.

- Corrosion and fire behavior.

- Pressure tightness, insulation, and dielectric strength.

In-service assessment and marking guidelines are also included to facilitate ongoing compliance and traceability.

Applications

FprEN 18141 is critical for manufacturers, suppliers, and operators involved in:

- Designing and certifying emergency push buttons for train driving cabs.

- Ensuring braking safety systems comply with European regulations and interoperability standards.

- Enhancing onboard safety equipment for locomotives and multiple units.

- Providing reliable emergency brake activation mechanisms that function correctly under severe environmental and operational stressors.

- Supporting maintenance and quality assurance processes through standardized testing and assessment methods.

Related Standards

FprEN 18141 references and complements several key railway and safety standards:

- EN 14198: Requirements for braking systems in locomotives.

- EN 45545-2: Fire protection standards for railway vehicles.

- EN 50121-3-2: Electromagnetic compatibility for rolling stock equipment.

- EN 50125-1: Environmental conditions for rolling stock.

- EN 50155: Electronic equipment on rolling stock.

- EN 61373: Shock and vibration testing for railway equipment.

- ISO 4975: Compressed air quality for pneumatic systems.

- EN ISO 24478: Vocabulary for railway braking systems.

By aligning with these standards, FprEN 18141 ensures emergency push buttons meet comprehensive safety, reliability, and interoperability criteria essential for modern railway operations.

Keywords: railway emergency push button, train braking safety, railway cab emergency button, emergency brake activation, railway safety standards, CEN railway standards, railway equipment testing, train braking system compliance, railway pneumatic controls, EN 18141 standard.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

FprEN 18141 is a draft published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Braking - Emergency push button". This standard covers: This document specifies the requirements for the function, design, performance, and testing of emergency push buttons that are installed in train’s driving’s cab. This document is applicable for emergency push button. This document is not applicable for emergency handle.

This document specifies the requirements for the function, design, performance, and testing of emergency push buttons that are installed in train’s driving’s cab. This document is applicable for emergency push button. This document is not applicable for emergency handle.

FprEN 18141 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

FprEN 18141 is associated with the following European legislation: EU Directives/Regulations: 2016/797/EU. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

FprEN 18141 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN 18141:2025

01-januar-2025

Železniške naprave - Zavore - Gumb za klic v sili

Railway applications - Braking - Emergency push button

Bahnanwendungen - Bremsen - Notbremsschlagknopf

Applications ferroviaires - Freinage - Bouton poussoir d'urgence

Ta slovenski standard je istoveten z: prEN 18141

ICS:

45.040 Materiali in deli za železniško Materials and components

tehniko for railway engineering

oSIST prEN 18141:2025 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

oSIST prEN 18141:2025

oSIST prEN 18141:2025

DRAFT

EUROPEAN STANDARD

prEN 18141

NORME EUROPÉENNE

EUROPÄISCHE NORM

November 2024

ICS 45.040

English Version

Railway applications - Braking - Emergency push button

Applications ferroviaires - Freinage - Bouton poussoir Bahnanwendungen - Bremsen - Notbremsschlagknopf

d'urgence

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 256.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 18141:2024 E

worldwide for CEN national Members.

oSIST prEN 18141:2025

prEN 18141:2024 (E)

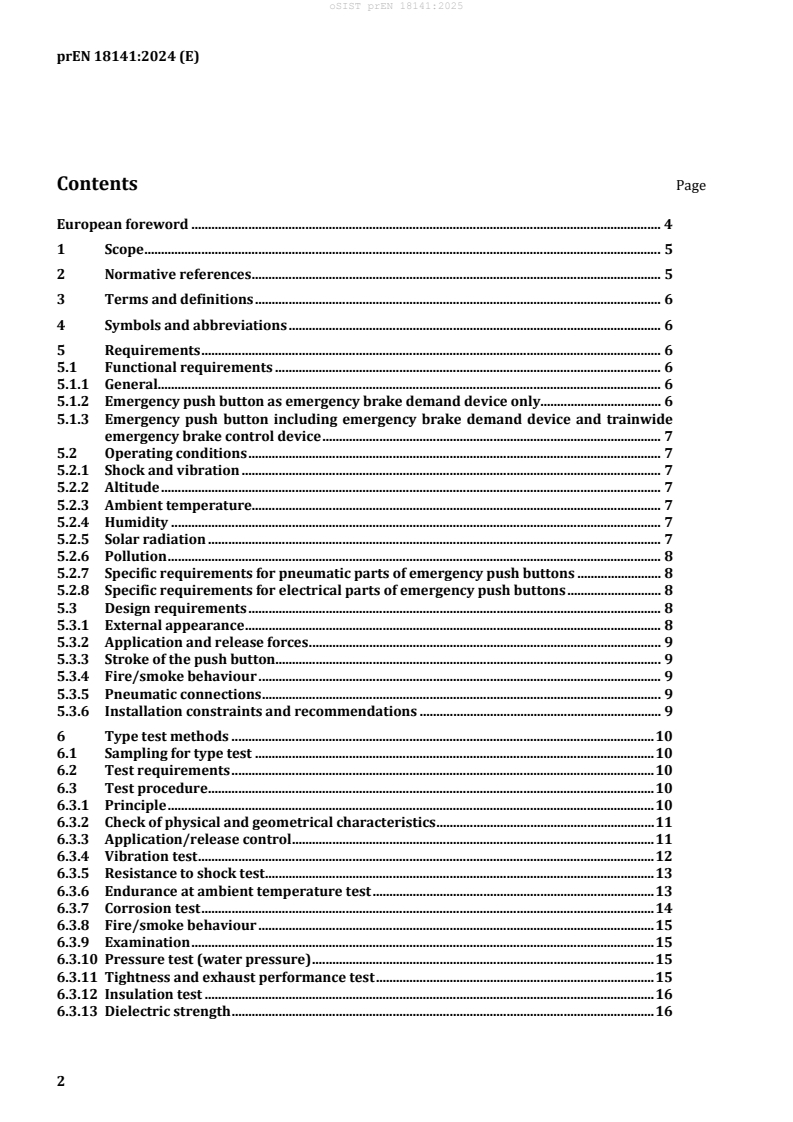

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Symbols and abbreviations . 6

5 Requirements . 6

5.1 Functional requirements . 6

5.1.1 General. 6

5.1.2 Emergency push button as emergency brake demand device only . 6

5.1.3 Emergency push button including emergency brake demand device and trainwide

emergency brake control device . 7

5.2 Operating conditions . 7

5.2.1 Shock and vibration . 7

5.2.2 Altitude . 7

5.2.3 Ambient temperature. 7

5.2.4 Humidity . 7

5.2.5 Solar radiation . 7

5.2.6 Pollution . 8

5.2.7 Specific requirements for pneumatic parts of emergency push buttons . 8

5.2.8 Specific requirements for electrical parts of emergency push buttons . 8

5.3 Design requirements . 8

5.3.1 External appearance . 8

5.3.2 Application and release forces . 9

5.3.3 Stroke of the push button. 9

5.3.4 Fire/smoke behaviour . 9

5.3.5 Pneumatic connections . 9

5.3.6 Installation constraints and recommendations . 9

6 Type test methods . 10

6.1 Sampling for type test . 10

6.2 Test requirements . 10

6.3 Test procedure . 10

6.3.1 Principle . 10

6.3.2 Check of physical and geometrical characteristics . 11

6.3.3 Application/release control . 11

6.3.4 Vibration test . 12

6.3.5 Resistance to shock test . 13

6.3.6 Endurance at ambient temperature test . 13

6.3.7 Corrosion test . 14

6.3.8 Fire/smoke behaviour . 15

6.3.9 Examination . 15

6.3.10 Pressure test (water pressure) . 15

6.3.11 Tightness and exhaust performance test . 15

6.3.12 Insulation test . 16

6.3.13 Dielectric strength . 16

oSIST prEN 18141:2025

prEN 18141:2024 (E)

7 In-service assessment . 16

8 Marking . 16

Annex A (normative) Dimensions, shape and colour of the mushroom button . 17

Annex B (informative) In-service assessment . 19

Bibliography . 20

oSIST prEN 18141:2025

prEN 18141:2024 (E)

European foreword

This document (prEN 18141:2024) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

oSIST prEN 18141:2025

prEN 18141:2024 (E)

1 Scope

This document specifies the requirements for the function, design, performance, and testing of

emergency push buttons that are installed in train’s driving’s cab.

This document is applicable for emergency push button.

This document is not applicable for emergency handle.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 14198:2016+A2:2021, Railway applications - Braking - Requirements for the brake system of trains

hauled by locomotives

EN 45545-2:2020+A1:2023, Railway applications - Fire protection on railway vehicles - Part 2:

Requirements for fire behaviour of materials and components

EN 50121-3-2:2016, Railway applications — Electromagnetic compatibility — Part 3-2: Rolling stock —

Apparatus

EN 50125-1:2014, Railway applications - Environmental conditions for equipment - Part 1: Rolling stock

and on-board equipment

EN 50155:2021, Railway applications - Rolling stock - Electronic equipment

EN 60721-3-5:1997, Classification of environmental conditions — Part 3: Classification of groups of

environmental parameters and their severities — Section 5: Ground vehicle installations (IEC 60721 3

5:1997)

EN 61373:2010, Railway applications - Rolling stock equipment - Shock and vibration tests (IEC

61373:2010)

EN ISO 228-2:2003, Pipe threads where pressure-tight joints are not made on the threads - Part 2:

Verification by means of limit gauges (ISO 228-2:1987)

EN ISO 24478:2024, Railway applications - Braking - General vocabulary (ISO 24478:2023, including

corrected version 2024-04)

EN ISO 6270-2:2018, Paints and varnishes - Determination of resistance to humidity - Part 2: Condensation

(in-cabinet exposure with heated water reservoir) (ISO 6270-2:2017)

EN ISO 9227:2022, Corrosion tests in artificial atmospheres —Salt spray tests (ISO 9227:2022)

ISO 5208:2015, Industrial valves — Pressure testing of metallic valves

ISO 4975:2022, Railway applications — Braking system — Quality of compressed air for pneumatic

apparatus and systems

As impacted by EN 50121-3-2:2016/A1:2019.

As impacted by EN ISO 9227:2022/A1:2024.

oSIST prEN 18141:2025

prEN 18141:2024 (E)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 24478:2024 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

emergency push button

emergency brake demand device fitted with a red mushroom button for the driver that is independent

and separated from other driver’s brake demand device

Note 1 to entry: This device can also function as an emergency brake trainwide control device.

[SOURCE: EN ISO 24478:2024, 3.10.1.8, modified — admitted term “emergency handle” deleted, Note 1

to entry moved to definition.]

3.2

mushroom button

part of the emergency push button in interface with the driver with a shape of mushroom

4 Symbols and abbreviations

For the purposes of this document, the following symbols in Table 1 apply.

Table 1 — Symbols

Symbol Description Unit

U Nominal voltage V

n

DC Direct current —

5 Requirements

5.1 Functional requirements

5.1.1 General

Only two positions shall be possible for the emergency push button: “no emergency brake application

demanded” and “emergency brake application demanded”. These two positions shall be notched.

Switching from “no emergency brake application demanded” to “emergency brake application

demanded” shall be done by pushing on the mushroom button.

Switching from “emergency brake application demanded” to “no emergency brake application

demanded” shall be done by pulling the mushroom button.

5.1.2 Emergency push button as emergency brake demand device only

The emergency brake demand signal shall be controlled directly by the position of the mushroom button.

oSIST prEN 18141:2025

prEN 18141:2024 (E)

The emergency brake demand signal controlled by the emergency push button shall be in accordance

with the principle “deactivate-to-apply”, i.e. no signal shall mean “emergency brake application

demanded”.

5.1.3 Emergency push button including emergency brake demand device and trainwide

emergency brake control device

The trainwide emergency brake control signal controlled by the trainwide emergency brake control

device of the emergency push button shall be mechanically linked to the position of the mushroom button.

5.2 Operating conditions

5.2.1 Shock and vibration

The emergency push button shall be able to operate without restriction under shock and vibration

conditions as specified in EN 61373:2010, category 1, class B, body mounted. This shall be tested in

accordance with 6.3.4 and with 6.3.5.

5.2.2 Altitude

The emergency push button shall be able to operate without restrictions up to an altitude of 2 000 m

above sea level.

5.2.3 Ambient temperature

The emergency push button shall be able to operate within the temperature class TX as specified by

EN 50125-1:2014, where the upper limit for TX is +70 °C external air temperature. This requirement shall

be tested in accordance with 6.3.

5.2.4 Humidity

The following external humidity levels shall be considered:

— yearly average: ≤ 75 % relative humidity;

— on 30 days in the year continuously: between 75 % and 95 % relative humidity;

— on the other days occasionally: between 95 % and 100 % relative humidity;

— maximum absolute humidity: 30 g/m occurring in tunnels.

An operationally caused infrequent and slight moisture condensation shall not lead to any malfunction

or failure.

At cooled surfaces, 100 % relative humidity can occur, causing condensation on parts of equipment; this

shall not lead to any malfunction or failure.

Sudden lowering of the air temperature local to the vehicle can cause condensation of water on parts of

equipment with rate of 3 K/s and maximum fall in temperature of 40 K.

These conditions particularly occurring when entering or leaving a tunnel shall not lead to any

malfunction or failure of the equipment.

To withstand the external corrosion due to normal atmospheric pollutants as specified in

EN 50125-1:2014, the emergency push button shall be tested in accordance with 6.3.7.

5.2.5 Solar radiation

Equipment design shall allow for direct exposure to solar radiation in accordance with the class R2 of

EN 50125-1:2014, 4.9 for parts exposed (e.g. mushroom button).

oSIST prEN 18141:2025

prEN 18141:2024 (E)

5.2.6 Pollution

The effects of pollution shall be considered in the design of equipment and components. The effects of the

kinds of pollution indicated in Table 2 shall be considered as a minimum.

Table 2 — Pollution

Pollution Requirements

Chemically active substances Class 5C2 of EN 60721-3-5:1997

Contaminating fluids Class 5F2 (electrical engine) of EN 60721-3-5:1997

Class 5F3 (thermal engine) of EN 60721-3-5:1997

Biologically active substances Class 5B2 of EN 60721-3-5:1997

Dust Class 5S2 of EN 60721-3-5:1997

Sand Class 5S2 of EN 60721-3-5:1997

Sea spray Class 5C2 of EN 60721-3-5:1997

Compatibility of a cleaning product should be considered in the design of equipment.

5.2.7 Specific requirements for pneumatic parts of emergency push buttons

To respect the upper pressure limit of the compressed air supply of 10 bar, the emergency push button

shall be able to withstand a hydraulic test with a pressure of 15 bar in accordance with 6.3.10.

It shall be possible to operate the pneumatic parts of emergency push buttons without restrictions with

at least the compressed air purity 3-3-4 [−25 °C; 50 °C] in accordance with ISO 4975:2022.

When not activated, the loss of pressure of the emergency push button at 5,0 bar shall be less than

0,005 Nl per minute for temperature between 0 °C and 40 °C and less than a value defined linearly from

0,005 Nl to 0,10 Nl between 0 °C and −40 °C, and between 40 °C and 70 °C.

When used with degraded compressed air purity 3-6-4 [−25 °C; 50 °C] in accordance with ISO 4975:2022,

the loss of pressure of the emergency push button at 5,0 bar shall be less than two times the one allowed

with the air purity 3-3-4 [−25 °C; 50 °C] in accordance with ISO 4975:2022.

If emergency push button includes a pneumatic trainwide emergency brake control device, when

activated, the emergency push button shall have the same exhaust performance as the emergency brake

application of EN 14198:2016+A2:2021, Clause E.4 for both air purities 3-3-4 and 3-6-4. These

performances shall be tested in accordance with 6.3.11.

5.2.8 Specific requirements for electrical parts of emergency push buttons

The electrical parts of emergency push buttons shall be in conformity with the requirements of

EN 50155:2021 and EN 50121-3-2:2016 , if applicable. These performances shall be tested in accordance

with 6.3.12 and 6.3.13

When the voltage supply is at upper and lower limit the emergency push button shall be able to withstand

the temperature range in accordance with 6.3.3.

5.3 Design requirements

5.3.1 External appearance

The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...