EN 15309:2007

(Main)Characterization of waste and soil - Determination of elemental composition by X-ray fluorescence

Characterization of waste and soil - Determination of elemental composition by X-ray fluorescence

This European Standard specifies the procedure for a quantitative determination of major and trace element concentrations in homogeneous solid waste, soil and soil-like material by energy dispersive X-ray fluorescence (EDXRF) spectrometry or wavelength dispersive X-ray fluorescence (WDXRF) spectrometry using a calibration with matrix-matched standards.

This European Standard is applicable for the following elements: Na, Mg, Al, Si, P, S, Cl, K, Ca, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, As, Se, Br, Rb, Sr, Y, Zr, Nb, Mo, Ag, Cd, Sn, Sb, Te, I, Cs, Ba, Ta, W, Hg, Tl, Pb, Bi, Th and U. Concentration levels between approximately 0,000 1 % and 100 % can be determined depending on the element and the instrument used.

Charakterisierung von Abfällen und Böden - Bestimmung der elementaren Zusammensetzung durch Röntgenfluoreszenz-Analyse

Caractérisation des déchets et du sol - Détermination de la composition élémentaire par fluorescence X

La présente norme européenne décrit le mode opératoire de détermination quantitative des concentrations en éléments majeurs et en éléments traces dans les sols, les matériaux de type sol et les déchets solides homogènes à l’aide de spectromètres de fluorescence X à dispersion d’énergie (EDXRF) ou de spectromètres de fluorescence X à dispersion de longueur d’onde (WDXRF), en utilisant un étalonnage réalisé avec des matériaux de référence adaptés à la matrice.

La présente norme européenne est applicable aux éléments suivants : Na, Mg, Al, Si, P, S, Cl, K, Ca, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, As, Se, Br, Rb, Sr, Y, Zr, Nb, Mo, Ag, Cd, Sn, Sb, Te, I, Cs, Ba, Ta, W, Hg, Tl, Pb, Bi, Th et U. Il est possible de déterminer des niveaux de concentration compris entre 0,0001 % et 100 % selon l’élément dosé et l’instrument utilisé.

Karakterizacija odpadkov in zemljine - Določevanje elementne sestave z rentgensko fluorescenco

General Information

- Status

- Withdrawn

- Publication Date

- 08-May-2007

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 444 - Environmental characterization

- Drafting Committee

- CEN/TC 444/WG 3 - Inorganic analysis

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Dec-2025

- Completion Date

- 28-Jan-2026

- Directive

- 99/31/EC - Landfill of waste

Relations

- Effective Date

- 02-Nov-2022

- Refers

EN 15002:2015 - Characterization of waste - Preparation of test portions from the laboratory sample - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 15309:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Characterization of waste and soil - Determination of elemental composition by X-ray fluorescence". This standard covers: This European Standard specifies the procedure for a quantitative determination of major and trace element concentrations in homogeneous solid waste, soil and soil-like material by energy dispersive X-ray fluorescence (EDXRF) spectrometry or wavelength dispersive X-ray fluorescence (WDXRF) spectrometry using a calibration with matrix-matched standards. This European Standard is applicable for the following elements: Na, Mg, Al, Si, P, S, Cl, K, Ca, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, As, Se, Br, Rb, Sr, Y, Zr, Nb, Mo, Ag, Cd, Sn, Sb, Te, I, Cs, Ba, Ta, W, Hg, Tl, Pb, Bi, Th and U. Concentration levels between approximately 0,000 1 % and 100 % can be determined depending on the element and the instrument used.

This European Standard specifies the procedure for a quantitative determination of major and trace element concentrations in homogeneous solid waste, soil and soil-like material by energy dispersive X-ray fluorescence (EDXRF) spectrometry or wavelength dispersive X-ray fluorescence (WDXRF) spectrometry using a calibration with matrix-matched standards. This European Standard is applicable for the following elements: Na, Mg, Al, Si, P, S, Cl, K, Ca, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, As, Se, Br, Rb, Sr, Y, Zr, Nb, Mo, Ag, Cd, Sn, Sb, Te, I, Cs, Ba, Ta, W, Hg, Tl, Pb, Bi, Th and U. Concentration levels between approximately 0,000 1 % and 100 % can be determined depending on the element and the instrument used.

EN 15309:2007 is classified under the following ICS (International Classification for Standards) categories: 13.030.10 - Solid wastes; 13.080.10 - Chemical characteristics of soils. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15309:2007 has the following relationships with other standards: It is inter standard links to EN ISO 18227:2025, EN 15002:2015, EN ISO 11465:2025, EN 4681-002:2012, EN 14399-4:2005, EN 12201-2:2011+A1:2013, EN 12201-2:2011, EN ISO 3884:2025, EN ISO 16486-3:2020, EN ISO 16486-3:2025, EN 13121-2:2003, EN 12201-2:2024, EN 12201-3:2011+A1:2012, EN 12201-3:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15309:2007 is associated with the following European legislation: EU Directives/Regulations: 99/31/EC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15309:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Characterization of waste and soil - Determination of elemental composition by X-ray fluorescenceCaractérisation des déchets et du sol - Détermination de la composition élémentaire par fluorescence XCharakterisierung von Abfällen und Böden - Bestimmung der elementaren Zusammensetzung durch Röntgenfluoreszenz-AnalyseTa slovenski standard je istoveten z:EN 15309:2007SIST EN 15309:2007en13.080.10Chemical characteristics of soils13.030.10Trdni odpadkiSolid wastesICS:SLOVENSKI

STANDARDSIST EN 15309:200701-oktober-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15309May 2007ICS 13.030.10; 13.080.10 English VersionCharacterization of waste and soil - Determination of elementalcomposition by X-ray fluorescenceCaractérisation des déchets et du sol - Détermination de lacomposition élémentaire par fluorescence XCharakterisierung von Abfällen und Böden - Bestimmungder elementaren Zusammensetzung durchRöntgenfluoreszenz-AnalyseThis European Standard was approved by CEN on 22 March 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15309:2007: E

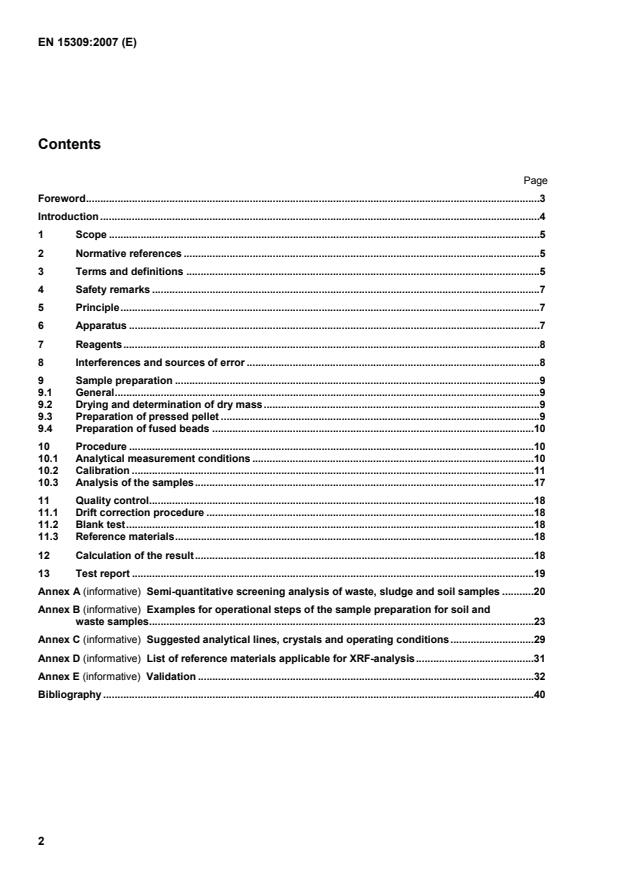

Semi-quantitative screening analysis of waste, sludge and soil samples.20 Annex B (informative)

Examples for operational steps of the sample preparation for soil and waste samples.23 Annex C (informative)

Suggested analytical lines, crystals and operating conditions.29 Annex D (informative)

List of reference materials applicable for XRF-analysis.31 Annex E (informative)

Validation.32 Bibliography.40

Annex A which provides a total element characterisation at a semi-quantitative level. The calibration is based on matrix-independent calibration curves, previously set up by the manufacturer.

X-radiation as it passes through an absorbing medium, expressed in units of cm2/g. The mass absorption coefficient is a function of the wavelength of the absorbed radiation and the atomic number of the absorbing element 3.11 polarised excitation X-ray spectrometer energy dispersive X-ray spectrometer where the excitation is performed by polarised radiation and the emitted X-ray fluorescence radiation is detected along the direction of polarisation 3.12 powder sample analyte sample submitted as a powder for direct measurement in the sample cup 3.13 precision closeness of agreement of results obtained by applying the method several times under prescribed conditions [ISO 5725-2:1994] 3.14 pressed pellet analyte sample prepared by pressing milled material into a disk 3.15 primary X-rays X-rays by which the sample is radiated 3.16 quality control sample stable sample with known contents, e.g. certified reference material (CRM) used to monitor instrument and calibration performance

6 Apparatus 6.1 X-ray fluorescence spectrometer The X-ray fluorescence spectrometer shall be able to analyse the elements according to the scope of this European Standard. The following types of X-ray fluorescence spectrometers are applicable: energy dispersive X-ray fluorescence (EDXRF) spectrometer that achieves the dispersion of the emitted X-ray fluorescence radiation by an energy dispersive detector; wavelength dispersive X-ray fluorescence (WDXRF) spectrometer that achieves the dispersion of the emitted X-ray fluorescence radiation by diffraction by a crystal or a synthetic multilayer. The spectrometer consists of a number of components: primary X-ray source, an X-ray tube with a high voltage generator; a sample holder; detector unit including electronic equipment; source modifiers to modify the shape or intensity of the source spectrum or the beam shape (like source filters, secondary targets, polarising targets, collimators, focussing optics etc.).

9.4 Preparation of fused beads After drying and milling or grinding the sample, a fused bead is prepared using the fusion apparatus (6.5). Ignite the sample at an appropriate temperature until constant mass is reached. Determine the loss on ignition at the same temperature to correct for volatile elements and/or compounds being released during ignition of the sample. NOTE 1 The ignition temperature can vary depending on the sample matrix. A temperature commonly used is 1025°C ± 25°C.

Because of the wide applicability of the fused bead technique, various fluxes and modes of calibration are permitted providing they have been demonstrated to be able to meet certain criteria of reproducibility, sensitivity and accuracy. For application of alkaline fusion technique (e.g. selection of flux, fusion temperature, additives) ISO 14869-2 or CEN/TR 15018 should be used. NOTE 2 Fluxes commonly used are lithium metaborate, lithium tetraborate or mixtures of both. NOTE 3 Loss of volatile elements e.g. As, Br, Cd, Cl, Hg, I, S , Sb, Se, Tl may occur during the ignition and fusion processes. Also Cu may be volatile if a bromide releasing agent is used. The flux (7.2) is added to the ignited material. For the preparation of 40 mm diameter beads, about 1,6 g of ignited sample is taken, for 32 mm diameter beads about 0,8 g of ignited sample is required. The amount of flux in the bead shall be taken into account for the dilution factor. The same sample preparation procedure and ratio of sample to flux shall be used for samples and standards. The beads produced should be visually homogeneous and transparent. NOTE 4 Non ignited material may be used to prepare beads but, nevertheless, loss of ignition needs to be determined and needs to be taken into account in the calculation of the results. It should be noted that non ignited material may contain compounds that can damage the platinum crucibles during fusion. NOTE 5 Different dilution factors may be used. A proportion of sample: flux commonly used is 1:5 by weight. After fusion in a platinum-gold crucible (6.6) the melt is poured into a casting mould (6.7) to make a bead. NOTE 6 Beads can deteriorate because of adverse temperature and humidity conditions, so it is recommended that beads are stored in desiccators. 10 Procedure 10.1 Analytical measurement conditions 10.1.1 Wavelength dispersive instruments The analytical lines to be used and suggested operating conditions are given in Table C.1. The settings are strongly dependant on the spectrometer configuration, e.g. the type of X-ray tube (Rh, Cr), tube power, available crystals, type of collimators.

bpIII−= (1) where

pI is the count rate of the element i, expressed as the number of counts per second;

bI is the background count rate of the element i, expressed as the number of counts per second. Counting time The minimum counting time is the time necessary to achieve an uncertainty (%2σ), which is less than the desired precision of the measurement. Choose a reference material with a concentration level in the middle of the working range and measure the count rate. The counting time for each element can be calculated according to:

2bp%1.2100−=IItσ (2) where

t is the total counting time for the peaks and background in seconds;

%2σ is the relative target precision at a confidence level of 95 %, expressed as percentage. 10.1.2 Energy dispersive instruments The analytical lines to be used and suggested operating conditions are given in Table C.2. The settings are strongly dependant on the spectrometer configuration, e.g. type of X-ray tube (Rh, Pd), tube power, available targets, type of filters. Intensities and background corrections Deconvolution of the spectra and background correction are needed when analysing samples with overlapping lines. Usually XRF-instruments are supplied with a specific software module for that purpose. 10.2 Calibration 10.2.1 General The calibration procedure is similar for energy dispersive and wavelength dispersive techniques. In general calibration is established by using matrix-adapted reference materials. The calibration equations and inter-element corrections are calculated by the software of the instrument. An accuracy check is performed with CRMs or samples with known composition.

Different procedures for correcting matrix effects may be used according to the analytical accuracy required: the scattered radiation method is based on the principle that the intensities of the analyte line and of the Compton line are affected in the same proportion due to the overall mass absorption coefficient of the sample. This linear relationship holds when all analytes are at low concentrations (trace elements) and their absorption coefficients are not affected by an adjacent absorption edge. In this case an internal Compton correction can be used. Beside that, a correction method using the Compton intensity with Mass Absorption Coefficients (MAC) is also applicable. In this method, the intensities of the major elements are measured to apply a jump edge correction for the analysed trace elements; correction using the fundamental parameter approach; correction using theoretical correction coefficients (alphas) taking basic physical principles, instrumental geometry etc. into account; correction using empirical correction coefficients (alphas) based on regression analysis of standards with known elemental concentrations. 10.2.2 General calibration procedure For calibration purposes the measurement of analyte lines of samples of known composition is needed. The basic equation implies a linear relationship between the intensity and the concentration.

ii,1i,0i.IaaC+= (3) where

iC is the concentration of the element of interest, expressed as mg/kg or percentage dry matter;

i,0a is the offset of the calibration curve;

i,1a is the slope of the calibration curve;

iI is the net intensity of the element of interest, expressed as counts per second. Matrix effects have to be taken into account in X-ray spectrometry according to the following equation:

MIaaC.).(ii,1i,0i+= (4) where

M is the correction term due to the matrix effects.

The matrix effect correction term may consist of an internal standard Compton correction method or may be calculated from mathematical models. 10.2.3 Internal standard correction using Compton (incoherent) scattering method The measured intensity of incoherent scattering may be used directly to compensate for matrix effects or indirectly for the determination of the effective mass absorption coefficient µ to correct for matrix effects. The compensation for matrix effects is based on a combination of sample preparation and experimental intensity data but not on fundamental and experimental parameters.

)(.).(uinc,ui,ri,rinc,ri,ui,IIIICC= (5) where

ui,C is the concentration of the element of interest i of the sample, expressed as mg/kg or percentage dry matter;

ri,C is the concentration of the element of interest i of the calibration reference material, expressed as mg/kg or percentage dry matter;

uinc,I is the intensity of the incoherent Compton line of the sample, expressed as counts per second;

rinc,I is the intensity of the incoherent Compton line element of the calibration reference material, expressed as counts per second;

ui,I is the intensity of the element of interest i of the sample, expressed as counts per second;

ri,I is the intensity of the element of interest i of the calibration reference material, expressed as counts per second. 10.2.4 Fundamental parameter approach The fundamental parameter approach uses the physical processes forming the basis of X-ray fluorescence emission and scattering to construct a theoretical model for the correction of matrix effects in practice. The correction term M is calculated from first principle expressions. These are derived from basic X-ray physics and contain physical constants and parameters that include absorption and scattering coefficients, fluorescence yield, primary spectral distributions and spectrometry geometry. The use of scattered radiation (Compton and/or Rayleigh) allows the determination of matrix effects caused by sample elements that cannot be measured directly. The calculation of analyte concentrations in samples is based on making successively better estimates of composition by an iteration procedure. These iteration cycles are performed until the difference between the compared results is below a defined value. NOTE The algorithm used for the procedure is usually implemented in the manufacturer’s software. 10.2.5 Fundamental or theoretical influence coefficient method The fundamental influence coefficient method encompasses any mathematical expression relating emitted intensities and concentrations in which the influence coefficients are defined and derived explicitly in terms of fundamental parameters. The calculation of the concentration from the intensities is performed by linear regression whereby the net intensities are corrected for the present matrix effects. For each element the concentration is calculated according to the following equation:

MICICCj.)1(ui,jrijri,ri,ui,+=∑α (6)

++=∑∑jjCICICCjuijui,jrijri,ri,ui,1.)1(αα (7) where

ui,C is the concentration of the element of interest i of the sample, expressed as mg/kg or percentage dry matter;

ri,C is the concentration of the element of interest i of the calibration reference material, expressed as mg/kg or percentage dry matter;

ri,I is the intensity of the element of interest i of the calibration reference material, expressed as counts per second;

ui,I is the intensity of the element of interest i of the sample, expressed as counts per second;

rj,C

is the concentration of the matrix element j of the calibration reference material, expressed as mg/kg or percentage dry matter;

uj,C

is the concentration of the matrix element j of the sample, expressed as mg/kg or percentage dry matter;

M is the matrix correction term;

ijα is the correction coefficient ijα (called alphas) calculated from theory, although some approximations are involved. Different types of alpha coefficient exist, but all of them are calculated without reference to experimental data; they are calculated using intensity data resulting from a fundamental parameter expression. The alpha coefficients vary as a function of sample composition and are calculated by an iterative process. 10.2.6 Empirical alpha correction Empirical alphas are obtained experimentally using regression analysis of data from reference materials in which the elements to be measured are known and the total concentration range is covered. Best results are achieved when the samples and reference materials are of similar composition. Thus, empirical alphas are based strictly on experimental data and do not take fundamental and instrumental parameters into account. Different models can be applied, but generally they are based on the above equation where the correction term for matrix effects is a function of concentrations. The empirical alphas are only applicable for a limited concentration range and a well-defined analytical method where the matrices of samples and standards are similar. The reference materials used should contain each analyte together with fairly wide concentration ranges of each matrix element. Poor analytical results are obtained when inappropriate combinations of analytes are chosen. A large number of reference materials have to be analysed to define the alphas (rule of thumb: minimum of 3 times the number of parameters to be calculated). 10.2.7 Calibration procedure for trace elements using the pressed pellet method The pressed pellet method is used to determine the concentrations of trace elements. Select calibration standards with a similar composition as the samples under investigation containing the elements of interest and covering the concentration range of interest. The use of reference materials from different recognised producers is recommended (see Annex D) or synthetic mixtures of oxides may be

Table 1 the possible spectral line overlaps are indicated (dependant on the configuration of the instrument) and also the matrix correction method that can be applied. For trace elements with an absorption edge above the absorption edge of iron, a Compton internal standard correction can be applied. Otherwise a theoretical alpha correction or correction for the absorption edge should be performed (for these corrections all elements in the sample have to be analysed). Depending on the type of instrument and the software programs available, alternative correction methods can be applied. Validation of the final calibration curves shall demonstrate the accuracy of the method. Perform the regression calculation and verify that the correlation factors are within the limits of accuracy required.

Table 1 — Suggested analytical lines, spectral line overlaps and correction methods Element Line Spectral line overlap Type of matrix correction method Na Kα ZnLβ Alpha or FP Mg Kα AsLα Alpha or FP

Al Kα BrLα Alpha or FP

Si Kα

Alpha or FP

P Kα

Alpha or FP

S Kα CoKα

PbMα

NbLβAlpha or FP or MAC Cl Kα

Alpha or FP or MAC K Kα

Alpha or FP Ca Kα

Alpha or FP

Ti Kα BaLα ΙLβ Alpha or FP V Kα Ti Kβ

Alpha or FP or MAC Cr Kα VKβ

PbLα Alpha or FP or MAC Mn Kα CrKβ

Alpha or FP

Fe Kα MnKβ Alpha or FP

Co Kα FeKβ Alpha or FP or MAC Ni Kα CoKβ Compton or FP or MAC Cu Kα TaLα ThLβ Compton or FP or MAC Zn Kα WLα Compton or FP or MAC As Kα

Kβ PbLα BrKα Compton or FP or MAC Se Kα

Compton or FP or MAC Br Kα AsKβ Compton or FP or MAC Rb Kα ULα BrKβ

Compton or FP or MAC Sr Kα ULα Compton or FP or MAC Y Kα RbKβ Compton or FP or MAC Zr Kα SrKβ Compton or FP or MAC Nb Kα YKβ ULβ Compton or FP or MAC Mo Kα ZrKβ ULβ Compton or FP or MAC Ag Kα Lα

CrKβ Compton or FP or MAC Alpha or FP

Cd Kα Lα

AgLβ Compton or FP or MAC Alpha or FP

Sn Kα Lα

CoKα Compton or FP or MAC Alpha or FP or MAC Sb Kα Lβ

CoKβ Compton or FP or MAC Alpha or FP or MAC Te Kα Lα

SnLβ Compton or FP or MAC Alpha or FP or MAC I Kα Lα

Compton or FP or MAC Alpha or FP or MAC Cs Kα Lα

ZnKα ILβ Compton or FP or MAC Alpha or FP or MAC Ba Kα Lα

TiKα ILβ CuKβ Compton or FP or MAC Alpha or FP or MAC Ta Lα CuKα NiKβ Compton or FP or MAC W Lα TaLn Compton or FP or MAC Hg Lα WLβ Compton or FP or MAC Tl Lβ PbLβ Compton or FP or MAC

Table 1 the possible spectral line overlaps are indicated (dependant on the configuration of the instrument). For all elements an alpha correction method using theoretical alphas should be applied. Depending on the type of instrument and the software programs available, alternative correction methods can be applied. Validation of the final calibration curves shall demonstrate the accuracy of the method. Perform the regression calculation and verify that the correlation factors are within the limits of accuracy required. 10.3 Analysis of the samples Follow the instrument manufacturer’s instructions for set up, conditioning, preparation and maintenance of the XRF spectrometer. Select the required preparation method and prepare the samples. For the quantification of trace elements the pressed pellet method is recommended and for the determination of major and minor elements the fused bead method should be used. To analyse the prepared samples, an analytical measurement method has to be defined. The measurement method describes the analytical lines to be measured and the measurement parameters e.g. the XRF generator settings (tube voltage and current), selection of primary beam filters, targets and crystals, detector to be used, measurement time. The same measurement parameters used for the calibration according to 10.2 are applied to the samples.

13 Test report The work carried out by the testing laboratory shall be covered by a report which accurately, clearly and unambiguously presents the test results and all other relevant information as specified in EN ISO/IEC 17025. In addition to test results the test report shall include at least the following information: a) description and identification of the laboratory sample; b) which processes, procedures and apparatus were used; c) results of the determination expressed as mg/kg dm or mass percentages dm; d) any details not specified in this European Standard or which are optional, and any other factors which may have affected the re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...