CEN/TS 13001-3-1:2004

(Main)Cranes - General design - Part 3-1: Limit states and proof of competence of steel structures

Cranes - General design - Part 3-1: Limit states and proof of competence of steel structures

This European Standard is to be used together with Part 1 and Part 2 and as such they specify general conditions, requirements and methods to prevent mechanical hazards of cranes by design and theoretical verification.

NOTE Specific requirements for particular types of crane are given in the appropriate European Standard for the particular crane type.

The following is a list of significant hazardous situations and hazardous events that could result in risks to persons during normal use and foreseeable misuse. Clauses 4 to 8 of this standard are necessary to reduce or eliminate the risks associated with the following hazards:

a) Exceeding the limits of strength (yield, ultimate, fatigue);

b) Exceeding temperature limits of material or components;

c) Elastic instability of the crane or its parts (buckling, bulging).

This European Standard is applicable to cranes which are manufactured after the date of approval by CEN of this standard and serves as reference base for the European Standards for particular crane types.

NOTE prCEN/TS 13001-3-1 deals only with limit state method according to prEN 13001-1.

As an alternative to the herein presented limit state method using partial safety factors, the allowable stress method using a global safety factor according to prEN 13001-1 and prEN 13001-2 may also be applied for special crane systems with linear behaviour.

As crane structures are basically dynamically loaded only the linear theory of elasticity is applicable and only limited local plasticity is allowed. The use of the theory of plasticity for calculation of ultimate load bearing capacity is not allowed.

Krane - Konstruktion allgemein - Teil 3-1: Grenzzustände und Sicherheitsnachweis von Stahltragwerken

Diese Europäische Norm findet zusammen mit Teil 1 und Teil 2 Anwendung. Sie spezifizieren allgemeine

Bedingungen, Anforderungen und Methoden zur Vermeidung mechanischer Gefahren von Kranen durch

Konstruktion und theoretische Nachweisverfahren.

ANMERKUNG 1 Spezifische Anforderungen für spezielle Krantypen sind in der jeweiligen Europäischen Norm für den

konkreten Krantyp enthalten.

Im folgenden sind signifikante Gefahrensituationen und gefährliche Ereignisse aufgeführt, die Risiken für

Personen bei Normaleinsatz und vorhersehbarem Missbrauch zur Folge haben könnten. Die Abschnitte 4 bis

8 dieser Norm enthalten Vorgaben zur Verminderung oder Ausschaltung von Risiken, die mit folgenden

Gefahren verbunden sind:

a) Überschreiten der Festigkeitsgrenzwerte (Fließen, Bruch, Ermüdung);

b) Überschreiten der Temperaturgrenzwerte des Werkstoffs oder der Komponenten;

c) Elastische Instabilität des Krans oder seiner Teile (Knicken, Beulen).

Diese Europäische Norm gilt für Krane, die nach dem Datum der Genehmigung dieser Norm durch CEN

gefertigt werden, und dient als Referenzgrundlage für Europäische Normen für spezielle Krantypen.

ANMERKUNG 2 prCEN/TS 13001-3.1 beinhaltet nur die Methode der Grenzzustände entsprechend EN 13001-1.

Alternativ zu der hierin genannten Methode der Grenzzustände unter Verwendung von

Teilsicherheitsbeiwerten, kann der zulässige Spannungsnachweis unter Verwendung des

Gesamtsicherheitsbeiwertes nach EN 13001-1 und EN 13001-2 auch für spezielle Krananlagen mit linearem

Verhalten angewendet werden.

Da Krankonstruktionen grundsätzlich dynamisch belastet werden, ist nur die lineare Elastizitätstheorie

anwendbar und nur die begrenzte örtliche Plastizität zulässig. Die Anwendung der Plastizitätstheorie zur

Berechnung der Grenztragfähigkeit ist nicht zulässig.

Appareils de levage à charge suspendue - Conception générale - Partie 3-1: Etats limites et vérification d'aptitude des structures en acier

La présente Norme européenne doit être utilisée conjointement avec les parties 1 et 2 pour spécifier les conditions, prescriptions et méthodes générales permettant par la conception et la vérification théorique d'éviter les risques mécaniques dus aux appareils de levage à charge suspendue.

NOTE Les prescriptions spécifiques relatives aux types particuliers de grues sont données dans la norme européenne appropriée au type particulier de grue.

La liste suivante énumère les situations et les événements dangereux significatifs susceptibles d'entraîner des risques pour les personnes lors d'une utilisation normale ou d'une mauvaise utilisation prévisible. Les articles 4 à 8 de la présente norme sont nécessaires pour réduire ou éliminer les risques associés à ces phénomènes dangereux :

a) Dépassement des limites de résistance (élasticité, rupture, fatigue) ;

b) Dépassement des limites de température du matériau ou des composants ;

c) Instabilité élastique de l'appareil de levage à charge suspendue ou de ses éléments (flambage, voilement).

La présente Norme européenne s'applique aux appareils de levage à charge suspendue construits après sa date d'approbation par le CEN et sert de référence pour les normes européennes sur les types de l'appareil de levage à charge suspendue particuliers.

NOTE Le prCEN/TS 13001-3-1 traite uniquement de la méthode des états limites selon le prEN 13001-1.

La méthode des contraintes admissibles utilisant un facteur global de sécurité selon les prEN 13001-1 et prEN 13001-2 peut également s'appliquer aux systèmes de levage à charge suspendue ayant un comportement linéaire, comme méthode alternative à la méthode des états limites utilisant les facteurs partiels de sécurité, objet de la présente norme.

Dans la mesure où les structures des appareils de levage à charge suspendue sont fondamentalement à charge dynamique, seule s'applique la théorie linéaire de l'élasticité et seule est autorisée la plasticité locale limitée. L'utilisation de

Dvigala (žerjavi) - Konstrukcija, splošno – 3-1. del: Mejna stanja in dokaz varnosti jeklene nosilne konstrukcije

General Information

- Status

- Withdrawn

- Publication Date

- 14-Dec-2004

- Withdrawal Date

- 27-Mar-2012

- Technical Committee

- CEN/TC 147 - Cranes - Safety

- Drafting Committee

- CEN/TC 147/WG 2 - Design - General

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 28-Mar-2012

- Completion Date

- 28-Mar-2012

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 27-Jun-2012

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-Dec-2008

Frequently Asked Questions

CEN/TS 13001-3-1:2004 is a technical specification published by the European Committee for Standardization (CEN). Its full title is "Cranes - General design - Part 3-1: Limit states and proof of competence of steel structures". This standard covers: This European Standard is to be used together with Part 1 and Part 2 and as such they specify general conditions, requirements and methods to prevent mechanical hazards of cranes by design and theoretical verification. NOTE Specific requirements for particular types of crane are given in the appropriate European Standard for the particular crane type. The following is a list of significant hazardous situations and hazardous events that could result in risks to persons during normal use and foreseeable misuse. Clauses 4 to 8 of this standard are necessary to reduce or eliminate the risks associated with the following hazards: a) Exceeding the limits of strength (yield, ultimate, fatigue); b) Exceeding temperature limits of material or components; c) Elastic instability of the crane or its parts (buckling, bulging). This European Standard is applicable to cranes which are manufactured after the date of approval by CEN of this standard and serves as reference base for the European Standards for particular crane types. NOTE prCEN/TS 13001-3-1 deals only with limit state method according to prEN 13001-1. As an alternative to the herein presented limit state method using partial safety factors, the allowable stress method using a global safety factor according to prEN 13001-1 and prEN 13001-2 may also be applied for special crane systems with linear behaviour. As crane structures are basically dynamically loaded only the linear theory of elasticity is applicable and only limited local plasticity is allowed. The use of the theory of plasticity for calculation of ultimate load bearing capacity is not allowed.

This European Standard is to be used together with Part 1 and Part 2 and as such they specify general conditions, requirements and methods to prevent mechanical hazards of cranes by design and theoretical verification. NOTE Specific requirements for particular types of crane are given in the appropriate European Standard for the particular crane type. The following is a list of significant hazardous situations and hazardous events that could result in risks to persons during normal use and foreseeable misuse. Clauses 4 to 8 of this standard are necessary to reduce or eliminate the risks associated with the following hazards: a) Exceeding the limits of strength (yield, ultimate, fatigue); b) Exceeding temperature limits of material or components; c) Elastic instability of the crane or its parts (buckling, bulging). This European Standard is applicable to cranes which are manufactured after the date of approval by CEN of this standard and serves as reference base for the European Standards for particular crane types. NOTE prCEN/TS 13001-3-1 deals only with limit state method according to prEN 13001-1. As an alternative to the herein presented limit state method using partial safety factors, the allowable stress method using a global safety factor according to prEN 13001-1 and prEN 13001-2 may also be applied for special crane systems with linear behaviour. As crane structures are basically dynamically loaded only the linear theory of elasticity is applicable and only limited local plasticity is allowed. The use of the theory of plasticity for calculation of ultimate load bearing capacity is not allowed.

CEN/TS 13001-3-1:2004 is classified under the following ICS (International Classification for Standards) categories: 53.020.20 - Cranes. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TS 13001-3-1:2004 has the following relationships with other standards: It is inter standard links to EN 13001-3-1:2012, EN 13852-1:2013, EN 81-43:2009, EN 13135-2:2004+A1:2010, CEN/TS 13001-3-1:2004/AC:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TS 13001-3-1:2004 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/BC/CEN/91/1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

CEN/TS 13001-3-1:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2005

Dvigala (žerjavi) - Konstrukcija, splošno – 3-1. del: Mejna stanja in dokaz varnosti

jeklene nosilne konstrukcije

Cranes - General design - Part 3-1: Limit states and proof of competence of steel

structures

Krane - Konstruktion allgemein - Teil 3-1: Grenzzustände und Sicherheitsnachweis von

Stahltragwerken

Appareils de levage a charge suspendue - Conception générale - Partie 3-1: Etats limites

et vérification d'aptitude des structures en acier

Ta slovenski standard je istoveten z: CEN/TS 13001-3-1:2004

ICS:

53.020.20 Dvigala Cranes

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

TECHNICAL SPECIFICATION

CEN/TS 13001-3-1

SPÉCIFICATION TECHNIQUE

TECHNISCHE SPEZIFIKATION

December 2004

ICS 53.020.20

English version

Cranes - General design - Part 3-1: Limit states and proof of

competence of steel structures

Appareils de levage à charge suspendue - Conception Krane - Konstruktion allgemein - Teil 3-1: Grenzzustände

générale - Partie 3-1: Etats limites et vérification d'aptitude und Sicherheitsnachweis von Stahltragwerken

des structures métalliques

This Technical Specification (CEN/TS) was approved by CEN on 25 November 2003 for provisional application.

The period of validity of this CEN/TS is limited initially to three years. After two years the members of CEN will be requested to submit their

comments, particularly on the question whether the CEN/TS can be converted into a European Standard.

CEN members are required to announce the existence of this CEN/TS in the same way as for an EN and to make the CEN/TS available

promptly at national level in an appropriate form. It is permissible to keep conflicting national standards in force (in parallel to the CEN/TS)

until the final decision about the possible conversion of the CEN/TS into an EN is reached.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2004 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TS 13001-3-1:2004: E

worldwide for CEN national Members.

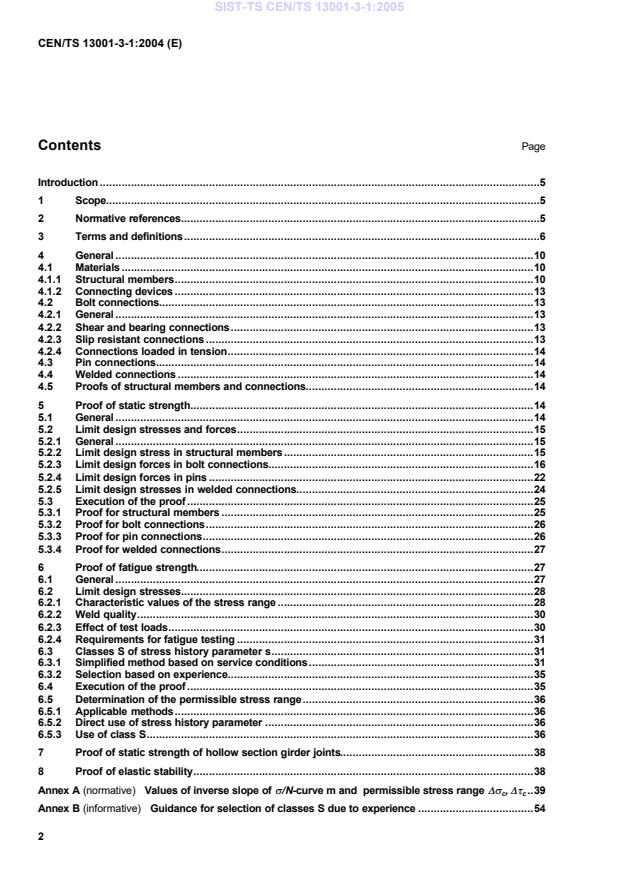

Contents Page

Introduction .5

1 Scope.5

2 Normative references.5

3 Terms and definitions.6

4 General .10

4.1 Materials .10

4.1.1 Structural members.10

4.1.2 Connecting devices .13

4.2 Bolt connections.13

4.2.1 General .13

4.2.2 Shear and bearing connections.13

4.2.3 Slip resistant connections .13

4.2.4 Connections loaded in tension.14

4.3 Pin connections.14

4.4 Welded connections .14

4.5 Proofs of structural members and connections.14

5 Proof of static strength.14

5.1 General .14

5.2 Limit design stresses and forces.15

5.2.1 General .15

5.2.2 Limit design stress in structural members.15

5.2.3 Limit design forces in bolt connections.16

5.2.4 Limit design forces in pins .22

5.2.5 Limit design stresses in welded connections.24

5.3 Execution of the proof .25

5.3.1 Proof for structural members .25

5.3.2 Proof for bolt connections.26

5.3.3 Proof for pin connections.26

5.3.4 Proof for welded connections.27

6 Proof of fatigue strength.27

6.1 General .27

6.2 Limit design stresses.28

6.2.1 Characteristic values of the stress range .28

6.2.2 Weld quality.30

6.2.3 Effect of test loads.30

6.2.4 Requirements for fatigue testing .31

6.3 Classes S of stress history parameter s.31

6.3.1 Simplified method based on service conditions.31

6.3.2 Selection based on experience.35

6.4 Execution of the proof .35

6.5 Determination of the permissible stress range.36

6.5.1 Applicable methods.36

6.5.2 Direct use of stress history parameter .36

6.5.3 Use of class S.36

7 Proof of static strength of hollow section girder joints.38

8 Proof of elastic stability.38

Annex A (normative) Values of inverse slope of s/N-curve m and permissible stress range Ds , Dt .39

c c

Annex B (informative) Guidance for selection of classes S due to experience .54

Annex C (normative) Calculated values of permissible stress range Ds .55

Rd

Annex D (normative) Design weld stress s and t .57

W,Sd W,Sd

D.1 Butt joint .57

D.2 Fillet weld and groove weld with uniform distributed load.58

D.3 Relevant distribution length under punctiform load .59

Annex E (informative) Hollow Sections .60

Annex F (informative) Selection of a suitable set of crane standards for a given application .71

Annex ZA (informative) Relationship between this European Standard and the Essential Requirements

of EU Directive 98/37/EC .72

Bibliography .73

Foreword

This document (CEN/TS 13000-3.1:2004) has been prepared by Technical Committee CEN/TC 147 “Cranes —

Safety”, the secretariat of which is held by BSI.

This document has been prepared under a mandate given to CEN by the European Commission and the European

Free Trade Association, and supports essential requirements of EU Directive 98/37/EC, amended by 98/79/EC.

According to the CEN/CENELEC Internal Regulations, the national standards organisations of the following

countries are bound to announce this Technical Specification: Austria, Belgium, Cyprus, Czech Republic, Denmark,

Estonia, Finland, France, Germany, Greece, Hungary Iceland, Ireland, Italy, Latavia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

This European Standard is one Part of EN 13001. The other parts are as follows:

Part 1: General principles and requirements

Part 2: Load actions

The annexes A, C and D are normative. The annexes B, E and F are informative.

Introduction

This European Standard has been prepared to be a harmonised standard to provide one means for the mechanical

design and theoretical verification of cranes to conform with the essential health and safety requirements of the

Machinery Directive, as amended. This standard also establishes interfaces between the user (purchaser) and the

designer, as well as between the designer and the component manufacturer, in order to form a basis for selecting

cranes and components.

This European Standard is a type C standard as stated in EN 1070.

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are

indicated in the scope of this document.

When provisions of this type C standard are different from those which are stated in type A or B standards, the

provisions of this type C standard take precedence over the provisions of the other standards, for machines that

have been designed and built according to the provisions of this type C standard.

The machinery concerned and the extent to which hazards are covered are indicated in the scope of this standard.

1 Scope

This European Standard is to be used together with Part 1 and Part 2 and as such they specify general conditions,

requirements and methods to prevent mechanical hazards of cranes by design and theoretical verification.

NOTE Specific requirements for particular types of crane are given in the appropriate European Standard for the particular

crane type.

The following is a list of significant hazardous situations and hazardous events that could result in risks to persons

during normal use and foreseeable misuse. Clauses 4 to 8 of this standard are necessary to reduce or eliminate

the risks associated with the following hazards:

a) Exceeding the limits of strength (yield, ultimate, fatigue);

b) Exceeding temperature limits of material or components;

c) Elastic instability of the crane or its parts (buckling, bulging).

This European Standard is applicable to cranes which are manufactured after the date of approval by CEN of this

standard and serves as reference base for the European Standards for particular crane types.

NOTE prCEN/TS 13001-3-1 deals only with limit state method according to EN 13001-1.

As an alternative to the herein presented limit state method using partial safety factors, the allowable stress method

using a global safety factor according to Part 1 and Part 2 may also be applied for special crane systems with linear

behaviour.

As crane structures are basically dynamically loaded only the linear theory of elasticity is applicable and only limited

local plasticity is allowed. The use of the theory of plasticity for calculation of ultimate load bearing capacity is not

allowed.

2 Normative references

This European Standard incorporates by dated or undated reference, provisions from other publications. These

normative references are cited at the appropriate places in the text, and the publications are listed hereafter. For

dated references, subsequent amendments to or revisions of, any of these publications apply to this European

Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the

publication referred to applies (including amendments).

EN 1070:1998, Safety of machinery — Terminology.

EN 1990-1:2002, Eurocode – Basic of structural design

EN 1993-1-1:1992: Eurocode 3: Design of steel structures — Part 1-1: General rules and rules for buildings.

EN 10025:1990/A1:1993, Hot rolled products of non-alloy structural steels — Technical delivery conditions

(includes amendment A1:1993).

EN 10045-1:1989, Charpy impact test on metallic material — Part 1: Test method.

EN 10113-1:1993, Hot-rolled products in weldable fine grain structural steels — Part 1: General delivery conditions.

EN 10113-2:1993, Hot-rolled products in weldable fine grain structural steels — Part 2: Delivery conditions for

normalized/normalized rolled steels.

EN 10113-3:1993, Hot-rolled products in weldable fine grain structural steels — Part 3: Delivery conditions for

thermomechanical rolled steels.

EN 10137-2:1995, Plates and wide flats made of high yield strength structural steels in the quenched and tempered

or precipitation hardened conditions — Part 2: Delivery conditions for quenched and tempered steels.

EN 10149-1:1995, Hot-rolled flat products made of high yield strength steels for cold forming — Part 1: General

delivery conditions.

EN 10149-2:1995, Hot-rolled flat products made of high yield strength steels for cold forming — Part 2: Delivery

conditions for thermomechanically rolled steels.

EN 10149-3:1995, Hot-rolled flat products made of high yield strength steels for cold forming — Part 3: Delivery

conditions for normalized or normalized rolled steels.

EN 10164:1993, Steel products with improved deformation properties perpendicular to the surface of the product —

Technical delivery conditions.

EN 12345:1996, Welding — Multilingual terms for welding joints with illustrations (trilingual version).

EN 13001-1:2004, Cranes — General Design — Part 1:General principles and requirements.

EN 13001-2:2004, Cranes — General Design — Part 2: Load actions.

EN 22553:1994, Welded, brazed and soldered joints — Symbolic representation on drawings (ISO 2553:1992).

EN 25817:1992, Arc-welded joints in steel — Guidance on quality levels for imperfections (ISO 5817:1992).

EN ISO 898-1:1999, Mechanical properties of fasteners — Part 1: Bolts, screws and studs (ISO 898-1:1999).

EN ISO 9013:2002, Thermal cutting — Classification of thermal cuts — Geometrical specification and quality

tolerances (ISO 9013:2002).

EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic

terminology, methodology (ISO 12100-1:2003).

EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical

principles and specifications (ISO 12100-2:2003).

ISO 286-2:1990, ISO system of limits and fits — Part 2: Tables of standard tolerance grades and limit deviations for

holes and shafts.

ISO 4306-1:1990, Cranes — Vocabulary — Part 1: General.

3 Terms and definitions

3.1

Terms and definitions

For the purposes of this European Standard, the terms and definitions given in EN 292-1, EN 292-2 and EN 1070

and the basic list of definitions as provided in EN 1990-1 apply. For the definitions of loads, clause 6 of

ISO 4306-1:1990 applies.

3.2

Symbols and abbreviations

The symbols and abbreviations used in this Part of the EN 13001 are given in Table 1.

Table 1 — Symbols and abbrevations

Symbols,

Description

abbreviations

A cross section

A stress area of a bolt

S

a relevant weld thickness

r

D , D outer, inner diameter of hollow pin

o i

d diameter (shank of bolt, pin)

d diameter of hole

o

e , e distances

1 2

F tensile force in bolt

b

F limit force

d

F characteristic value (force)

K

F preloading force in bolt

p

F limit design force

Rd

F external force (on bolted connection)

t

F limit design bearing force

b, Rd

F ; F design bearing force

b, Sd bi, Sd

F design preloading force

p, d

F limit design slip force per bolt and friction interface

s, Rd

F limit design tensile force in bolt

t, Rd

F limit design shear force per bolt/pin and shear plane

v, Rd

F design shear force per bolt/pin and shear plane

v, Sd

F acting normal/shear force

s,t

f limit stress

d

f characteristic value (stress)

K

f limit design stress

Rd

Table 1 (continued)

Symbols,

Description

abbreviations

f ultimate strength of material

u

f ultimate strength of bolts

ub

f limit design weld stress

w, Rd

f yield point of material

y

f yield point of bolts

yb

f yield point (nominal value) of material or member

yk

f yield point of pins

yp

G mass of the moving crane parts during a representative working cycle

t

h distance between weld and contact area of acting load

K stiffness (slope) of bolt

b

K stiffness (slope) of flanges

c

k* specific spectrum ratio factor

k stress spectrum factor based on m of the detail under consideration

(m)

k stress spectrum factor based on m = 3

(m=3)

l relevant weld length

r

l weld length

W

M limit design bending moment

Rd

M design bending moment

Sd

m

inverse slope of s/N-curve

NC notch class

extreme values of stresses

min s, max s

P probability of survival

S

p , p distances

1 2

Q mass of the maximum hoist load

q impact toughness parameter

R design resistance

d

r radius of wheel

S design strain

d

s(m) stress history parameter

T temperature

t thickness

W elastic section modulus

el

characteristic factor for bearing connection

a

characteristic factor for limit weld stress

a

w

general resistance coefficient

g

m

fatigue strength specific resistance factor

g

Mf

Table 1 (concluded)

Symbols,

Description

abbreviations

partial safety factor

g

p

resulting resistance coefficient

g

R

specific resistance factor

g

S

resulting resistance coefficient of bolt

g

Rb

g

specific resistance factor of bolt

sb

g resulting resistance coefficient of members

Rm

g specific resistance factor of members

sm

g resulting resistance coefficient of pins

Rp

g specific resistance factor of pins

sp

g resulting resistance coefficient of slip-resistance connection

Rs

g specific resistance factor of slip-resistance connection

ss

g resulting resistance coefficient of welding connection

Rw

g specfic resistance factor of welding connection

sw

f dynamic factor

k spread angle

l width of contact area in weld direction

d elongation from preloading

p

DF additional force

b

Dd additional elongation

µ slip factor

Ds characteristic value of stress range (normal stress)

c

Dt characteristic value of stress range (shear stress)

c

s design stress (normal)

Sd

t design stress (shear)

Sd

s design weld stress (normal)

w, Sd

t

design weld stress (shear)

w, Sd

Ds permissible (limit) stress range (normal)

Rd

Ds permissible stress range for k* = 1

Rd,1

Dt permissible (limit) stress range (shear)

Rd

Ds design stress range (normal)

Sd

Dt design stress range (shear)

Sd

4 General

4.1 Materials

4.1.1 Structural members

European Standards specify materials and specific values. This standard gives a preferred selection.

For structural members, steel according to following European Standards should be used:

¾ Non-alloy structural steels EN 10025.

¾ Weldable fine grain structural steels in conditions:

¾ normalised (N) EN 10113-2;

¾ thermomechanical (M) EN 10113-3.

¾ High yield strength structural steels in the quenched and tempered condition EN 10137-2.

¾ High yield strength steels for cold forming in conditions:

¾ thermomechanical (M) EN 10149-2;

¾ normalised (N) EN 10149-3.

Table 2 shows specific values for the nominal value of strength f , f and limit design stress f (see 5.2). For more

u y Rd

information see the specific European Standard.

Grades and qualities other than those mentioned in the above standards and in Table 2 can be used if the

mechanical properties and the chemical composition are guaranteed by the manufacturer and conform to the

relevant European Standard. If necessary, the weldability shall be demonstrated by the steel manufacturer.

When selecting grade and quality of the steel for tensile members, the sum of impact toughness parameters q shall

i

be taken into account. Table 3 gives the impact toughness parameters q for various influences. Table 4 gives the

i

required steel quality and impact energy/test temperature in dependence of Sq. Grades and qualities of steel other

i

than mentioned in Table 4 may be used, if the steel manufacturer guarantees and certifies an impact energy/test

temperature, tested according to EN 10045-1.

Table 2 — Specific values of steels for structural members

Limit design stress

Nominal strength

for g =1,1

Rm

Thickness t

Steel Standard

f f

y u

(mm)

f , normal f , shear

Rd Rd

yield ultimate 2 2

2 2 (N/mm ) (N/mm )

(N/mm ) (N/mm )

t£16 235 214 123

225 205 118

16

S235 340

215 195 113

40

195 177 102

100

275 250 144

t£16

265 241 139

16

255 232 134

40

S275 430

245 223 129

63

EN 10025

235 214 123

80

225 205 118

100

t£16 355 323 186

345 314 181

16

335 305 176

40

S355 490

325 296 171

63

315 287 166

80

295 268 155

100

t<16 355 323 186

345 314 181

16

335 305 176

40

S355 450

325 295 171

63

315 286 165

80

295 268 155

100

t<16 420 382 220

EN 10113-2

16

(N)

390 355 205

40

S420

370 336 194

63

EN 10113-3

360 327 189

80

(M)

340 309 178

100

t<16

460 418 241

440 400 231

16

430 391 226

S460 40

410 373 215

63

400 364 210

80

3

S460 550

440 400 231

50

500 455 262

3

S500 590

480 436 252

50

3

S550 640

530 482 278

50

EN 10137-2 3

S620

580 527 304

50

690 627 362

3

S690

650 591 341

50

3

S890

830 880 755 436

50

960 873 504

S960 3

Table 2 (concluded)

Limit design stress

Nominal strength

for g =1,1

Rm

Thickness

Steel Standard

f f

y u

t (mm)

f , normal f , shear

Rd Rd

yield ultimate

2 2

(N/mm ) (N/mm )

2 2

(N/mm ) (N/mm )

S315 315 390 286 165

S355 355 430 323 186

S420 420 480 382 220

S460 (M) 460 520 418 241

all t

500 455 262

EN 10149–2

S500 (M) 550

(M)

550 500 289

S550 (M) 600

EN 10149-3

(N)

S600 (M) 600 650 545 315

t£8 650 591 341

S650 (M) 700

t>8 630 573 331

t£8 700 636 367

S700 (M) 750

t>8 680 618 357

Table 3 — Impact toughness parameters q

i

i Influence q

i

0 £ T

-20 £ T < 0 1

1 Temperature T (°C)

-40 £ T < -20 2

-50 £ T < -40 4

f £ 300 0

y

300 < f £ 460 1

y

2 Yield point f (N/mm ) 460 < f £ 700 2

y y

700

y

1 000

y

Material thickness t (mm) t £ 10 0

Equivalent thickness t for solid bars: 10 < t £ 20 1

20 < t £ 50 2

50 < t £ 100 3

d b b

t = for <1,8 : t =

t > 100 4

1,8 1,8

h

Ds > 125 0

c

80 < Ds £ 125 1

c

Stress concentration and notch class Ds

c

(N/mm ) (see annex A and annex E)

56< Ds £ 80 2

c

Ds £ 56 3

c

Table 4 — Impact toughness requirement and corresponding steel quality for åq

i

åq £ 3 4 £ åq £ 6 7 £ åq £ 9 åq ³ 10

i i i i

Impact energy/ test

temperature 27 J / +20°C 27 J / 0°C 27 J / -20°C 27 J / -40°C

requirement

EN 10025 JR J0 J2 a)

EN 10113 N, M N, M N, M NL, ML

EN 10137-2 Q Q Q QL

EN 10149 NC, MC NC, MC NC, MC a)

a)

May be used if the steel manufacturer guarantees and certifies an impact energy/test temperature of at least 27 J at

–40 °C, tested according to EN 10045-1.

4.1.2 Connecting devices

For bolt connections bolts of the property classes 4.6, 5.6, 8.8, 10.9 or 12.9 according to EN ISO 898-1 shall be

used. Nominal values of the strengths:

Table 5 — Property classes

Property class 4.6 5.6 8.8 10.9 12.9

f (N/mm ) 240 300 640 900 1 080

yb

f (N/mm ) 400 500 800 1 000 1 200

ub

4.2 Bolt connections

4.2.1 General

For the purpose of this standard bolt connections are specified as connections, where

¾ bolts are tightened and thus compress the joint surfaces together;

¾ the joint surfaces are secured against rotation (e. g. by using multiple bolts).

4.2.2 Shear and bearing connections

Connections with fitted bolts, where

¾ the loads act perpendicular to the bolt axis and cause shear and bearing stresses in the bolts;

¾ clearance between bolt and hole shall be according to ISO 286-2 tolerances h13 and H11;

¾ at maximum 10 % of the clamping length may be covered by the threaded part of the bolt;

¾ special surface treatment of the contact surfaces is not required.

4.2.3 Slip resistant connections

Connections with high strength bolts of property classes 8.8, 10.9 or 12.9, where

¾ the loads are transmitted by friction between the joint surfaces;

¾ bolts are tightened by a controlled method to the full preloading state;

¾ the surface condition of the contact surfaces shall be specified and taken into account accordingly.

4.2.4 Connections loaded in tension

Connections with high strength bolts of property classes 8.8, 10.9 or 12.9, where

¾ the loads act in the direction of the bolt axis and cause axial stresses in the bolts;

¾ bolts are tightened by a controlled method to the full preloading state;

¾ fatigue assessment of the bolts shall be done considering the structural features of the joint, e. g. stiffness of

the connected parts and the leverage action caused by the joint geometry;

¾ an even contact over the whole intended contact area of the joint shall be ensured.

4.3 Pin connections

Pin connections are regarded as connections that allow turning of the connected parts.

4.4 Welded connections

Terms for welded joints shall be as given in EN 12345. Symbolic representation on drawings shall be according to

EN 22553.

4.5 Proofs of structural members and connections

It has to be proven that the strains S do not exceed the resistances R :

d d

S £ R (1)

d d

The strains S shall be determined by applying the loads, load combinations and partial safety factors according

d

Table 10 of EN 13001-2.

In the following clauses, the resistances R are presented as limit stresses f or limit forces F .

d d d

For the ultimate limit state, the following proofs shall be delivered:

¾ proof of strength of structural members and connections under quasi-static stress according to 5;

¾ proof of fatigue strength according to 6;

¾ proof of strength of hollow section girder joints under quasi-static stress according to 7;

¾ proof of elastic stability of structural members and special elements according to 8.

5 Proof of static strength

5.1 General

The proof of strength under quasi-static stress protects against excessive deformations due to yielding of the

material or sliding of friction-grip connections as well as against static rupture of structural members or connections.

The proof shall be delivered for structural members and connections taking into account the most unfavourable

load effects from the load combinations A, B or C according to Table 10 of EN 13001-2: and applying the

resistances according to 5.2.

5.2 Limit design stresses and forces

5.2.1 General

The limit design stresses and forces shall be calculated by:

Limit design stresses f = function ( f ,g ) or

Rd k R

(2)

Limit design forces F = function ( F ,g )

Rd k R

where

f or F are characteristic values (or nominal values)

k k

g is the resulting resistance coefficient g =g ×g

R R m s

g is the resistance coefficient g =1,1 (see Table 10 of EN 13001-2)

m m

g is the general specific resistance coefficient for special parts of this standard

s

NOTE f and F are equivalent to R / g in Figure 2 of EN 13001-1.

Rd Rd m

5.2.2 Limit design stress in structural members

The limit design stress f , used for the design of structural members, shall be calculated by:

Rd

f

yk

f = for normal stresses (3)

Rd

g

Rm

f

yk

f = for shear stresses (4)

Rd

g

Rm

with g = g ×g

Rm m sm

where

f is the nominal value of the yield point of the material (see Table 2)

yk

g is the specific resistance coefficient for material as follows:

sm

For non-rolled material

g =1,0

sm

For rolled materials (e. g. plates and profiles):

g = 1,0 for stresses in the plane of rolling

sm

g = 1,0 for compressive and shear stresses

sm

For tensile stresses perpendicular to the plane of rolling (see Figure 1):

g = 1,0 for material in quality classes Z25 or Z35 according to EN 10164

sm

g = 1,16 for material in quality class Z15 according to EN 10164

sm

g = 1,34 without quality classification

sm

Figure 1 — Tensile load perpendicular to plane of rolling

Hence follow the limit design stresses, which are dependent on the material and the kind of stressing which are

given in Table 2.

5.2.3 Limit design forces in bolt connections

5.2.3.1 Shear and bearing connections

The resistance of a connection shall be determined by applying the limit forces of the individual connecting devices.

The limit design shear force F per bolt and per shear plane shall be calculated by:

v,Rd

f × A

yb

=

F (5)

,

v Rd

g × 3

Rb

with g =g ×g

R m sb

b

where

f is the yield point (nominal value) of the bolt material

yb

A is the cross-section of the bolt shank at the shear plane

g is the specific resistance factor for bolt connections

sb

g = 1,0 for multiple shear plane connections

sb

g = 1,3 for single shear plane connections

sb

See Table 6 for limit design shear forces as an example.

Table 6 — Limit design shear force F per fitted bolt and per shear plane for multiple shear plane

v,Rd

connections

F (kN)

v,Rd

Shank resp.

Fitted bolt Hole diameter Fitted bolt material

hole section

for g = 1,1

Rb

(mm) (mm ) 4.6 5.6 8.8 10.9 12.9

M12 13 133 16,7 20,9 44,6 62,8 75,4

M16 17 227 28,6 35,7 76,2 107,2 128,6

M20 21 346 43,5 54,4 116,2 163,2 196,1

M22 23 415 52,2 65,3 139,4 196,0 235,2

M24 25 491 61,8 77,3 164,9 231,9 278,3

M27 28 616 77,6 97,0 206,9 291,0 349,2

M30 31 755 95,1 111,8 253,6 356,6 428,0

The limit design bearing force F per bolt may be calculated by:

b,Rd

a × f × d ×t

y

F = (6)

b,Rd

g

Rb

with g =g ×g

R m sb

b

where

e

3×d

e ³ 2,0 d

1 o

p 1

- e ³ 1,5 d (7)

2 o

a = Min

3×d 4

p ³ 3,0 d

1 o

p ³ 3,0 d

f 2 o

ub

f

u

1.0

Figure 2 — Illustration for formula (7)

f is the ultimate strength (nominal value) of the bolt (Table 5)

ub

f is the ultimate strength (nominal value) of the basic material (Table 2)

u

f is the yield point (nominal value) of the basic material (Table 2)

y

d is the shank diameter of the bolt

t is the minimum of thicknesses of the basic material

g is the specific resistance factor for bolt connections

sb

g = 0,7 for multiple shear plane connections

sb

g = 0,9 for single shear plane connections

sb

5.2.3.2 Slip-resistant connections

The resistance of a connection shall be determined by applying the limit forces of the individual connecting devices.

For slip-resistant connections the limit design slip force F per bolt and per friction interface shall be calculated

s,Rd

by:

m × (F - F )

p,d t

F = (8)

s,Rd

g

Rs

with g =g ×g

Rs m ss

where:

m is the slip factor

m = 0,50 for surfaces

¾ blasted metallic bright with steel grit or sand, no unevennesses;

¾ blasted with steel grit or sand and aluminised;

¾ blasted with steel grit or sand and metallised with a product basing on zinc that

causes a friction coefficient of min. 0,5

m = 0,40 for surfaces

¾ blasted with steel grit or sand and alkali-zinc-silicate coating of 50 mm to 80 mm

thickness

m = 0,30 for surfaces

¾ cleaned metallic bright with wire brush or scarfing

m = 0,20 for surfaces

¾ cleaned of loose rust, oil and dirt

F is the design preloading force.

p,d

F is an external tensile force in direction of the axis of the bolt (see Figure 3)

t

It shall be ensured that the used preloading force is greater than or equal to the design

preloading force.

g is the specific resistance factor for slip-resistant connections;

ss

g =1,14

ss

See Table 7 for limit design slip forces using for example a design preloading force of

F = 0,7× f × A ,

p,d yb s

where

f is the yield point (nominal value) of the bolt material (Table 5)

yb

A is the stress area of the bolt.

s

prCEN/TS 13001-3-1:2003 (E)

Table 7 — Limit design slip force F per bolt and per friction interface using a design preloading force F =0.7× f × A

S,Rd

p,d yb s

Bolt stress Design preloading

Limit design slip force F (kN)

s,Rd

area force F (kN)

p,d

Bolt material

A Bolt material

S

(mm ) 8.8 10.9 12.9

Slip factor : Slip factor : Slip factor :

8.8 10.9 12.9 0.50 0.40 0.30 0.20 0.50 0.40 0.30 0.20 0.50 0.40 0.30 0.20

M12 84,3 37,8 53,1 63,7 15,1 12,1 9,1 6,0 21,2 17,0 12,7 8,5 25,5 20,4 15,3 10,2

M16 157,0 70,3 98,9 119,0 28,1 22,5 16,9 11,2 39,6 31,6 23,7 15,8 47,6 38,1 28,6 19,0

M20 245,0 110,0 154,0 185,0 44,0 35,2 26,4 17,6 61,6 49,3 37,0 24,6 74,0 59,2 44,4 29,6

M22 303,0 136,0 191,0 229,0 54,4 43,5 32,6 21,8 76,4 61,1 45,8 30,6 91,6 73,3 55,0 36,6

M24 353,0 158,0 222,0 267,0 63,2 50,6 37,9 25,3 88,8 71,0 53,3 35,5 107,0 85,4 64,1 42,7

M27 459,0 206,0 289,0 347,0 82,4 65,9 49,4 33,0 116,0 92,5 69,4 46,2 139,0 111,0 83,3 55,5

M30 561,0 251,0 353,0 424,0 100,0 80,3 60,2 40,2 141,0 113,0 84,7 56,5 170,0 136,0 102,0 67,8

M36 817,0 366,0 515,0 618,0 146,0 117,0 87,8 58,6 206,0 165,0 124,0 82,4 247,0 198,0 148,0 98,9

CEN/TS 13001-3.1:2004 (E)

5.2.3.3 Connections loaded in tension

The resistance of a connection shall be determined by applying the limit forces of the individual connecting

devices.

In principle the proof of competence has to take into account the stiffnesses of the bolt and the flanges to be

connected (see Figure 3).

F Preloading force in bolt

p

d Bolt elongation from preloading

p

F External force

t

Dd: Additional elongation

F Tensile force in bolt

b

DF additional force in bolt

b

Slope K Stiffness of bolt

b

Slope K Stiffness of flanges

c

Figure 3 — Force-elongation-diagram

For simplification the limit design tensile force per bolt F may be calculated by:

t,Rd

F

p,d

F = (9)

t,Rd

g

Rb

with g = g × g

Rb m sb

where

F is the design preloading force. It shall be ensured that the used preloading force is

p,d

greater than or equal to the design preloading force

g is the specific resistance factor for connections loaded in tension

sb

g = 1,0

sb

See Table 8 for limit design tensile forces according to formula (9) using for example a design preloading

force of

F =0,7× f × A

p,d yb s

where

CEN/TS 13001-3.1:2004 (E)

f is the yield point (nominal value) of the bolt material (Table 5)

yb

A is the stress area of the bolt.

s

Table 8 — Limit design tensile force F per bolt in direction of the bolt axis, using a design

t,Rd

preloading force F =0,7× f × A

p,d yb s

Limit design tensile force

per bolt

Design preloading

stress

area

F (kN)

force F (kN) t,Rd

p,d

Bolt

A

for g = 1.1

S

Bolt material Rb

(mm )

Bolt material

8.8 10.9 12.9 8.8 10.9 12.9

M12 84,3 37,8 53,1 63,7 34,3 48,2 57,9

M16 157,0 70,3 98,9 119,0 63,9 88,9 108,1

M20 245,0 110,0 154,0 185,0 100,0 140,0 168,1

M22 303,0 136,0 191,0 229,0 123,6 173,6 208,1

M24 353,0 158,0 222,0 267,0 143,9 201,8 242,7

M27 459,0 206,0 289,0 347,0 187,2 262,7 315,4

M30 561,0 251,0 353,0 424,0 228,1 320,9 385,4

M36 817,0 366,0 515,0 618,0 332,7 468,1 561,8

5.2.4 Limit design forces in pins

The pin of a pin connection shall be designed taking into account bending, shearing and bearing. Therefore

the following simplified system may be assumed:

For pins the following limit design loads shall be taken into account:

W × f

el yp

¾ Limit design bending moment M = (10)

Rd

g

Rp

with g =g ×g

Rp m sp

where

W is the elastic section modulus of the pin

el

f is the yield point (nominal value) of the pin material

yp

g is the specific resistance factor for pin connections bending moment g = 1,0

sp

sp

A× f

yp

¾ Limit design shear force per shear plane for pins F = × (11)

v,Rd

u

3 ×g

Rp

CEN/TS 13001-3.1:2004 (E)

with g =g ×g

Rp m sp

where

u u = for solid pins

4 1+ v + v

u = × for hollow pins

3 1+ v

where

D

i

n = ,

D

O

D is the inner diameter of pin

i

D is the outer diameter of pin

O

A is the cross-section of the pin

g is the specific resistance factor for pin connections shear force

sp

g = 1,0 for multiple shear plane connections

sp

g = 1,3 for single shear plane connections

sp

a × d × t × f

y

¾ Limit design bearing force F = (12)

b,Rd

g

Rp

with g =g ×g

Rp m sp

where

f

ì

yp

ï

f

y

ï

ï

a=Min

í

ï

1,0

ï

ï

î

CEN/TS 13001-3.1:2004 (E)

Figure 4 — Pin connections

f is the yield point (nominal value) of basic material

y

d is the diameter of the pin

t is the minimum of thickness of the basic material

g is the specific resistance factor for pin connections bearing force

sp

g = 0,7 for multiple shear plane connections

sp

g = 0,9 for single shear plane connections

sp

In case of significant movement between pin and bearing the limit bearing force shall be reduced in order to

reduce wear.

5.2.5 Limit design stresses in welded connections

The limit design weld stress f used for the design of a welded connection depends on:

w,Rd

¾ the parent metal to be welded;

¾ the type of the weld;

¾ the type of stress;

¾ the weld quality;

¾ the kind of welding process.

CEN/TS 13001-3.1:2004 (E)

The limit design weld stress f shall be calculated by:

w,Rd

× f

a

w

yk

f = (13)

w,Rd

g

Rw

with g =g ×g

Rw m sw

where

a is a factor given in Table 9 in dependence on the type of weld, the type of stress and the material

w

f is the minimal nominal value of the yield points of the parent and weld consumable materials in the

yk

weld joint

g is the specific resistance factor for welded connections

sw

g = 1,0

sw

Table 9 — Factor a for limit weld stress

w

a

w

Direction of

Penetration Type of stress

f < 690 690 £ f < 960 f ³ 960

yk

yk yk

stress

(N/mm²)

(N/mm²) (N/mm²)

Weld with full Tension 1,0 1,0 0,93

penetration or

Compression 1,0 1,0 0,93

backwelded

Tension 0,7 0,7 0,65

Stress across the Weld without

weld direction full penetration

Compression 0,8 0,8 0,74

Weld

with/without full Shear 1/Ö2 1/Ö3 0,54

penetration

Tension/

Weld

1,0 1,0 0,93

Stress in weld

Compression

with/without full

direction

penetration

Shear 1/Ö3 1/Ö3 0,54

5.3 Execution of the proof

5.3.1 Proof for structural members

For the structural member to be designed it shall be proven that:

s £ f and t £ f (14)

Sd Rd Sd Rd

where

t , s are the design stresses

Sd Sd

f is the corresponding limit design stress according to 5.2.2.

Rd

CEN/TS 13001-3.1:2004 (E)

In case of plane states of stresses it shall additionally be proven that:

æ s ö æs ö s ×s

æ ö

t

Sd ,x Sd, y Sd,x Sd, y

Sd

ç ÷ ç ÷

ç ÷

+ - + £ 1 (15)

ç ÷

ç ÷ ç ÷

f f f × f f

Rd ,x Rd ,y Rd,x Rd ,y Rd

è ø è ø

è ø

where

x, y indicate the orthogonal directions of stresses

Spatial states of stresses may be reduced to the most unfavourable plane state of stress.

5.3.2 Proof for bolt connections

For the most unfavourably loaded element of a connection it shall be proven that:

F £ F (16)

Sd Rd

where

F is the design force of the element

Sd

F is the limit design force according to 5.2.3, in dependence on the type of the connection

Rd

and its type of stress, i. e.

limit design shear force F

v,Rd

limit design bearing force F

b,Rd

limit design slip force F

s,Rd

limit design tensile force F

t,Rd

In particular for connections loaded in tension (see 5.2.3.3) the tensile force in the bolt F shall always satisfy:

b

f × A

yb S

F £ (17)

b

g

m

5.3.3 Proof for pin connections

For pins, it shall be proven that:

M £ M

Sd Rd

F £ F (18)

v,Sd v,Rd

F £ F

bi,Sd b,Rd

where

M is the design value of the bending moment in the pin

Sd

M is the limit design bending moment according to 5.2.4

Rd

F is the design value of the shear force in the pin

v,Sd

CEN/TS 13001-3.1:2004 (E)

F is the limit design shear f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...