EN 15611:2008

(Main)Railway applications - Braking - Relay valves

Railway applications - Braking - Relay valves

This European Standard is applicable to relay valves designed to control the brake cylinder pressure of compressed air brakes fitted to railway vehicles, in association with an air brake distributor valve or other control device, and in response to a change in vehicle load that is either continuously variable or in two stages i.e. empty - loaded.

Relay valves operating with other pressures, in particular the brake pipe pressure, are not included.

This European Standard specifies the requirements for the design, manufacture and testing of relay valves.

Bahnanwendungen - Bremse - Relaisventile

Diese Europäische Norm gilt für Relaisventile zur Steuerung des Bremszylinderdruckes von Druckluftbremsen

in Eisenbahnfahrzeugen in Zusammenarbeit mit einem Bremssteuerventil oder einem anderen Steuerelement,

abhängig von einer Veränderung der Fahrzeugbeladung, die entweder autokontinuierlich oder

zweistufig, d. h. „leer“ — „beladen“, erfolgt.

Relaisventile, die mit anderen Betriebsdrücken, insbesondere dem Druck in der Hauptluftleitung, arbeiten,

sind hierin nicht erfasst.

In dieser Europäischen Norm werden die Anforderungen für die Konstruktion, die Herstellung und die Prüfung

von Relaisventilen festgelegt.

Applications ferroviaires - Freinage - Relais pneumatiques

La présente Norme européenne s’applique aux relais pneumatiques conçus pour commander la pression du

cylindre des freins à air comprimé montés sur les véhicules ferroviaires, en association avec un distributeur de

freinage à air ou un autre dispositif de commande et en fonction des variations de la charge du véhicule. La

pression commandée peut varier soit continuellement en fonction des variations de la charge, soit par paliers

à 2 niveaux (un niveau pour l’état de charge « vide » et un autre pour l’état de charge « chargé »).

Les relais pneumatiques fonctionnant avec d’autres pressions, notamment la pression de conduite générale,

ne sont pas considérés dans cette norme.

La présente Norme européenne spécifie les exigences relatives à la conception, à la fabrication et aux essais

des relais pneumatiques.

Železniške naprave - Zavore - Ventili za kontrolo tlaka

General Information

- Status

- Withdrawn

- Publication Date

- 18-Nov-2008

- Withdrawal Date

- 05-Oct-2010

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 3/WG 24 - Components

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 06-Oct-2010

- Completion Date

- 06-Oct-2010

Relations

- Effective Date

- 18-Jan-2023

- Referred By

EN 15179:2007 - Railway applications - Braking - Requirements for the brake system of coaches - Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish national quality association.

Sponsored listings

Frequently Asked Questions

EN 15611:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Braking - Relay valves". This standard covers: This European Standard is applicable to relay valves designed to control the brake cylinder pressure of compressed air brakes fitted to railway vehicles, in association with an air brake distributor valve or other control device, and in response to a change in vehicle load that is either continuously variable or in two stages i.e. empty - loaded. Relay valves operating with other pressures, in particular the brake pipe pressure, are not included. This European Standard specifies the requirements for the design, manufacture and testing of relay valves.

This European Standard is applicable to relay valves designed to control the brake cylinder pressure of compressed air brakes fitted to railway vehicles, in association with an air brake distributor valve or other control device, and in response to a change in vehicle load that is either continuously variable or in two stages i.e. empty - loaded. Relay valves operating with other pressures, in particular the brake pipe pressure, are not included. This European Standard specifies the requirements for the design, manufacture and testing of relay valves.

EN 15611:2008 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15611:2008 has the following relationships with other standards: It is inter standard links to EN 15611:2008+A1:2010, EN 15179:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15611:2008 is associated with the following European legislation: EU Directives/Regulations: 2001/16/EC, 2008/57/EC, 96/48/EC; Standardization Mandates: M/275, M/334. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15611:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Železniške naprave - Zavore - Ventili za kontrolo tlakaBahnanwendungen - Bremse - RelaisventileRailway applications - Braking - Relay valves45.040Materiali in deli za železniško tehnikoMaterials and components for railway engineeringICS:Ta slovenski standard je istoveten z:EN 15611:2008SIST EN 15611:2009en,fr01-januar-2009SIST EN 15611:2009SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15611November 2008ICS 45.060.01 English VersionRailway applications - Braking - Relay valvesApplications ferroviaires - Freinage - Relais pneumatiquesBahnanwendungen - Bremse - RelaisventileThis European Standard was approved by CEN on 27 September 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15611:2008: ESIST EN 15611:2009

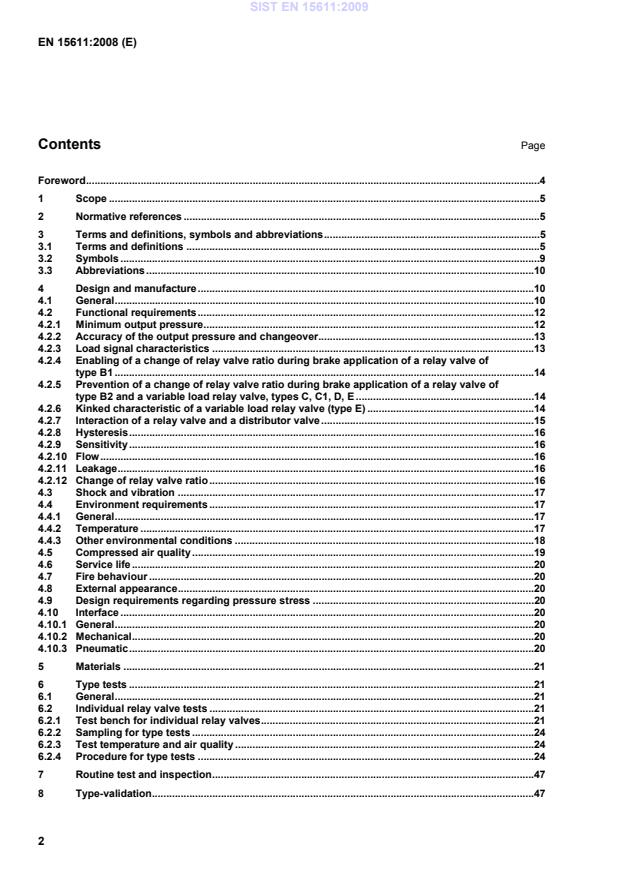

In-service trial.49 A.1 General.49 A.2 Test set-up and sampling.49 A.3 Procedure.49 A.4 Pass/fail criteria.49 Annex B (informative)

Static vehicle and running tests.50 B.1 General.50 B.2 Test recommendations.50 B.2.1 Variable load relay valve.50 B.2.2 Empty/load relay valve.51 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 96/48/EC as modified by Directive 2004/50/EC.52 Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2001/16/EC of the European Parliament and of the Council of 19 March 2001 on the interoperability of the trans-European conventional rail system, as modified by EU Directive 2004/50/EC of 29 April 2004.53 Bibliography.54

NOTE 1 See Figure 1. SIST EN 15611:2009

Key 1 first input pressure 2 second input pressure 3 control signal - continuous load sensing pressure (Lcp), or control signal - empty/load signal pressure (Lsp), or mechanical input (lever) or electrical input 4 auxiliary reservoir pressure, supply pressure (AR) 5 output pressure 6 relay valve Figure 1 — Relay valve, pressures and control signals NOTE 2 The definition of “relay valve” in EN 14478 is specific to a load dependant relay valve. This EN standard considers one or more input pressures in accordance with the diagram in Figure 1. 3.1.2 input pressure control pressure received by the relay valve NOTE Pressure generally considered as being the output pressure from a distributor or a brake control unit; sometimes referred to as pilot pressure or dummy brake cylinder pressure. 3.1.3 output pressure pressure output from the relay valve NOTE Pressure generally considered as being the brake cylinder pressure when the relay valve is used in a variable load braking system. This pressure can also be used as the input pressure to another relay valve. The output pressure can obtain one, two or three fixed levels or it can be changed continuously between a minimum and a maximum or vice versa. 3.1.4 relay valve ratio ratio of the output pressure to input pressure SIST EN 15611:2009

relay valve type D relay valve (type A, B or C) with two (or more) input pressures, controlling a single output pressure SIST EN 15611:2009

3.1.7 sensitivity change of input pressure causing a variation of output pressure, when the change of input pressure is in the same direction, with no overshoot or reversal 3.1.8 initial sensitivity change of input pressure, starting at 0 bar which causes the output pressure to start increasing

NOTE See Figure 2. 3.1.9 sensitivity at reversal change of input pressure causing a variation of output pressure, when the change of input pressure is changing its direction from increasing to decreasing

NOTE See Figure 2. 3.1.10 hysteresis difference in output pressure with the same input pressure, where the input pressure is first rising to a value and then, having been taken past that value, subsequently falls to the same value

NOTE See Figure 2. SIST EN 15611:2009

Key 1 initial sensitivity 2 hysteresis 3 sensitivity at reversal NOTE The figure is simplified for illustrative purposes, e.g. the real pressure development is not shown. Figure 2 — Hysteresis and sensitivity 3.1.11 initial braking position first braking step corresponding to a reduction of the brake pipe pressure of 0,4 bar to 0,5 bar, which results in an input pressure to the relay valve of (0,7 ± 0,1) bar 3.1.12 normal litre Nl unit of mass for gases equal to the mass of 1 l at a pressure of 1,013 2 bar (1 atmosphere) and at a standard temperature, often 0 °C or 20 °C NOTE Airflow is often stated in normal litres per minute (Nl/min). 3.2 Symbols p pressure pi input pressure po output pressure t time SIST EN 15611:2009

Control signal - continuous load sensing pressure Lsp

Control signal - empty/load signal pressure AR Auxiliary reservoir pressure, supply pressure 4 Design and manufacture 4.1 General 4.1.1 A relay valve shall enable a distributor valve to be used without any vehicle specific modification to the distributor, related to the brake cylinder volume. This includes the independence of the brake application and release times, the inshot feature and the output pressure development for any output (brake cylinder and piping) volume. 4.1.2 The use of a relay valve shall not alter any of the characteristics of the distributor and/or a brake control unit that are not specified in this standard. 4.1.3 The use of a relay valve shall enable the vehicle to maintain a nominally constant brake application or release time. 4.1.4 The use of a relay valve shall enable the brake cylinder pressure to be maintained between prescribed limits (e.g. interoperable or national). These limits may be defined by different brake modes or speed-dependent requirements or where there is a requirement to maintain a nominal constant brake mass percentage irrespective of load. 4.1.5 Table 1 below provides a description of relay valve types described in this standard with the relevant clause references. SIST EN 15611:2009

3.1.6.1 Single stage relay valve 4.2.1 4.2.2.1 4.2.3 4.2.7 4.2.8 4.2.9 4.2.10 4.2.11 4.3 4.4 4.5 4.6 4.7 4.8 4.9 4.10 5 6.2.4.2 6.2.4.3 6.2.4.11 6.2.4.12 6.2.4.14 6.2.4.15 6.2.4.16 6.2.4.17 B – Basis of either B1 or B2 Types below Two or more fixed relay valve ratios Empty/loaded or

low/high 3.1.6.2 Multi stage relay valve 4.2.1 4.2.2.1 4.2.2.2 4.2.3 4.2.7

4.2.8 4.2.9

4.2.10 4.2.11 4.3 4.4 4.5 4.6 4.7 4.8 4.9 4.10 5 6.2.4.2 6.2.4.3 6.2.4.4 6.2.4.11 6.2.4.12 6.2.4.14 6.2.4.15 6.2.4.16 6.2.4.17 B1

Change of relay valve ratios required/allowed during brake application 3.1.6.2.1

As for Type B plus 4.2.4 As for type B plus 6.2.4.5 B2

Change of relay valve ratio not allowed during brake application 3.1.6.2.2

As for Type B plus 4.2.5 As for Type B plus 6.2.4.6C Continuously changing relay valve ratio

3.1.6.3 Variable load relay valve 4.2.1 4.2.2.1 4.2.3 4.2.5 4.2.7 4.2.8 4.2.9

4.2.10 4.2.11 4.3 4.4 4.5 4.6 4.7 4.8 4.9 4.10 5 6.2.4.2 6.2.4.3 6.2.4.6 6.2.4.7 6.2.4.8 6.2.4.12 6.2.4.14 6.2.4.15 6.2.4.16 6.2.4.17 C1

Continuously changing relay valve ratio, with a multi stage feature added 3.1.6.4 Multi stage variable load relay valve As for Type C plus 4.2.2.3 As for Type C plus 6.2.4.10 D Two or more input pressures with „select high“ feature overlay function to type A – C 3.1.6.5 Two (multi) input relay valveAs for Type A, B or C plus 4.2.2.4 As for Type A, B or C plus 6.2.4.13 E Kinked characteristic additional overlay function to type C 3.1.6.6 Variable load relay valve with kinked characteristic As for Type C plus 4.2.6 As for Type C plus 6.2.4.9 SIST EN 15611:2009

Key 1 empty condition 2 loaded condition 3 initial input pressure (0,7 ± 0,1) bar 4 initial output pressure loaded 5 initial output pressure unloaded Figure 3 — Example of the output pressure po of a relay valve (brake cylinder pressure) in relation to the input pressure pi for different conditions of vehicle load SIST EN 15611:2009

The design of the relay valve shall allow interaction with at least one of the following load signal types: a) manual empty-loaded signal, where this signal is provided by a lever, either mounted directly on the relay valve, or remotely operated on the vehicle to manually change from the low to the high output pressure, or vice versa; b) pneumatic empty/load signal, where the relay valve shall be designed to operate on receipt of the relevant signal pressure dependant on the brake system design, as follows: SIST EN 15611:2009

This requirement shall be tested in accordance with 6.2.4.6. 4.2.6 Kinked characteristic of a variable load relay valve (type E) A variable load relay valve with kinked characteristic may be specified for use on SS-Wagons with tread brakes. A relay valve with a kinked characteristic shall be designed to operate in association with distributor valves compliant with EN 15355, for use on tread braked wagons of greater than 14,5 t axle loads. The required characteristic shall reduce the output pressure (BCP) at lower brake demands whilst raising the output pressure (BCP), at moderate to high brake demands, to the equivalent value required to achieve the maximum braking rate at full load. The relay valve characteristic shall be designed such that a change of characteristic is achieved at input pressures A and B, see Figure 11, established for equivalent brake pipe reductions of 0,8 bar and 1,2 bar respectively as sensed by the distributor. The values of input pressures A and B shall be in the range of 1,8 bar to 2,0 bar and 2,9 bar to 3,15 bar respectively. The increase in output pressure (BCP) achieved between the input pressure values A and B shall increase in relation to the increase in input pressure. SIST EN 15611:2009

The following accuracy shall be achieved when the pair is fitted to a vehicle if necessary by adjustment of the relay valve output. The design of the relay valve shall allow for this adjustment to be made. In combination with a distributor valve of a defined type the relay valve shall ensure the following characteristics. a) For brake application: 1) For all distributor valve/relay valve combinations, except matched pairs of interoperable distributor valves and relay valves: i) For a test conducted using an actual distributor in combination with a relay valve for an input pressure to the distributor of 0 bar (emergency brake application) and with the distributor output pressure of (3,8 ± 0,1) bar, which forms the input to the relay valve, the accuracy of the relay valve output pressure shall be ± 0,2 bar. This applies to the empty and loaded conditions. ii) The output pressure rise time (brake application time measured using an emergency brake application from the start of the rise of the output pressure to 95 % of its maximum value) of the relay valve shall be 3 s to 6 s with an input pressure rise time to the relay valve of 3 s to 5 s. 2) For matched pairs of interoperable distributor valves and relay valves, if specifically required by the customer: i) For a test conducted using an actual distributor in combination with a relay valve for an input pressure to the distributor of 0 bar (emergency brake application) and with the distributor output pressure of (3,8 ± 0,1) bar, which forms the input to the relay valve, the accuracy of the relay valve output pressure shall be ± 0,1 bar, when achieved by adjustment of the matched pair. This applies to the empty and loaded conditions. ii) The output pressure rise time (brake application time measured using an emergency brake application from the start of the rise of the output pressure to 95 % of its maximum value) of the relay valve shall be 3 s to 6 s with an input pressure rise time to the relay valve of 3 s to 5 s. iii) For relay valves of type C, C1, D and E when used in a matched pair, this combination shall have a performance at intermediate load conditions Lcp3 and Lcp5 (see Table 6), providing an output pressure accuracy of ± 0,15 bar. At load condition Lcp4 the output pressure accuracy shall be ± 0,1 bar. This shall be tested with the load sensing pressure increasing from Lcp3. b) For brake release, all distributor valve/relay valve combinations: 1) The output pressure shall continuously follow the drop of the input pressure from its maximum to 0,1 bar. The time delay for the start of the drop of the output pressure shall be ≤ 10 % of the total allowed release time for the distributor valve; SIST EN 15611:2009

NOTE 2 The environment range limits specified are those that have a low probability of being exceeded. All specified values are maximum or limit values. These values may be reached, but do not occur permanently. Depending on the situation there may be different frequencies of occurrence related to a certain period of time.

NOTE 3 The environment requirements of this document cover the environment requirements of the HS RST TSI which only refers to EN 50125-1. The relay valve shall be tested in accordance with requirements given in Clause 6 of this standard including where required environmental/climatic testing. 4.4.2 Temperature The relay valves covered by this standard shall be able to operate:

at – 25 °C ≤ environmental temperature ≤

70 °C without any deviation from the technical requirements specified in Clause 4 in this standard; at – 40 °C ≤ environmental temperature < – 25 °C with allowed deviation from the technical requirements specified in this standard but without affecting the function of the relay valve. SIST EN 15611:2009

4.4.3.1 General The following environmental conditions shall be considered in the design of the relay valve. It shall be demonstrated that these environmental conditions have been taken into account in the design of the relay valve. It is sufficient for the supplier to make a declaration of conformity stating how the environmental conditions in the following clauses have been taken into account. If not specifically required to be tested as part of the type testing requirements in Clause 6 of this standard, suitable tests and/or design assessments considering the effect of the following environmental conditions on the relay valve, shall be used in the development/design proving of the relay valve, prior to type testing. 4.4.3.2 Altitude The relay valve shall be able to operate without restrictions up to an altitude of 2 000 m. 4.4.3.3 Humidity The following external humidity levels shall be considered: yearly average: ≤ 75 % relative humidity; on 30 days in the year continuously: between 75 % and 95 % relative humidity; on the other days occasionally: between 95 % and 100 % relative humidity; maximum absolute humidity: 30 g/m3 occurring in tunnels. An operationally caused infrequent and slight moisture condensation shall not lead to any malfunction or failure. The psychometric charts contained in EN 50125-1 shall be used to establish the range of variation of the relative humidity for the different temperature classes that it is considered will not be exceeded for more than 30 days per year.

At cooled surfaces, 100 % relative humidity can occur causing condensation on parts of equipment; this shall not lead to any malfunction or failure. Sudden changes of the air temperature local to the vehicle can cause condensation of water on parts of equipment with rate of 3 K/s and maximum variation of 40 K; these conditions particularly occurring when entering or leaving a tunnel shall not lead to any malfunction or failure of the equipment. SIST EN 15611:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...