EN 1390:2020

(Main)Wood preservatives - Determination of the eradicant action against Hylotrupes bajulus (Linnaeus) larvae - Laboratory method

Wood preservatives - Determination of the eradicant action against Hylotrupes bajulus (Linnaeus) larvae - Laboratory method

This document specifies a method for the determination of the eradicant action of a surface application of a fast and a slow acting wood preservative product or a deferred acting wood preservative product on solid wood infested with larvae of Hylotrupes bajulus (Linnaeus).

This method is applicable to:

- organic formulations, as supplied or as prepared in the laboratory by dilution of concentrates; or

- organic water-dispersible formulations, as supplied or as prepared in the laboratory by dilution of concentrates; or

- water-soluble products, for example, salts.

NOTE An ageing procedure cannot be combined with this method.

Holzschutzmittel - Bestimmung der bekämpfenden Wirkung gegenüber Larven von Hylotrupes bajulus (Linnaeus) - Laboratoriumsverfahren

Dieses Dokument legt ein Verfahren zur Bestimmung der bekämpfenden Wirkung eines schnell und eines langsam wirkenden Holzschutzmittels oder eines Holzschutzmittels mit verzögerter Wirkung bei der Behandlung der Oberfläche von Vollholz fest, das von Larven des Hylotrupes bajulus (Linnaeus) befallen ist.

Das Verfahren ist anwendbar für:

- organische Zubereitungen im Lieferzustand oder wie sie im Laboratorium durch Verdünnung von Konzentraten hergestellt werden; oder

- organische in Wasser dispergierbare Zubereitungen im Lieferzustand oder wie sie im Laboratorium durch Verdünnung von Konzentraten hergestellt werden; oder

- wasserlösliche Produkte, z. B. Salze.

ANMERKUNG Ein Alterungsverfahren kann mit diesem Verfahren nicht kombiniert werden.

Produits de préservation du bois - Détermination de l'action curative contre les larves d'Hylotrupes bajulus (Linnaeus) - Méthode de laboratoire

Le présent document prescrit une méthode de détermination de l'efficacité curative d'un produit de préservation du bois à action rapide ou à action lente, ou d'un produit de préservation du bois à action différée, appliqué par un traitement de surface, sur des pièces de bois massif infestées par des larves d'Hylotrupes bajulus (Linnaeus).

La présente méthode est applicable :

- soit aux formules organiques telles qu'elles sont fournies ou préparées au laboratoire par dilution de concentrés ;

- soit aux formules organiques hydrodispersables, telles qu'elles sont fournies ou préparées au laboratoire par dilution de concentrés ;

- soit aux produits hydrosolubles tels que les sels.

NOTE Une épreuve de vieillissement ne peut pas être combinée avec cette méthode.

Zaščitna sredstva za les - Ugotavljanje učinkovitosti zatiranja ličink hišnega kozlička Hylotrupes bajulus (Linnaeus) - Laboratorijska metoda

General Information

- Status

- Published

- Publication Date

- 07-Apr-2020

- Withdrawal Date

- 30-Oct-2020

- Technical Committee

- CEN/TC 38 - Durability of wood and derived materials

- Drafting Committee

- CEN/TC 38/WG 24 - Insect testing - (beetles - termites)

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 02-Dec-2025

- Completion Date

- 02-Dec-2025

Relations

- Effective Date

- 15-Apr-2020

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1390:2020 - Wood preservatives: Determination of the eradicant action against Hylotrupes bajulus (Linnaeus) larvae - laboratory method - is a CEN standard that defines a laboratory test to assess the curative (eradicant) effectiveness of surface-applied wood preservatives against larvae of the house longhorn beetle (Hylotrupes bajulus). The method simulates treatment of slightly attacked solid wood (e.g., beams) where insect tunnels are not exposed and provides a reproducible basis for comparing products and concentrations. It supersedes EN 1390:2006.

Key topics and technical requirements

- Scope and applicability

- Applies to organic formulations, organic water-dispersible formulations and water‑soluble products (e.g., salts).

- An ageing procedure cannot be combined with this test.

- Test principle

- Larvae are introduced into defined wood test specimens, allowed to establish, then a surface application of preservative is applied (brushing or pipetting). Larval mortality is assessed after a time appropriate to the preservative’s speed of action and compared with untreated controls.

- Biological material

- Use healthy H. bajulus larvae from cultures or from infested wood (with a rearing period).

- Accepted larval mass groups: 51–100 mg and 101–150 mg. Larvae >150 mg are unsuitable.

- Definition included for moribund larva (inactive but considered alive after test period).

- Test specimens and durations

- Test specimen wood species and quality are specified; test durations differ by product type: fast/slow acting (12 or 24 weeks) and deferred acting (52 weeks).

- Apparatus & conditions

- Culturing chamber at (28 ± 2) °C and (70 ± 5)% RH; testing chamber at controlled conditions (e.g., (21 ± 2) °C).

- Ventilated fume cupboard for treatments; safety precautions for solvents and toxic materials are emphasized.

- Sealing and reagents

- Paraffin wax recommended for aqueous systems; gelatine for organic-solvent systems.

- Water per EN ISO 3696; choice of solvent/diluent must not leave toxic residues.

- Examination

- Visual examination and optional radiography; record larval locations to assess penetration characteristics.

- Reporting

- Results expressed as mortality compared to controls; full test report elements are specified.

Applications and typical users

- Practical uses:

- Product development and efficacy screening of wood preservatives.

- Comparative laboratory evaluation for formulation optimization and concentration selection.

- Supporting regulatory submissions, certification and performance claims for timber protection.

- Typical users:

- Industrial laboratories testing wood-protecting chemicals.

- Wood-preservative manufacturers and formulators.

- Independent testing and certification bodies, research institutes, and quality control teams in timber and construction companies.

Related standards and references

- EN ISO 3696 - Water for analytical laboratory use.

- ISO 835:2007 - Laboratory glassware - Graduated pipettes.

- EN 1390:2020 replaces EN 1390:2006; it was prepared by CEN/TC 38 (Durability of wood and wood-based products).

Keywords: EN 1390:2020, wood preservatives, Hylotrupes bajulus, eradicant action, laboratory method, wood protection testing, timber preservation, larvae testing.

Get Certified

Connect with accredited certification bodies for this standard

ECOCERT

Organic and sustainability certification.

Eurofins Food Testing Global

Global leader in food, environment, and pharmaceutical product testing.

Intertek Bangladesh

Intertek certification and testing services in Bangladesh.

Sponsored listings

Frequently Asked Questions

EN 1390:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Wood preservatives - Determination of the eradicant action against Hylotrupes bajulus (Linnaeus) larvae - Laboratory method". This standard covers: This document specifies a method for the determination of the eradicant action of a surface application of a fast and a slow acting wood preservative product or a deferred acting wood preservative product on solid wood infested with larvae of Hylotrupes bajulus (Linnaeus). This method is applicable to: - organic formulations, as supplied or as prepared in the laboratory by dilution of concentrates; or - organic water-dispersible formulations, as supplied or as prepared in the laboratory by dilution of concentrates; or - water-soluble products, for example, salts. NOTE An ageing procedure cannot be combined with this method.

This document specifies a method for the determination of the eradicant action of a surface application of a fast and a slow acting wood preservative product or a deferred acting wood preservative product on solid wood infested with larvae of Hylotrupes bajulus (Linnaeus). This method is applicable to: - organic formulations, as supplied or as prepared in the laboratory by dilution of concentrates; or - organic water-dispersible formulations, as supplied or as prepared in the laboratory by dilution of concentrates; or - water-soluble products, for example, salts. NOTE An ageing procedure cannot be combined with this method.

EN 1390:2020 is classified under the following ICS (International Classification for Standards) categories: 71.100.50 - Wood-protecting chemicals. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1390:2020 has the following relationships with other standards: It is inter standard links to EN 1390:2006, CEN/TR 16823:2015, EN ISO 3696:1995, EN 14128:2020, CEN/TR 17809:2022, EN 14128:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1390:2020 is associated with the following European legislation: EU Directives/Regulations: 305/2011. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1390:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2020

Nadomešča:

SIST EN 1390:2006

Zaščitna sredstva za les - Ugotavljanje učinkovitosti zatiranja ličink hišnega

kozlička Hylotrupes bajulus (Linnaeus) - Laboratorijska metoda

Wood preservatives - Determination of the eradicant action against Hylotrupes bajulus

(Linnaeus) larvae - Laboratory method

Holzschutzmittel - Bestimmung der bekämpfenden Wirkung gegenüber Larven von

Hylotrupes bajulus (Linnaeus) - Laboratoriumsverfahren

Produits de préservation du bois - Détermination de l'action curative contre les larves

d'Hylotrupes bajulus (Linnaeus) - Méthode de laboratoire

Ta slovenski standard je istoveten z: EN 1390:2020

ICS:

71.100.50 Kemikalije za zaščito lesa Wood-protecting chemicals

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1390

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2020

EUROPÄISCHE NORM

ICS 71.100.50 Supersedes EN 1390:2006

English Version

Wood preservatives - Determination of the eradicant

action against Hylotrupes bajulus (Linnaeus) larvae -

Laboratory method

Produits de préservation du bois - Détermination de Holzschutzmittel - Bestimmung der bekämpfenden

l'action curative contre les larves d'Hylotrupes bajulus Wirkung gegenüber Larven von Hylotrupes bajulus

(Linnaeus) - Méthode de laboratoire (Linnaeus) - Laboratoriumsverfahren

This European Standard was approved by CEN on 24 February 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1390:2020 E

worldwide for CEN national Members.

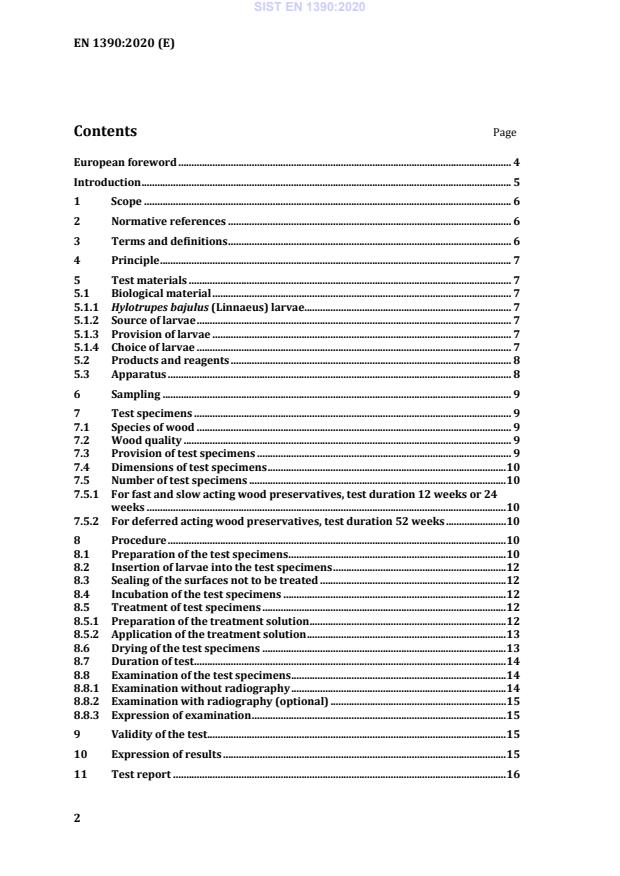

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Principle . 7

5 Test materials . 7

5.1 Biological material . 7

5.1.1 Hylotrupes bajulus (Linnaeus) larvae. 7

5.1.2 Source of larvae . 7

5.1.3 Provision of larvae . 7

5.1.4 Choice of larvae . 7

5.2 Products and reagents . 8

5.3 Apparatus . 8

6 Sampling . 9

7 Test specimens . 9

7.1 Species of wood . 9

7.2 Wood quality . 9

7.3 Provision of test specimens . 9

7.4 Dimensions of test specimens . 10

7.5 Number of test specimens . 10

7.5.1 For fast and slow acting wood preservatives, test duration 12 weeks or 24

weeks . 10

7.5.2 For deferred acting wood preservatives, test duration 52 weeks . 10

8 Procedure . 10

8.1 Preparation of the test specimens . 10

8.2 Insertion of larvae into the test specimens . 12

8.3 Sealing of the surfaces not to be treated . 12

8.4 Incubation of the test specimens . 12

8.5 Treatment of test specimens . 12

8.5.1 Preparation of the treatment solution . 12

8.5.2 Application of the treatment solution . 13

8.6 Drying of the test specimens . 13

8.7 Duration of test . 14

8.8 Examination of the test specimens . 14

8.8.1 Examination without radiography . 14

8.8.2 Examination with radiography (optional) . 15

8.8.3 Expression of examination . 15

9 Validity of the test . 15

10 Expression of results . 15

11 Test report . 16

Annex A (informative) Example of a test report . 17

Annex B (informative) Technique for culturing Hylotrupes bajulus (Linnaeus) . 19

B.1 General . 19

B.2 Obtaining parent beetles . 19

B.3 Mating . 19

B.4 Egg-laying . 19

B.5 Hatching of eggs . 20

B.6 Larval development . 20

B.7 Enemies and parasites . 21

Annex C (informative) Environmental, health and safety precautions within

chemical/biological laboratory . 22

Bibliography . 23

European foreword

This document (EN 1390:2020) has been prepared by Technical Committee CEN/TC 38

“Durability of wood and wood-based products”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of

an identical text or by endorsement, at the latest by October 2020, and conflicting national

standards shall be withdrawn at the latest by October 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject

of patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1390:2006.

Significant technical differences between this document and EN 1390:2006 are as follows:

a) introduction of a definition for moribund larvae;

b) because of the changes in a) verification of the conditions of recovered larvae becomes

needless and was deleted;

c) alternative coatings for sealing surfaces not to be treated may be used if they have no harmful

effect to the test insects and if their performance as sealants has been documented;

d) the following note was added to 8.8 “Examination of the test specimens”: It is useful to record

the location (distance from the nearest treated surface) of all larvae recovered because it

provides valuable information on penetration characteristic of the preservative.

NOTE Test results obtained according to earlier versions of this document and when the tests had

started before this version of EN 1390 was published are considered as valid.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary,

Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland,

Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden,

Switzerland, Turkey and the United Kingdom.

Introduction

This document describes a laboratory method of testing which gives a basis for the assessment of

the eradicant action of fast and slow acting wood preservatives and of deferred acting wood

preservatives against Hylotrupes bajulus. It allows determination of the lethal effect of a surface

application of a preservative product on a population of larvae previously introduced into the test

specimens.

The method simulates conditions in practice where a beam is treated, which is only slightly

attacked and where cutting away has not exposed insect tunnels. This represents a severe test of

the product.

In some particular instances, for example where the preservative is to be used on timbers of large

dimensions, laminated beams, blockboard, plywood and other panel products, other test methods

can be used to obtain complementary information on the effectiveness of the eradicant action of

a product. Such methods lie outside the scope of this document.

This laboratory method provides one criterion by which the value of a product can be assessed.

In making this assessment the methods by which the preservative may be applied should be taken

into account. It is further recommended that results from this test should be supplemented by

those from other appropriate tests, and above all by comparison with practical experience.

When products that are very active at low concentrations are used it is very important to take

suitable precautions to isolate and separate, as far as possible, operations involving chemical

products, other products, treated wood, laboratory apparatus and clothing. Suitable precautions

should include the use of separate rooms, areas within rooms, extraction facilities, conditioning

chambers and special training for personnel.

1 Scope

This document specifies a method for the determination of the eradicant action of a surface

application of a fast and a slow acting wood preservative product or a deferred acting wood

preservative product on solid wood infested with larvae of Hylotrupes bajulus (Linnaeus).

This method is applicable to:

— organic formulations, as supplied or as prepared in the laboratory by dilution of concentrates;

or

— organic water-dispersible formulations, as supplied or as prepared in the laboratory by

dilution of concentrates; or

— water-soluble products, for example, salts.

NOTE An ageing procedure cannot be combined with this method.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

EN ISO 3696, Water for analytical laboratory use — Specification and test methods (ISO 3696)

ISO 835:2007, Laboratory glassware — Graduated pipettes

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/ui

3.1

moribund larva

larva that is in the state of inactivity or obsolescence due to exposure to the test product but which

are considered alive after a specific test period

3.2

representative sample

sample with physical and/or chemical characteristics identical to the volumetric average

characteristics of the total volume being sampled

[SOURCE: EN 1001-2:2005, 4.71]

3.3

supplier

sponsor of the test (person or company providing the sample of wood preservative to be tested)

[SOURCE: Adapted from EN 1001-2:2005, 4.83]

4 Principle

Insertion of larvae of Hylotrupes bajulus into test specimens. After a period of time to allow the

larvae to establish themselves in the test specimens, treatment of these test specimens by

brushing or pipetting of the test preservative product.

After the time defined by the speed of action of the wood preservative, assessment of the mortality

of the larvae compared with that of larvae in untreated control test specimens.

5 Test materials

5.1 Biological material

5.1.1 Hylotrupes bajulus (Linnaeus) larvae

5.1.2 Source of larvae

The larvae shall preferably be obtained from cultures reared according to the method described

in Annex B.

Larvae can also be taken from naturally infested wood, in which case they should be transferred

into sapwood of pine and stored for at least four weeks under the rearing conditions specified in

Annex B.

5.1.3 Provision of larvae

Carefully split or crumble infested blocks to extract larvae.

Keep the larvae separate from one another in glass receptacles for two or three days in the

culturing chamber (5.3.1) to check they are healthy.

5.1.4 Choice of larvae

Use only healthy larvae in the test.

NOTE A healthy larva can be recognized by ivory-white colour, its firm consistency and rounded

appearance, and by the absence of wounds or bites, which show up as dark marks. Healthy larvae react to

the touch by vigorous movement and attempts to bite.

Reject any larvae, which are shrunken or aged which have recently moulted, or which are in a pre-

pupal stage.

Weigh each larva and place it in a glass receptacle marking the receptacle with the weight of the

larva. Make up two groups with the weight ranges:

— 51 mg to 100 mg, and

— 101 mg to 150 mg.

Larvae with a mass larger than 150 mg in mass are unsuitable as they can pupate during the

course of the test.

5.2 Products and reagents

5.2.1 Paraffin wax, for sealing the relevant surfaces of specimens to be treated with solutions

in which water is the continuous phase.

NOTE Paraffin wax with a setting point of 52 °C to 54 °C has been found suitable.

5.2.2 Gelatine, for sealing the relevant surfaces of specimens to be treated with solutions in

which an organic solvent is the continuous phase.

5.2.3 Water, complying with grade 3 of EN ISO 3696.

5.2.4 Solvent or diluent, a volatile liquid that will dissolve or dilute the preservative but does

not leave a residue in the wood at the end of the post-treatment conditioning period that has a

toxic effect on the insects.

CAUTION — Do not use benzene or other solvents which pose a health risk.

5.3 Apparatus

5.3.1 Culturing chamber, with air circulation, controlled at (28 ± 2) °C and at a relative

humidity of (70 ± 5) %.

5.3.2 Ventilated fume cupboard, in which the specimens are treated with an input air

temperature of (20 ± 5) °C.

The maximum air speed, measured at the input opening with the sash in the approximate

operation position should be approx. 0,5 m/s.

CAUTION — It is essential to follow safety procedures for handling flammable and toxic materials.

Avoid excessive exposure of operators to solvents or their vapours.

5.3.3 Testing chamber, ventilated and controlled at (21 ± 2) °C and at a relative humidity of

(75 ± 5) %.

5.3.4 Drill and twist drills, with 3 mm, 4 mm and 5 mm diameters.

5.3.5 Pipettes as specified in ISO 835:2007, Class B - graduated pipette with no waiting time,

with a capacity 5 ml and an accuracy of ±0,05 ml.

5.3.6 Brush of appropriate size, to be used when the test substance is applied by brushing

(8.5.2).

5.3.7 Safety equipment and protective clothing, appropriate for the test product and the test,

to ensure the safety of the operator (see also Annex C).

5.3.8 Ordinary laboratory equipment, including a balance capable of weighing to an accuracy

of ±1 mg.

5.3.9 Rectangular cover with sides, constructed either of glass, plastics, plywood and of a

height not less than 200 mm and with an open face of sufficient size to cover all the treated

specimens from a single test.

5.3.10 X-ray apparatus (optional) with tungsten target and beryllium window, with voltage

and current continuously variable in the ranges:

— voltage: 10 kV to 50 kV;

— current: 0 mA to 15 mA.

5.3.11 Protective gloves.

6 Sampling

The sample of preservative shall represent the product to be tested. Samples shall be stored and

handled in accordance with any written recommendations from the supplier.

For the sampling of preservatives from bulk supplies, the procedure given in EN 212 should be

used.

7 Test specimens

7.1 Species of wood

The reference species is Scots pine (Pinus sylvestris Linnaeus).

NOTE In southern European countries the species of pine most frequently infested by Hylotrupes

bajulus can be used as an alternative, provided that the suitability of the species for use in the tests specified

in this standard has been demonstrated in all aspects (development of larvae, resistance to impregnation,

etc.).

Additional tests may be carried out using other species but, if so, this should be stated in the test

report.

7.2 Wood quality

The wood shall be free from visible cracks, stain, decay, insect damage and other defects. The

wood shall not have been water-stored, floated, chemically treated or steamed.

The wood should preferably be felled in winter.

Wood that has been kiln dried at temperatures below 60 °C may be used.

The wood should not have been stored for more than five years.

The wood shall be exclusively sapwood containing little resin and having between two and a half

annual rings per 10 mm and eight annual rings per 10 mm. The proportion of latewood in the

annual rings shall not exceed 30 % of the whole.

It is recommended to use test specimens of a similar growth rate within a single test.

7.3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...