FprEN 1568-2

(Main)Fire extinguishing media - Foam concentrates - Part 2: Specification for high expansion foam concentrates for surface application to water-immiscible liquids

Fire extinguishing media - Foam concentrates - Part 2: Specification for high expansion foam concentrates for surface application to water-immiscible liquids

This document specifies requirements for chemical and physical properties, and minimum performance requirements of high expansion foams suitable for surface application to water-immiscible liquids. Requirements are also given for marking.

WARNING - Any type approval according to this document is invalidated by any change in composition of the approved product.

NOTE 1 Some concentrates conforming to this document can also conform to other parts of the EN 1568 series and therefore can also be suitable for application as low and/or medium expansion foams.

NOTE 2 For national deviations, see Annex Q.

Feuerlöschmittel - Schaummittel - Teil 2: Anforderungen an Schaummittel zur Erzeugung von Leichtschaum zum Aufgeben auf mit Wasser nicht mischbaren Flüssigkeiten

Dieses Dokument legt Anforderungen an chemische und physikalische Eigenschaften und Mindestanforderun

gen an die Leistungsfähigkeit von Leichtschäumen fest, die für die Aufgabe auf mit Wasser nicht mischbare Flüssigkeiten geeignet sind. Anforderungen an die Kennzeichnung sind ebenfalls festgelegt.

WARNUNG— Jeder Typ-Prüfbescheid nach dieser Norm wird bei Änderung der Zusammensetzung des geprüften Produktes ungültig.

ANMERKUNG Einige diesem Dokument entsprechende Schaummittel können auch mit den anderen Teilen überein

stimmen und deshalb auch für die Anwendung als Schwer- und/oder Mittelschäume geeignet sein.

Agents extincteurs - Émulseurs - Partie 2 : Spécifications pour les émulseurs à haut foisonnement destinés à une application à la surface de liquides n'ayant pas d'affinité pour l'eau

Le présent document spécifie les exigences en matière de propriétés chimiques, physiques et de performances minimales des émulseurs à haut foisonnement adaptées à une application à la surface de liquides n’ayant pas d’affinité pour l’eau. Des exigences concernant les marquages sont également fournies.

AVERTISSEMENT — Toute modification de la composition du produit approuvé annule toute homologation selon la présente norme.

NOTE Il se peut que certains émulseurs conformes au présent document soient également conformes à d’autres parties de cette série de normes et qu’ils conviennent donc à une application comme émulseurs à bas et/ou moyen foisonnement.

Gasila - Penila - 2. del: Specifikacija za penila za lahko peno za površinsko uporabo pri tekočinah, netopnih v vodi

General Information

- Status

- Not Published

- Publication Date

- 01-Apr-2026

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/WG 3 - Fire extinguishing media - Foam

- Current Stage

- 5020 - Submission to Vote - Formal Approval

- Start Date

- 11-Dec-2025

- Due Date

- 18-Sep-2026

- Completion Date

- 11-Dec-2025

Relations

- Effective Date

- 19-Jan-2023

Overview

FprEN 1568-2 (CEN) is the draft European standard that specifies requirements for high expansion foam concentrates used for surface application to water-immiscible liquids (Class B fires). Part of the EN 1568 series on fire extinguishing media - foam concentrates, this document updates and will supersede EN 1568-2:2018. It covers chemical and physical properties, minimum performance criteria, marking and quality control for concentrates intended to produce high expansion foam (expansion ratio ≥ 200).

Key points

- Applies to high expansion foam concentrates for surface application to liquids not miscible with water.

- Warning: any change in product composition invalidates type approval.

- Some concentrates may also meet other EN 1568 parts (low/medium expansion).

Key topics and requirements

The standard defines tests, properties and documentation required for conformity, including:

- Expansion and drainage time (25 % / 50 % drainage time, expansion ratio) - essential foam performance metrics.

- Sediment (solid deposits) before and after ageing - limits and test procedures.

- Freezing point - minimum performance after temperature exposure.

- Viscosity - Newtonian and pseudo‑plastic behaviour and test temperatures.

- pH and surface tension of foam concentrate/solution.

- Stability/separation tests for concentrate homogeneity.

- Test fire performance - controlled fire tests to verify extinguishing capability under specified conditions (with temperature and wind speed measurement requirements).

- Occupational health and ecotoxicology - test protocols and labelling in line with CLP / REACH and referenced OECD methods.

- Annual foam quality check (optional) and technical information sheet requirements.

- Container marking and designation to guarantee consistency of formulation and performance.

Practical applications and users

FprEN 1568-2 is intended for:

- Foam concentrate manufacturers developing high expansion formulations and seeking European type approval.

- Fire‑testing laboratories (EN ISO/IEC 17025) performing performance and ageing tests.

- Fire protection engineers and specifiers selecting foam systems for storage terminals, shipboard applications, hangars and industrial sites handling water‑immiscible fuels.

- Regulatory authorities, procurement teams and safety officers assessing compliance, labelling and environmental/health data.

This standard helps ensure reliable firefighting performance, correct product marking, and safer, more environmentally informed use of high expansion foam concentrates.

Related standards

- EN 1568-1 (medium expansion)

- EN 1568-3 (low expansion for water‑immiscible liquids)

- EN 1568-4 (low expansion for water‑miscible liquids)

Also references ISO, EN ISO and OECD test methods for viscosity, surface tension, biodegradability and ecotoxicology.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

FprEN 1568-2 is a draft published by the European Committee for Standardization (CEN). Its full title is "Fire extinguishing media - Foam concentrates - Part 2: Specification for high expansion foam concentrates for surface application to water-immiscible liquids". This standard covers: This document specifies requirements for chemical and physical properties, and minimum performance requirements of high expansion foams suitable for surface application to water-immiscible liquids. Requirements are also given for marking. WARNING - Any type approval according to this document is invalidated by any change in composition of the approved product. NOTE 1 Some concentrates conforming to this document can also conform to other parts of the EN 1568 series and therefore can also be suitable for application as low and/or medium expansion foams. NOTE 2 For national deviations, see Annex Q.

This document specifies requirements for chemical and physical properties, and minimum performance requirements of high expansion foams suitable for surface application to water-immiscible liquids. Requirements are also given for marking. WARNING - Any type approval according to this document is invalidated by any change in composition of the approved product. NOTE 1 Some concentrates conforming to this document can also conform to other parts of the EN 1568 series and therefore can also be suitable for application as low and/or medium expansion foams. NOTE 2 For national deviations, see Annex Q.

FprEN 1568-2 is classified under the following ICS (International Classification for Standards) categories: 13.220.10 - Fire-fighting. The ICS classification helps identify the subject area and facilitates finding related standards.

FprEN 1568-2 has the following relationships with other standards: It is inter standard links to EN 1568-2:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

FprEN 1568-2 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN 1568-2:2025

01-junij-2025

Gasila - Penila - 2. del: Specifikacija za penila za lahko peno za površinsko

uporabo pri tekočinah, netopnih v vodi

Fire extinguishing media - Foam concentrates - Part 2: Specification for high expansion

foam concentrates for surface application to water-immiscible liquids

Feuerlöschmittel - Schaummittel - Teil 2: Anforderungen an Schaummittel zur Erzeugung

von Leichtschaum zum Aufgeben auf mit Wasser nicht mischbaren Flüssigkeiten

Agents extincteurs - Émulseurs - Partie 2 : Spécifications pour les émulseurs à haut

foisonnement destinés à une application à la surface de liquides n'ayant pas d'affinité

pour l'eau

Ta slovenski standard je istoveten z: prEN 1568-2

ICS:

13.220.10 Gašenje požara Fire-fighting

oSIST prEN 1568-2:2025 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

oSIST prEN 1568-2:2025

oSIST prEN 1568-2:2025

DRAFT

EUROPEAN STANDARD

prEN 1568-2

NORME EUROPÉENNE

EUROPÄISCHE NORM

April 2025

ICS 13.220.10 Will supersede EN 1568-2:2018

English Version

Fire extinguishing media - Foam concentrates - Part 2:

Specification for high expansion foam concentrates for

surface application to water-immiscible liquids

Agents extincteurs - Émulseurs - Partie 2 : Feuerlöschmittel - Schaummittel - Teil 2:

Spécifications pour les émulseurs à haut foisonnement Anforderungen an Schaummittel zur Erzeugung von

destinés à une application à la surface de liquides Leichtschaum zum Aufgeben auf mit Wasser nicht

n'ayant pas d'affinité pour l'eau mischbaren Flüssigkeiten

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 191.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 1568-2:2025 E

worldwide for CEN national Members.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

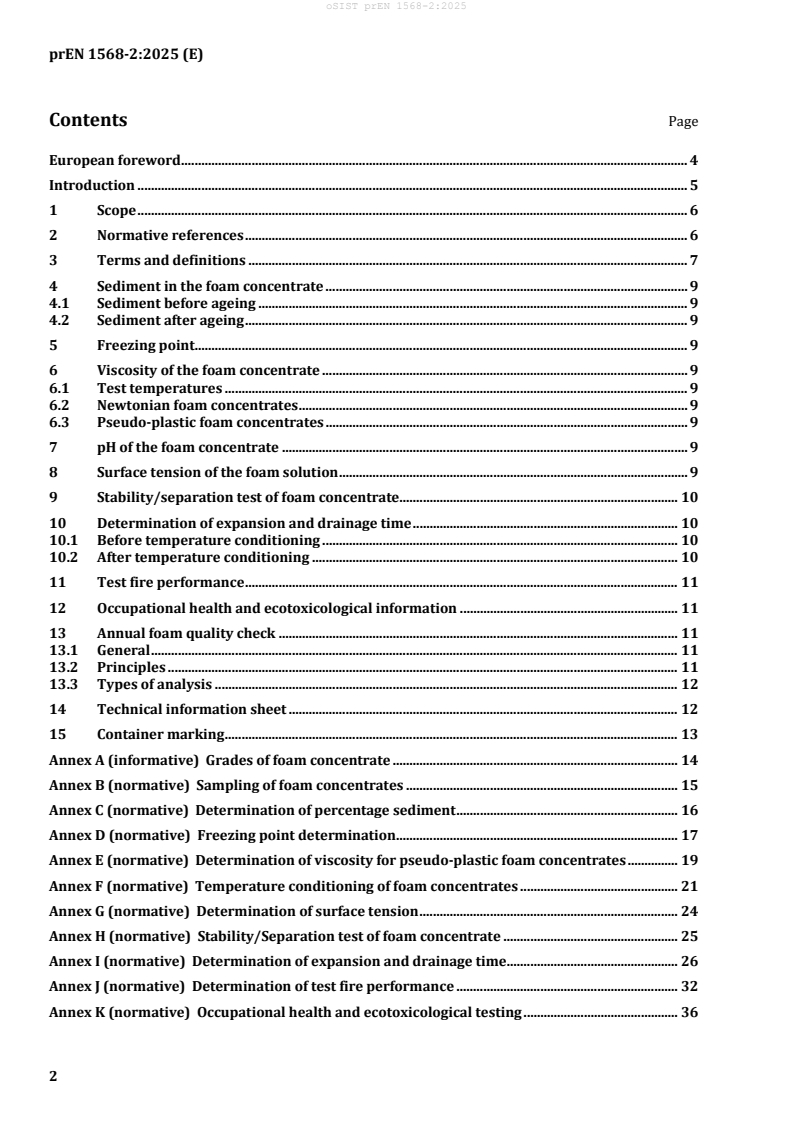

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Sediment in the foam concentrate . 9

4.1 Sediment before ageing . 9

4.2 Sediment after ageing . 9

5 Freezing point. 9

6 Viscosity of the foam concentrate . 9

6.1 Test temperatures . 9

6.2 Newtonian foam concentrates . 9

6.3 Pseudo-plastic foam concentrates . 9

7 pH of the foam concentrate . 9

8 Surface tension of the foam solution . 9

9 Stability/separation test of foam concentrate . 10

10 Determination of expansion and drainage time . 10

10.1 Before temperature conditioning . 10

10.2 After temperature conditioning . 10

11 Test fire performance . 11

12 Occupational health and ecotoxicological information . 11

13 Annual foam quality check . 11

13.1 General . 11

13.2 Principles . 11

13.3 Types of analysis . 12

14 Technical information sheet . 12

15 Container marking . 13

Annex A (informative) Grades of foam concentrate . 14

Annex B (normative) Sampling of foam concentrates . 15

Annex C (normative) Determination of percentage sediment . 16

Annex D (normative) Freezing point determination . 17

Annex E (normative) Determination of viscosity for pseudo-plastic foam concentrates . 19

Annex F (normative) Temperature conditioning of foam concentrates . 21

Annex G (normative) Determination of surface tension . 24

Annex H (normative) Stability/Separation test of foam concentrate . 25

Annex I (normative) Determination of expansion and drainage time . 26

Annex J (normative) Determination of test fire performance . 32

Annex K (normative) Occupational health and ecotoxicological testing . 36

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

Annex L (informative) Annual foam quality check . 37

Annex M (informative) Example for a technical information sheet . 41

Annex N (informative) A-Deviations . 44

Bibliography . 46

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

European foreword

This document (prEN 1568-2:2025) has been prepared by Technical Committee CEN/TC 191 “Fixed

firefighting systems”, the secretariat of which is held by BSI.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 1568-2:2018.

This document includes the following significant technical changes with respect to EN 1568-2:2018:

— Determination of solid deposits for synthetic foams and protein foams clarified;

— Optional annual foam quality check introduced;

— Temperature and wind speed measurements for performance fire test clarified;

— Some test procedures clarified.

This document is Part 2 of EN 1568 which has the general title Fire extinguishing media — Foam

concentrates. The other parts are:

— Part 1: Specification for medium expansion foam concentrates for surface application to water-

immiscible liquids;

— Part 3: Specification for low expansion foam concentrates for surface application to water-immiscible

liquids;

— Part 4: Specification for low expansion foam concentrates for surface application to water-miscible

liquids.

This document is one of a series of standards specifying requirements for fire extinguishing media in

common use. This series includes the following standards:

— EN ISO 5923, Equipment for fire protection and fire fighting — Fire extinguishing media — Carbon

dioxide;

— EN 27201-1, Fire protection — Fire extinguishing media - Halogenated hydrocarbons — Part 1:

Specifications for halon 1211 and halon 1301 (ISO 7201-1);

— EN 27201-2, Fire protection — Fire extinguishing media — Halogenated hydrocarbons — Part 2: Code

of practice for safe handling and transfer procedures (ISO 7201-2);

— EN 615, Fire protection — Fire extinguishing media — Specifications for powders (other than class D

powders).

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

Introduction

As fire-fighting foams are chemical agents or chemical preparations, Commission Directive 2000/60/CE

and Regulations (EC) No 1272/2008 (CLP) and No 1907/2006 (REACH) apply and should be taken into

account.

Classes of fire are defined in EN 2 as follows:

— Class A: fires involving solid materials, usually of an organic nature, in which combustion normally

takes place with the formation of glowing embers;

— Class B: fires involving liquids or liquefiable solids;

— Class C: fires involving gases;

— Class D: fires involving metals;

— Class F: fires involving cooking media (vegetable or animal oils and fats) in cooking appliances.

Fire-fighting foams are widely used to control and extinguish Class B fires and to inhibit re-ignition. These

foams can also be used for prevention of ignition of flammable liquids and, in certain conditions, to

extinguish Class A fires.

Foams can be used in combination with other extinguishing media, particularly gaseous media and

powders, which are the subject of other European Standards (see European foreword).

These specifications have been designed to ensure that fire extinguishing media have the minimum useful

fire fighting capability. The user should ensure that the foam concentrates are used accurately at the

concentration recommended by the manufacturer. Fire performances indicated by this standard cannot

replicate practical fire situations.

Foam concentrates of different types and manufacturers should not be mixed.

It should be noted that some combinations of extinguishing powder and foam can lead to unacceptable

loss of efficiency, caused by unfavourable interaction of the chosen media when applied simultaneously

or successively to the fire.

It is extremely important that the foam concentrate after dilution with water to the recommended

concentration should not in normal usage present a significant toxic hazard to life in relation to the

environment. The current version of Commission Directive 2000/60/CE,

Regulations (EC) No 1272/2008 (CLP) and No 1907/2006 (REACH) apply when considering the testing

of ecotoxicological properties and safety in the work environment.

A special quality characteristic is the type test conducted by an independent testing laboratory accredited

to EN ISO/IEC 17025.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

1 Scope

This document specifies requirements for chemical and physical properties, and minimum performance

requirements of high expansion foams suitable for surface application to water-immiscible liquids.

Requirements are also given for marking.

WARNING — Any type approval according to this standard is invalidated by any change in

composition of the approved product.

NOTE Some concentrates conforming to this document can also conform to other parts and therefore can also

be suitable for application as low and/or medium expansion foams.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1568 (all parts), Fire extinguishing media - Foam concentrates

prEN 1568-4:—, Fire extinguishing media - Foam concentrates - Part 4: Specification for low expansion

foam concentrates for surface application to water-miscible liquids

EN ISO 2811-1, Paints and varnishes - Determination of density - Part 1: Pycnometer method (ISO 2811-1)

EN ISO 3104, Petroleum products - Transparent and opaque liquids - Determination of kinematic viscosity

and calculation of dynamic viscosity (ISO 3104)

EN ISO 3219-2:2021, Rheology - Part 2: General principles of rotational and oscillatory rheometry (ISO

3219-2:2021)

EN ISO 3675, Crude petroleum and liquid petroleum products - Laboratory determination of density -

Hydrometer method (ISO 3675)

EN ISO 3696, Water for analytical laboratory use - Specification and test methods (ISO 3696)

EN ISO 11348-2, Water quality - Determination of the inhibitory effect of water samples on the light

emission of Vibrio fischeri (Luminescent bacteria test) - Part 2: Method using liquid-dried bacteria (ISO

11348-2)

EN ISO 23753-1, Soil quality - Determination of dehydrogenases activity in soils - Part 1: Method using

triphenyltetrazolium chloride (TTC) (ISO 23753-1)

ISO 304, Surface active agents — Determination of surface tension by drawing up liquid films

ISO 3310-1, Test sieves — Technical requirements and testing — Part 1: Test sieves of metal wire cloth

OECD 201, Test No. 201: Freshwater Alga and Cyanobacteria, Growth Inhibition Test

OECD 202, Test No. 202: Daphnia sp. Acute Immobilisation Test

Under preparation. Stage at the time of publication: prEN 1568-4:2025.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

OECD 203, Test No. 203: Fish, Acute Toxicity Test

OECD 301, Test No. 301: Ready Biodegradability

OECD 404, Test No. 404: Acute Dermal Irritation/Corrosion

OECD 405, Test No. 405: Acute Eye Irritation/Corrosion

OECD 420, Test No. 420: Acute Oral Toxicity - Fixed Dose Procedure

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/ ;

— ISO Online browsing platform: available at http://www.iso.org/obp .

3.1

25 %/50 % drainage time

time taken for 25 %/50 % of the volume of the original foam solution to drain out of the generated foam

3.2

expansion (E)

expansion value

expansion ratio

ratio of the volume of foam to the volume of the foam solution from which it was made

3.3

low expansion foam

foam which has an expansion ratio less than 20

3.4

medium expansion foam

foam which has an expansion ratio greater than or equal to 20 but less than 200

3.5

high expansion foam

foam which has an expansion ratio greater than or equal to 200

3.6

fire-fighting foam

aggregate of air filled bubbles formed from a foam solution used for fire-fighting

3.7

foam concentrate

liquid which is diluted with water to produce foam solution

Note 1 to entry: Annex A gives information on grades of foam concentrate.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

3.8

foam solution

homogeneous mixture of foam concentrate and water in the proportions as specified by the foam

concentrate manufacturer

3.9

premix

foam solution prepared in a batch process by introducing a measured amount of foam concentrate into a

given amount of water in storage

3.10

sediment

insoluble particles in the foam concentrate

3.11

Newtonian foam concentrate

foam concentrate which has a viscosity which is independent of the shear rate

3.12

pseudo-plastic foam concentrate

foam concentrate which has a viscosity which decreases with increasing shear rate

3.13

surface tension

tension within the interface between a liquid and air

3.14

freezing point

temperature at which the first ingredient of a mixture starts to solidify or freeze out

3.15

designation

identifying name

name that corresponds to a chemical formulation and a specific production process

Note 1 to entry: It guarantees consistency of the characteristics, performance and conditions of use of the foam

concentrate.

3.16

demineralized water

−1

water conforming to EN ISO 3696 (Grade 3), or having a surface tension greater than 70 mN⋅m and a

−1

conductivity of ≤ 5 μS⋅cm

Note 1 to entry: Surface tension tested in accordance with Clause G.2.

3.17

qualified personnel

designated individual, suitably trained, competent through knowledge and practical experience and with the

necessary instruction to enable the tests and examinations to be carried out

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

4 Sediment in the foam concentrate

4.1 Sediment before ageing

Any sediment in the foam concentrate sampled in accordance with Annex B, but not aged in accordance

with Clause C.1, shall be dispersible through a 180 μm sieve, and the percentage volume of sediment shall

be not more than 0,25 % when tested in accordance with Annex C.

4.2 Sediment after ageing

Any sediment in the foam concentrate sampled in accordance with Annex B, and aged in accordance with

Clause C.1, shall be dispersible through a 180 μm sieve and the percentage volume of sediment shall be

not more than 1,0 % when tested in accordance with Annex C.

5 Freezing point

The freezing point of the foam concentrate sampled in accordance with Annex B shall be determined in

accordance with Annex D.

6 Viscosity of the foam concentrate

6.1 Test temperatures

The viscosity of the foam concentrate shall be measured from 20 °C, to and including the lowest

temperature for use claimed by the manufacturer in steps of 10 °C. Use a fresh sample for each

temperature.

6.2 Newtonian foam concentrates

The viscosity of the foam concentrate at the lowest temperature for use claimed by the manufacturer

2 –1

shall be determined in accordance with EN ISO 3104. If the viscosity is > 200 mm s , the container

shall be marked in accordance with Clause 15 j).

6.3 Pseudo-plastic foam concentrates

The viscosity of the foam concentrate shall be determined in accordance with Annex E. If the viscosity at

−1

the lowest temperature for use is greater than or equal to 120 mPa·s at 375 s , the container shall be

marked in accordance with Clause 15 k).

7 pH of the foam concentrate

The pH of the foam concentrate sampled in accordance with Annex B shall be not less than 6,0 and not

more than 9,5 at (20 ± 1) °C.

8 Surface tension of the foam solution

The surface tension (determined in accordance with Clause G.2) of the foam solutions prepared using top

and bottom half-samples (see Clause F.4) of the foam concentrate, sampled in accordance with Annex B

and conditioned in accordance with Annex F, shall be not less than 0,95 times and not more than 1,05

times the surface tension of the foam solution prepared using the sampled foam concentrate.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

9 Stability/separation test of foam concentrate

The foam concentrate shall not separate, stratify or precipitate as indicated by two or more distinct layers

when tested in accordance with Annex H.

The amount of solid deposits of the aged sample determined according to Annex C at 20 °C in synthetic

foams shall not increase from the fresh sample.

The amount of solid deposits of the aged sample determined according to Annex C at 20 °C in protein

foams shall not increase by more than 4 times the amount obtained from the fresh sample, and shall not

exceed a volume fraction of 1 % in total.

10 Determination of expansion and drainage time

10.1 Before temperature conditioning

The foam produced from the foam solution, prepared from the foam concentrate sampled in accordance

with Annex B, at the supplier’s recommended concentration with simulated fresh water in accordance

with Clause I.4, shall be tested in accordance with Annex I and give an expansion according to 3.5. If

appropriate, a further sample of the same concentration made with the simulated sea water in accordance

with Clause I.4 shall also be tested.

NOTE Expansion is dependent on the foam concentrate and the equipment used to make the foam.

10.2 After temperature conditioning

The foams produced from the solutions prepared with simulated fresh water by using top and bottom

half-samples (see Clause F.4) of foam concentrate, sampled in accordance with Annex B, at the supplier’s

recommended concentration, when tested in accordance with Annex I, shall have the following:

a) expansions which do not differ from each other or from the value obtained according to 10.1 using

simulated fresh water (i.e. before temperature conditioning) by more than 20 % of the value

obtained according to 10.1 using simulated fresh water; and

b) 25 % drainage times which do not differ from each other or from the value obtained according to

10.1 using simulated fresh water (i.e. before temperature conditioning) by more than 20 % of the

value obtained according to 10.1 using simulated fresh water.

If appropriate, the tests shall be repeated using top and bottom half-samples (see Clause F.4) of foam

concentrate, sampled in accordance with Annex B, at the supplier’s recommended concentration, using

foam solutions prepared with the simulated sea water in accordance with Clause I.4. These foam

solutions shall have the following:

c) expansions which do not differ from each other or from the value obtained according to 10.1 using

the simulated sea water (i.e. before temperature conditioning) by more than 20 % of the value

obtained according to 10.1 using the simulated sea water in accordance with Clause I.4; and,

d) 25 % drainage times which do not differ from each other or from the value obtained according to

10.1 using the simulated sea water (i.e. before temperature conditioning) by more than 20 % of the

value obtained according to 10.1 using the simulated sea water in accordance with Clause I.4.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

11 Test fire performance

The foam produced from foam solution, prepared using the foam concentrate, sampled in accordance

with Annex B at the supplier's recommended concentration with simulated fresh water in accordance

with Clause I.4, and if appropriate at the same concentration with the simulated sea water in accordance

with Clause I.4, shall have an extinction time not more than 150 s when tested in accordance with

Clause J.2 and Clause J.3.

NOTE 1 The values obtained with simulated sea water can differ from those obtained with simulated fresh water.

NOTE 2 The lack of homogeneity of the premix can influence the firefighting performance of the foam generated

from it.

12 Occupational health and ecotoxicological information

The manufacturer shall provide information as specified in Annex K.

If the data for the ecotoxicological report was generated by a third party, this data may be added to the

test report or may be added as a reference. If the toxicological/ecotoxicological data were generated by

application of mathematical methodologies in accordance with Annex K the corresponding report shall

be added to the report confirming conformity with this document.

If the toxicological/ecotoxicological data were generated by an independent third party the data may be

added to the report confirming conformity to this document either as a report or as a reference to the

report-ID given by the third party.

13 Annual foam quality check

13.1 General

Firefighting foam concentrates are recommended to be checked annually for their quality, indicating their

functionality. The test program described in 13.2 is considered to be a collection of analytical methods

which in its entirety is suitable to detect degradation or a declining function of a foam concentrate.

The outcome of the annual foam quality check described in 13.2 is intended to be used to qualify or

disqualify a foam concentrate for its further usability. Therefore, the quality of testing and evaluation of

test data is a special quality characteristic of the body executing the foam quality check.

13.2 Principles

13.2.1 The sample of the foam concentrate(s) shall be collected in such a way, that the sample is

representative of the stored volume.

13.2.2 A full declaration of the foam product’s identity, hazards associated with it [see section 2 of the

most recent material safety data sheet (MSDS)], as well as information on PFAS content, proportioning

rate, age, storage condition and possible contaminations shall be given.

13.2.3 For foam concentrates which can be used as low, medium and high expansion foam the desired

testing expansion shall be specified as well as the water quality (simulated fresh or sea water) to be used.

13.2.4 Packing and labelling of foam concentrate samples is subject to European regulation on packaging

and labelling of chemical mixtures (Regulation (EC) No 1272/2008, CLP, e.g. Article 35).

13.2.5 The equipment for testing shall be calibrated and maintained in full function.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

13.2.6 The foam concentrate sample should be processed as it was received. If stratification,

sedimentation or other inhomogeneities are visible, that sample shall not be homogenised prior to

testing. Instead, the sample may be considered as a fail.

13.2.7 A comprehensive test report with all tested results should be provided. The report may include

evaluation of the obtained results and further recommendations. If this is the case, this shall be indicated

as an evaluation of the data based on the experience and knowledge of the body executing the foam

quality test.

13.2.8 The test data shall be compared with the technical data of the respective foam concentrate given

by the manufacturer.

13.3 Types of analysis

Table 2 indicates the type of analysis that should be run for a given type of foam concentrate. Annex N

gives test descriptions and requirements.

Table 2 — Types of analysis

AR non-AR medium high

expansion expansion

application application

Visual examination X X X X

Density at (20 ± 1) °C X X X X

pH-value at (20 ± 1) °C X X X X

Sediment at (20 ± 1) °C X X X X

Viscosity at (20 ± 1) °C X X X X

Refractive index at (20 ± 1) °C X X X X

25 %-drainage, low expansion X X — —

foam

25 %-drainage, medium — — X —

expansion foam

25 %-drainage, high expansion — — — X

foam

expansion, low expansion foam X X — —

expansion, medium expansion — — X —

foam

expansion, high expansion — — — X

foam

Resistance to isopropanol X — — —

14 Technical information sheet

The manufacturer should provide information for the foam concentrate. An example of the type of

information provided in a manufacturers' technical information sheet is given in Annex M.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

15 Container marking

Markings on shipping containers should be permanent and legible. The following information shall be

marked on the packaging or transport container:

a) the designation (identifying name) of the concentrate;

b) the words “high expansion fire-fighting foam concentrate” and the number and publication date of

this document (i.e. EN 1568-2:2025);

NOTE 1 For high expansion concentrates which also conform to other parts of EN 1568 additional markings

can be used as given in those parts.

c) recommended usage concentration (most commonly 1 %, 3 % or 6 %);

d) recommended maximum storage temperature, lowest temperature for use and freezing point;

e) if the manufacturer advises that the foam concentrate is adversely affected by low temperature

storage according to Annex F, the words 'Do not freeze';

f) the nominal quantity in the container;

g) the supplier's name and address;

h) the batch number and the date of manufacture;

i) the words “Not suitable for use with sea water” or “Suitable for use with sea water” as appropriate;

j) if the foam concentrate is Newtonian and the viscosity at the lowest temperature for use is more than

2 -1

200 mm s when measured in accordance with EN ISO 3104 the words “This concentrate can

require special proportioning equipment”;

k) if the foam concentrate is pseudo-plastic and the viscosity at the lowest temperature for use is greater

−1

than or equal to 120 mPa·s at 375 s the words “Pseudo-plastic foam concentrate. This concentrate

can require special proportioning equipment”;

l) the lowest extinguishing performance class and the lowest burn-back resistance level obtained

during testing to each part of EN 1568 (if tested to more than one part) with all fuels in simulated

fresh water and sea water.

NOTE 2 The marking of shipping containers shipped to laboratories for testing are exempt from this

requirement.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

Annex A

(informative)

Grades of foam concentrate

Foam concentrate are graded as follows:

a) protein foam concentrates (P): these are liquids derived from hydrolysed protein materials;

b) fluoroprotein foam concentrates (FP): these are protein concentrates with added fluorinated surface

active agents;

c) synthetic foam concentrates (S): these are based upon mixtures of hydrocarbon surface-active agents

and do not contain fluoro organic compounds;

d) alcohol resistant foam concentrates (AR): these can be suitable for use on hydrocarbon fuels, and

additionally are resistant to breakdown when applied to the surface of water-miscible liquid fuels;

some alcohol resistant foam concentrates can precipitate a polymeric membrane on the surface of

alcohol;

e) aqueous film-forming foam concentrates (AFFF): these are based on mixtures of hydrocarbon

surfactants and fluorinated surface active agents and have the ability to form an aqueous film on the

surface of some hydrocarbon fuels;

f) film-forming fluoroprotein foam concentrates (FFFP): these are fluoroprotein foam concentrates

which have the ability to form an aqueous film on the surface of some hydrocarbon fuels;

g) fluorine free foam concentrates (F3): these foam concentrates are dedicated to meet extinguishing

performance ratings and are targeting applications similar to AFFF and/or AR-foams without using

fluoroorganic compounds. These foam concentrates are based upon mixtures of hydrocarbon

surface-active agents and non-fluorine containing stabilizers.

NOTE Fluorine free foams are currently not considered to provide an aqueous film.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

Annex B

(normative)

Sampling of foam concentrates

The samples for testing shall be delivered by the supplier in completely filled sealable containers. The

samples for testing shall be taken and delivered by the supplier using a method which provides a

representative sample of the foam concentrate to be tested.

NOTE Nominal 20-l containers are convenient.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

Annex C

(normative)

Determination of percentage sediment

C.1 Sampling

NOTE See Clause 4.

Use a sample prepared in accordance with Annex B. Place approximately 1 l of the sample in a suitable

container of nominal capacity sufficient to provide an ullage of 5 % to 10 % of the container volume. Seal

the container. Ensure that any sediment is dispersed evenly by agitating the sample container.

Take two samples, testing one immediately at a temperature of (20 ± 5) °C, the other after ageing for

(24 ± 2) h at (60 ± 2) °C in a completely filled container without access to air.

C.2 Apparatus

C.2.1 Graduated centrifuge tubes.

NOTE The centrifuge tubes described in ISO 3734 are suitable.

−2

C.2.2 Centrifuge, operating at (6 000 ± 600) m s .

NOTE The centrifuge described in ISO 3734 is suitable.

C.2.3 180 μm sieve conforming to ISO 3310-1.

C.2.4 Plastic wash bottle.

C.3 Procedure

C.3.1 Centrifuge each sample of the concentrate for 10 min. Determine the volume of the sediment and

report it as a percentage of the volume of the centrifuged sample.

C.3.2 Wash the contents of the centrifuge tube onto the sieve and check whether the sediment can be

dispersed through the sieve by the jet from the plastic wash bottle.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

Annex D

(normative)

Freezing point determination

D.1 General

NOTE See Clause 5.

This test is derived from the test procedure EN ISO 5764 “Freezing Point of Milk”.

D.2 Apparatus

D.2.1 Cooling bath capable of attaining temperatures below minus 30 °C;

D.2.2 250 ml vessel (double-neck flask or beaker) with stirrer;

D.2.3 Temperature measuring device, capable of electronic data read-out and accuracy of ±0,5 K;

NOTE Examples for a suitable device would be a Pt100 or a thermocouple type K, class 1.

D.2.4 XY-recorder for plotting a curve of temperature against time.

D.3 Procedure:

D.3.1 Fill (200 ± 10) ml sample into the 250 ml vessel.

D.3.2 Insert the stirrer and the temperature measuring device into vessel in such a way that the

temperature measuring device does not touch the stirrer, and is completely covered by liquid.

D.3.3 Insert the vessel into the cooling bath.

D.3.4 Start the stirrer, and adjust the speed so that the entire volume of liquid is slightly agitated, but

no air is drawn into the liquid.

D.3.5 Set the cooling bath temperature to (5 to 10) °C below the expected freeze point of the liquid.

D.3.6 Note the temperature, and plot a graph of temperature against time.

D.3.7 The temperature curve will drop until a certain point, then it will rise for a period before dropping

again.

D.3.8 The freezing point of the liquid is the highest point of this part of the graph, before the curve starts

to drop again.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

D.4 Example of a temperature against time curve for evaluation:

Key

X temperature

Y time

Figure D.1 — XY-Plotter (temperature against time curve)

Interpretation of the curve:

The obtained curve should look like as given in Figure D.1. The temperature drop is from right to left

(Axis X), the dashed line curve obtained from bath temperature and the solid line curve from the sample.

The slight temperature rise shown in the solid line curve is caused by the crystallization heat released by

the freezing out of the first component. The maximum (shown here as –10,2 °C) is to be recorded as the

freezing point.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

Annex E

(normative)

Determination of viscosity for pseudo-plastic foam concentrates

NOTE The measurement principle is described in EN ISO 3219-2.

E.1 Pseudo-plastic foam concentrates

Pseudo-plastic foam concentrates have a viscosity which decreases with increasing shear rate at constant

temperature.

NOTE Pseudo-plastic foam concentrates are a particular class of non-Newtonian foam concentrate.

E.2 Viscosity determination

E.2.1 Apparatus

E.2.1.1 Rotational viscometer in accordance with EN ISO 3219-2 with the following parameters:

— absolute measuring geometry according to EN ISO 3219-2:2021, 6.3.2;

— maximum shear stress ≥ 75 Pa;

−1

— maximum shear rate ≥ 600 s .

The viscometer shall be fitted with a temperature control unit which can maintain the sample

temperature within ± 1 °C of the required temperature.

NOTE An example for an absolute measuring geometry is the cone-plate measuring geometry.

E.2.2 Viscosity measurement

If the sample contains suspended air bubbles the sample shall be centrifuged for 10 min using the

apparatus specified in C.2.1 and C.2.2 before the sample is applied in the apparatus.

The test should be performed in accordance with the following test procedure:

1) adjustment of temperature control unit;

2) setting of the gap;

3) application of the sample;

4) wait to reach temperature equilibrium;

−1

5) 1 min pre-shearing at 600 s ;

6) 1 min waiting period without shearing;

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

-1 -1 -1 −1 -

7) measure the shear stress at least at the following 12 shear rates: 10 s , 20 s , 50 s , 75 s , 100 s

1 −1 −1 −1 −1 −1 −1 −1

, 150 s , 225 s , 300 s , 375 s , 450 s , 525 s , 600 s . Measure the shear stress for 10 s

at each shear rate.

8) Calculate the shear viscosity from Formula (E.1):

𝜏𝜏

𝜂𝜂 = 1 000 × (E.1)

𝛾𝛾̇

where

η is the shear viscosity in mPa⋅s;

τ is the shear stress in Pa;

-1

𝛾𝛾̇ is the shear rate in s .

9) Repetition of steps 1) to 8) for double determination and mean value calculation.

E.2.3 Results

−1

Report the results as a table including test temperature (°C), shear rate (s ), shear stress (Pa), shear

viscosity (mPa·s) and measuring geometry.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

Annex F

(normative)

Temperature conditioning of foam concentrates

F.1 General

If the foam concentrate is claimed by the supplier not to be adversely affected by storage at −30 °C,

condition the sample in accordance with Clause F.2 and then in accordance with Clause F.3; otherwise,

condition only in accordance with Clause F.3.

F.2 Low temperature conditioning

F.2.1 Apparatus

F.2.1.1 Freezing chamber, capable of achieving a temperature of (−30 ± 3) °C.

F.2.1.2 Sample containers, in accordance with Annex B.

NOTE More than one container can be needed to condition sufficient volume of foam concentrate for

subsequent testing.

F.2.2 Procedure

Set the temperature of the freezing chamber to (−30 ± 3) °C.

Do not agitate the content of the container(s) at any time until the sample of foam concentrate has been

divided into top and bottom half-samples (see Clause F.4).

Place the sample container(s) in the freezing chamber and maintain at the required temperature for

(24 ± 1) h. At the end of this period store the container(s) for not less than 48 h and not more than 96 h

in an ambient temperature of (20 ± 5) °C.

Repeat three times so that there are four cycles of freezing and thawing before testing.

F.3 High temperature conditioning

F.3.1 Apparatus

F.3.1.1 Oven, capable of achieving a temperature of (60 ± 3) °C.

F.3.2 Procedure

Set the temperature of the oven to (60 ± 3) °C.

If the foam concentrate sample has not been conditioned in accordance with Clause F.2 use foam

concentrate sample in accordance with Annex B; otherwise use containers conditioned in accordance

with Clause F.2. Do not agitate the content of the container(s) at any time until the sample of foam

concentrate has been divided into top and bottom half-samples (see Clause F.4).

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

Place the container(s) in the oven and maintain at the required temperature for 7 days. At the end of this

period store the container(s) for not less than 48 h and not more 96 h in an ambient temperature of

(20 ± 5) °C.

F.4 Division into top and bottom half-samples

F.4.1 Apparatus

F.4.1.1 Top half-sample container(s)

Sealable empty container(s), suitable for the foam concentrate to be tested, of minimum half the volume

of the sample container(s) as described in Annex B.

F.4.1.2 Divider device

After conditioning, the top sample from the sample container shall be divided from the bottom sample by

pressurizing the sample container and forcing the top sample through a delivery pipe into the top sample

container described in F.4.1.1. A principle sketch of the divider and sample container is shown in

Figure F.1.

The delivery pipe and the pressure inlet can be fitted to the lid of the original sample container. In practice

it might be necessary to use different fittings depending on the design of the lid and sample container. Be

sure that the fitting between divider and the lid is air tight to keep the pressure needed to force the foam

concentrate through the delivery pipe.

In order to ensure that there is no mixture between the top sample and the bottom sample during the

division process, the delivery pipe shall be adjustable in a vertical direction. The inlet of the delivery pipe

shall be conical and equipped with a plate in order to provide a horizontal flow into the pipe as shown in

Figure F.1. In order to make it possible to mount the delivery pipe either the cone and plate shall be

detachable or the delivery pipe shall be designed in a way that it can be mounted through the lid. Other

suitable design of the divider device is permitted provided that the function is the same.

oSIST prEN 1568-2:2025

prEN 1568-2:2025 (E)

Key

1 air pressure pipe

2 delivery pipe diameter (8 to 15) mm

3 detachable cone and plate, diameter (25 to 35) mm, height (40 to 50) mm, distance between cone and

plate (10 to 12) mm

4 sample container approximately 20 l

5 top sample

6 bottom sample

Figure F.1 — Example of a suitable equipment to divide the conditioned foam con

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...