EN 1650:2008+A1:2013

(Main + Amendment)Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of fungicidal or yeasticidal activity of chemical disinfectants and antiseptics used in food, industrial, domestic and institutional areas - Test method and requirements (phase 2, step 1)

Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of fungicidal or yeasticidal activity of chemical disinfectants and antiseptics used in food, industrial, domestic and institutional areas - Test method and requirements (phase 2, step 1)

This document specifies a test method and the minimum requirements for fungicidal or yeasticidal activity of chemical disinfectant and antiseptic products that form a homogeneous, physically stable preparation when diluted with hard water or - in the case of ready-to-use-products - with water. Products can only be tested at a concentration of 80 % or less as some dilution is always produced by adding the test organisms and interfering substance.

This document applies to products that are used in food, industrial, domestic and institutional areas excluding areas and situations where disinfection is medically indicated and excluding products used on living tissues except those for hand hygiene in the above considered areas. The following areas are at least included:

a) processing, distribution and retailing of:

1) food of animal origin: 2) food of vegetable origin:

- milk and milk products; - beverages;

- meat and meat products; - fruits, vegetables and derivatives (including sugar, distillery ...);

- fish, seafood, and related products; - flour, milling and baking;

- eggs and egg products; - animal feeds;

- animal feeds; - etc.

- etc.

b) institutional and domestic areas:

- catering establishments;

- public areas;

- public transports;

- schools;

- nurseries;

- shops;

- sports rooms;

- waste containers (bins ...);

- hotels;

- dwellings;

- clinically non-sensitive areas of hospitals;

- offices;

- etc.

c) other industrial areas:

- packaging material;

- biotechnology (yeast, proteins, enzymes, ...);

- pharmaceutical;

- cosmetics and toiletries;

- textiles;

- space industry, computer industry;

- etc.

EN 14885 specifies in detail the relationship of the various tests to one another and to use recommendations.

NOTE 1 The method described is intended to determine the activity of commercial formulations or active substances under the conditions in which they are used.

NOTE 2 This method corresponds to a phase 2 step 1 test.

Chemische Desinfektionsmittel und Antiseptika - Quantitativer Suspensionsversuch zur Bestimmung der fungiziden oder levuroziden Wirkung chemischer Desinfektionsmittel und Antiseptika in den Bereichen Lebensmittel, Industrie, Haushalt und öffentliche Einrichtungen - Prüfverfahren und Anforderungen (Phase 2, Stufe 1)

Dieses Dokument legt ein Prüfverfahren und die Mindestanforderungen an die fungizide oder levurozide Wirkung von chemischen Desinfektionsmitteln und Antiseptika fest, die in hartem Wasser oder im Fall gebrauchs¬fertiger Lösungen in Wasser eine homogene, physikalisch stabile Zubereitung bilden. Produkte können nur bis zu einer Konzentration von 80 % geprüft werden, da immer eine bestimmte Verdünnung durch Zugabe der Impfkultur oder der Belastungssubstanz erfolgt.

Dieses Dokument gilt für Produkte, die im Lebensmittelbereich, in der Industrie, im Haushalt und in öffentlichen Einrichtungen benutzt werden. Ausgenommen sind Bereiche und Situationen, in denen die Desinfektion medizinisch indiziert ist und Produkte, die auf lebenden Geweben benutzt werden, außer solchen, die zur Handhygiene in den oben genannten Bereichen verwendet werden. Die folgenden Bereiche sind mindestens eingeschlossen:

a) Verarbeitung, Vertrieb und Verkauf von:

1) Lebensmitteln tierischer Herkunft:

Milch und Milchprodukte;

Fleisch und Fleischprodukte;

Fisch, Meerestiere und daraus hergestellte Zubereitungen;

Eier und Eiprodukte;

Tiernahrung;

usw.

2) Lebensmitteln pflanzlicher Herkunft:

Getränke;

Früchte, Gemüse und daraus hergestellte Zubereitungen (einschließlich Zucker, Destillationsprodukte usw.);

Mehl, gemahlene und gebackene Produkte;

Tiernahrung;

usw.

b) öffentliche Einrichtungen und Haushaltsbereiche:

Verpflegungsbetriebe;

Öffentliche Bereiche;

Öffentliche Verkehrsmittel;

Schulen;

Kindergärten;

Geschäfte;

Sportstätten;

Abfallbehälter (Mülltonnen usw.);

Hotels;

Wohngebäude;

klinisch nicht relevante Bereiche in Krankenhäusern;

Büroräume;

usw.

c) andere industrielle Bereiche:

Packmaterial;

Biotechnologie (Hefe, Proteine, Enzyme usw.);

Hersteller von Pharmazeutika;

Hersteller von Kosmetika und Toilettenartikel;

Hersteller von Textilien;

Weltraumforschungsindustrie, Computerindustrie;

usw.

EN 14885 legt im Einzelnen die Beziehungen der verschiedenen Prüfungen untereinander und zu den „Anwendungsempfehlungen“ fest.

ANMERKUNG 1 Das beschriebene Verfahren dient dazu, die Aktivität handelsüblicher Zubereitungen oder Wirksubstanzen unter deren Anwendungsbedingungen zu bestimmen.

ANMERKUNG 2 Diese Methode entspricht einem Phase 2/Stufe 1-Verfahren.

Antiseptiques et désinfectants chimiques - Essai quantitatif de suspension pour l'évaluation de l'activité fongicide ou levuricide des antiseptiques et des désinfectants chimiques utilisés dans le domaine de l'agro-alimentaire, dans l'industrie, dans les domaines domestiques et en collectivité - Méthode d'essai et prescriptions (phase 2, étape 1)

Le présent document spécifie une méthode d'essai et les prescriptions minimales relatives à l'activité

fongicide ou levuricide des produits antiseptiques et désinfectants chimiques qui forment une préparation

homogène, physiquement stable, lorsqu'ils sont dilués dans l'eau dure ou - dans le cas de produits prêts à

l'emploi - dans l'eau. Les produits ne peuvent être soumis à l'essai qu'à la concentration de 80 % ou à des

concentrations inférieures, car l'ajout des microorganismes d'essai et de la substance interférente

s'accompagne forcément d'une dilution.

Le présent document s'applique aux produits qui sont utilisés dans les domaines alimentaire, industriel,

domestique et en collectivités à l'exclusion des domaines et des situations où la désinfection est

médicalement indiquée et à l'exclusion des produits utilisés sur les tissus vivants à l'exception de ceux utilisés

pour l'hygiène des mains dans les domaines considérés ci-dessus. Sont inclus au moins les domaines

suivants :

Kemična razkužila in antiseptiki - Kvantitativni suspenzijski preskus za vrednotenje fungicidnega delovanja ali delovanja kemičnih razkužil in antiseptikov na kvasovke v živilski in drugih industrijah, gospodinjstvu in javnih ustanovah - Preskusna metoda in zahteve (faza 2, stopnja 1) (vključno z dopolnilom A1)

Ta dokument določa preskusno metodo in minimalne zahteve za fungicidno delovanje ali delovanje kemičnih razkužil in antiseptikov na kvasovke, ki tvorijo homogen, fizikalno stabilen pripravek, če so razredčeni s trdo vodo oziroma, pri proizvodih, ki so pripravljeni za uporabo, z vodo. Proizvode je mogoče preskušati samo pri 80-odstotni ali nižji koncentraciji, ker dodajanje preskusnih organizmov in moteče snovi vedno povzroči razredčenje. Ta dokument velja za izdelke, ki se uporabljajo v živilski in drugih industrijah, gospodinjstvu in javnih ustanovah, izključeni pa so področja in primeri, ko obstajajo zdravstvene indikacije za dezinfekcijo ter izdelki, ki se uporabljajo na živih tkivih, razen tistih, ki se uporabljajo za higieno rok v zgoraj navedenih področjih. Naslednja področja so najmanj vključena:

a) predelava, distribucija in prodaja:

1) hrane živalskega izvora:

– mleko in mlečni izdelki;– meso in mesni izdelki;

– ribe, morski sadeži in podobno;

– jajca in jajčni izdelki;

– živalska krma;

– itn.

2) hrane rastlinskega izvora:

– napitki;

– sadje, zelenjava in derivati (vključno s sladkorjem, destilati ...);

– moka, mletje in peka;

– živalska krma;

– itn.

b) javne ustanove in gospodinjstva:

– priprava in dostava hrane;

– javne ustanove;

– javni prevozi;

– šole;

– vrtci;

– trgovine;

– športni objekti;

– zbiralniki odpadkov (koši ...);

– hoteli;

– bivališča;

– klinično neobčutljivi prostori bolnišnic;

– pisarne;

– itn.

c) druga industrijska področja:

– embalaža;

– biotehnologija (kvasovke, proteini, encimi ...);

– farmacevtski izdelki;

– kozmetični in toaletni izdelki;

– tkanine;

– vesoljska in računalniška industrija;

– itn.

EN 14885 podrobno določa razmerje med različnimi preskusi in priporočili za uporabo. OPOMBA 1: Opisana metoda je namenjena določevanju dejavnosti komercialnih oblik ali aktivnih snovi pod pogoji, v katerih se uporabljajo. OPOMBA 2: Ta metoda ustreza preskusu stopnje 1 faze 2.

General Information

- Status

- Withdrawn

- Publication Date

- 21-May-2013

- Withdrawal Date

- 03-Feb-2026

- Technical Committee

- CEN/TC 216 - Chemical disinfectants and antiseptics

- Drafting Committee

- CEN/TC 216/WG 3 - Food hygiene and domestic and institutional use

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 14-Aug-2019

- Completion Date

- 04-Feb-2026

Relations

- Effective Date

- 20-Mar-2013

- Effective Date

- 20-Mar-2013

- Effective Date

- 04-May-2016

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ECOCERT

Organic and sustainability certification.

Eurofins Food Testing Global

Global leader in food, environment, and pharmaceutical product testing.

Intertek Bangladesh

Intertek certification and testing services in Bangladesh.

Sponsored listings

Frequently Asked Questions

EN 1650:2008+A1:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of fungicidal or yeasticidal activity of chemical disinfectants and antiseptics used in food, industrial, domestic and institutional areas - Test method and requirements (phase 2, step 1)". This standard covers: This document specifies a test method and the minimum requirements for fungicidal or yeasticidal activity of chemical disinfectant and antiseptic products that form a homogeneous, physically stable preparation when diluted with hard water or - in the case of ready-to-use-products - with water. Products can only be tested at a concentration of 80 % or less as some dilution is always produced by adding the test organisms and interfering substance. This document applies to products that are used in food, industrial, domestic and institutional areas excluding areas and situations where disinfection is medically indicated and excluding products used on living tissues except those for hand hygiene in the above considered areas. The following areas are at least included: a) processing, distribution and retailing of: 1) food of animal origin: 2) food of vegetable origin: - milk and milk products; - beverages; - meat and meat products; - fruits, vegetables and derivatives (including sugar, distillery ...); - fish, seafood, and related products; - flour, milling and baking; - eggs and egg products; - animal feeds; - animal feeds; - etc. - etc. b) institutional and domestic areas: - catering establishments; - public areas; - public transports; - schools; - nurseries; - shops; - sports rooms; - waste containers (bins ...); - hotels; - dwellings; - clinically non-sensitive areas of hospitals; - offices; - etc. c) other industrial areas: - packaging material; - biotechnology (yeast, proteins, enzymes, ...); - pharmaceutical; - cosmetics and toiletries; - textiles; - space industry, computer industry; - etc. EN 14885 specifies in detail the relationship of the various tests to one another and to use recommendations. NOTE 1 The method described is intended to determine the activity of commercial formulations or active substances under the conditions in which they are used. NOTE 2 This method corresponds to a phase 2 step 1 test.

This document specifies a test method and the minimum requirements for fungicidal or yeasticidal activity of chemical disinfectant and antiseptic products that form a homogeneous, physically stable preparation when diluted with hard water or - in the case of ready-to-use-products - with water. Products can only be tested at a concentration of 80 % or less as some dilution is always produced by adding the test organisms and interfering substance. This document applies to products that are used in food, industrial, domestic and institutional areas excluding areas and situations where disinfection is medically indicated and excluding products used on living tissues except those for hand hygiene in the above considered areas. The following areas are at least included: a) processing, distribution and retailing of: 1) food of animal origin: 2) food of vegetable origin: - milk and milk products; - beverages; - meat and meat products; - fruits, vegetables and derivatives (including sugar, distillery ...); - fish, seafood, and related products; - flour, milling and baking; - eggs and egg products; - animal feeds; - animal feeds; - etc. - etc. b) institutional and domestic areas: - catering establishments; - public areas; - public transports; - schools; - nurseries; - shops; - sports rooms; - waste containers (bins ...); - hotels; - dwellings; - clinically non-sensitive areas of hospitals; - offices; - etc. c) other industrial areas: - packaging material; - biotechnology (yeast, proteins, enzymes, ...); - pharmaceutical; - cosmetics and toiletries; - textiles; - space industry, computer industry; - etc. EN 14885 specifies in detail the relationship of the various tests to one another and to use recommendations. NOTE 1 The method described is intended to determine the activity of commercial formulations or active substances under the conditions in which they are used. NOTE 2 This method corresponds to a phase 2 step 1 test.

EN 1650:2008+A1:2013 is classified under the following ICS (International Classification for Standards) categories: 71.100.35 - Chemicals for industrial and domestic disinfection purposes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1650:2008+A1:2013 has the following relationships with other standards: It is inter standard links to EN 1650:2008, EN 1650:2008/FprA1, EN 1650:2019, EN 14885:2022, EN 12353:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1650:2008+A1:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Chemische Desinfektionsmittel und Antiseptika - Quantitativer Suspensionsversuch zur Bestimmung der fungiziden oder levuroziden Wirkung chemischer Desinfektionsmittel und Antiseptika in den Bereichen Lebensmittel, Industrie, Haushalt und öffentliche Einrichtungen - Prüfverfahren und Anforderungen (Phase 2, Stufe 1)Antiseptiques et désinfectants chimiques - Essai quantitatif de suspension pour l'évaluation de l'activité fongicide ou levuricide des antiseptiques et des désinfectants chimiques utilisés dans le domaine de l'agro-alimentaire, dans l'industrie, dans les domaines domestiques et en collectivité - Méthode d'essai et prescriptions (phase 2, étape 1)Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of fungicidal or yeasticidal activity of chemical disinfectants and antiseptics used in food, industrial, domestic and institutional areas - Test method and requirements (phase 2, step 1)71.100.35Kemikalije za dezinfekcijo v industriji in domaChemicals for industrial and domestic disinfection purposesICS:Ta slovenski standard je istoveten z:EN 1650:2008+A1:2013SIST EN 1650:2008+A1:2013en,fr,de01-julij-2013SIST EN 1650:2008+A1:2013SLOVENSKI

STANDARDSIST EN 1650:20081DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1650:2008+A1

May 2013 ICS 71.100.35 Supersedes EN 1650:2008

English Version

Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of fungicidal or yeasticidal activity of chemical disinfectants and antiseptics used in food, industrial, domestic and institutional areas - Test method and requirements (phase 2, step 1)

Antiseptiques et désinfectants chimiques - Essai quantitatif de suspension pour l'évaluation de l'activité fongicide ou levuricide des antiseptiques et des désinfectants chimiques utilisés dans le domaine de l'agro-alimentaire, dans l'industrie, dans les domaines domestiques et en collectivité - Méthode d'essai et prescriptions (phase 2, étape 1)

Chemische Desinfektionsmittel und Antiseptika - Quantitativer Suspensionsversuch zur Bestimmung der fungiziden oder levuroziden Wirkung chemischer Desinfektionsmittel und Antiseptika in den Bereichen Lebensmittel, Industrie, Haushalt und öffentliche Einrichtungen - Prüfverfahren und Anforderungen (Phase 2, Stufe 1) This European Standard was approved by CEN on 5 April 2008 and includes Amendment 1 approved by CEN on 28 March 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1650:2008+A1:2013: E SIST EN 1650:2008+A1:2013

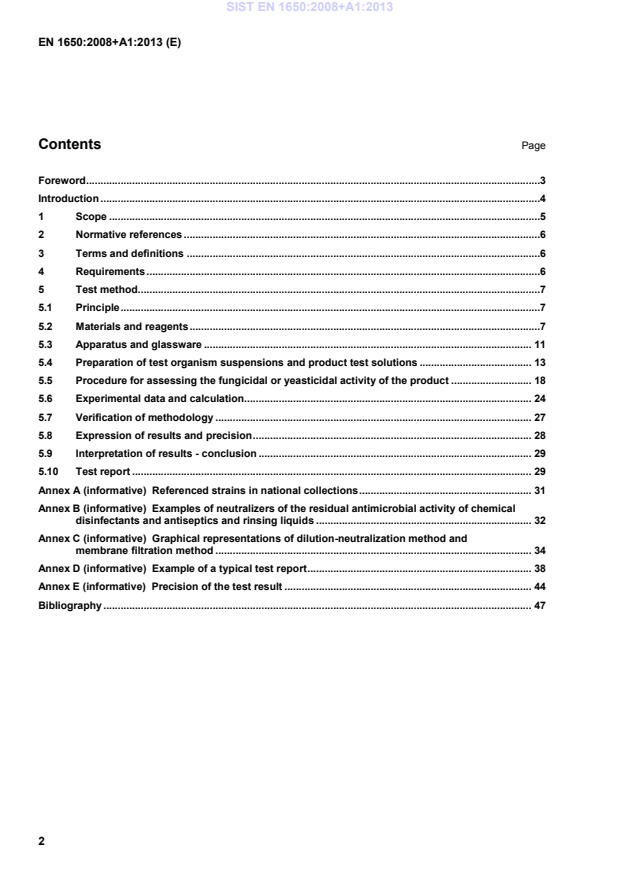

Referenced strains in national collections . 31 Annex B (informative)

Examples of neutralizers of the residual antimicrobial activity of chemical disinfectants and antiseptics and rinsing liquids . 32 Annex C (informative)

Graphical representations of dilution-neutralization method and membrane filtration method . 34 Annex D (informative)

Example of a typical test report . 38 Annex E (informative)

Precision of the test result . 44 Bibliography . 47

!". This European Standard was revised to include the results of a collaborative trial (ANDISTAND), to correct obvious errors and ambiguities, to harmonize the structure and wording with other quantitative suspension tests of CEN/TC 216 (existing or in preparation), and to improve the readability of the standard and thereby make it more understandable. According to the CEN/CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

The conditions are intended to cover general purposes and to allow reference between laboratories and product types. Each utilization concentration of the chemical disinfectant or antiseptic found by this test corresponds to defined experimental conditions. However, for some applications the recommendations of use of a product may differ and therefore additional test conditions should be used. SIST EN 1650:2008+A1:2013

a) processing, distribution and retailing of: 1) food of animal origin: 2) food of vegetable origin: milk and milk products; beverages; meat and meat products; fruits, vegetables and derivatives (including sugar, distillery .); fish, seafood, and related products; flour, milling and baking; eggs and egg products; animal feeds; animal feeds; etc. etc.

b) institutional and domestic areas: catering establishments; public areas; public transports; schools; nurseries; shops; sports rooms; waste containers (bins .); hotels; dwellings; clinically non-sensitive areas of hospitals; offices; etc. SIST EN 1650:2008+A1:2013

The fungicidal activity shall be evaluated using the following two test organisms:

Candida albicans (vegetative cells); SIST EN 1650:2008+A1:2013

NOTE For these additional conditions, the concentration defined as a result can be lower than the one obtained under the obligatory test conditions. 5 Test method 5.1 Principle 5.1.1 A sample of the product as delivered and/or diluted with hard water (or water for ready to use products) is added to a test suspension of fungi (yeast cells or mould spores) in a solution of an interfering substance. The mixture is maintained at (20 ± 1) °C for 15 min ± 10 s (obligatory test conditions). At the end of this contact time, an aliquot is taken, and the fungicidal and/or the fungistatic activity in this portion is immediately neutralized or suppressed by a validated method. The method of choice is dilution-neutralization. If a suitable neutralizer cannot be found, membrane filtration is used. The numbers of surviving fungi in each sample are determined and the reduction is calculated. 5.1.2 The test is performed using the vegetative cells of Candida albicans and the spores of Aspergillus niger (fungicidal activity) or only the vegetative cells of Candida albicans (yeasticidal activity) as test organisms (obligatory test conditions). 5.1.3 Additional and optional contact times and temperatures are specified. Additional test organisms can be used. 5.2 Materials and reagents 5.2.1 Test organisms The fungicidal activity shall be evaluated using the following strains as test organisms:1)

Candida albicans ATCC 10231 Aspergillus niger ATCC 16404

The yeasticidal activity shall be evaluated using only Candida albicans. NOTE See annex A for strain references in some other culture collections. The required incubation temperature for these test organisms is (30 ± 1) °C (5.3.2.3). If required for specific applications, additional strains may be chosen from, e.g. for breweries:

1) The ATCC numbers are the collection numbers of strains supplied by the American Type Culture Collection (ATCC). This information is given for the convenience of users of this standard and does not constitute an endorsement by CEN of the product named.

5.2.2 Culture media and reagents 5.2.2.1 General All weights of chemical substances given in this standard refer to the anhydrous salts. Hydrated forms may be used as an alternative, but the weights required shall be adjusted to allow for consequent molecular weight differences. The reagents shall be of analytical grade and/or appropriate for microbiological purposes. They shall be free from substances that are toxic or inhibitory to the test organisms. NOTE 1 To improve reproducibility, it is recommended that commercially available dehydrated material is used for the preparation of culture media. The manufacturer's instructions relating to the preparation of these products should be rigorously followed.

NOTE 2 For each culture medium and reagent, a limitation for use should be fixed. SIST EN 1650:2008+A1:2013

Malt extract

30,0 g

Agar

15,0 g

Water (5.2.2.2)

to 1 000,0 ml The malt extract should be food grade (e.g. Cristomalt powder from Difal) or equivalent that is not highly purified and not only based on maltose (e.g. Malt extract from OXOID) 1). However if there are problems producing at least 75 % spiny spores see 5.4.1.4.2.

Sterilize in the autoclave [5.3.2.1a)]. After sterilization, the pH of the medium shall be equivalent to 5,6 ± 0,2 when measured at (20 ± 1) °C. NOTE In case of encountering problems with neutralization (5.5.1.2 and 5.5.1.3), it may be necessary to add neutralizer to the MEA. Annex B gives guidance on the neutralizers that may be used.". 5.2.2.4 Diluent Tryptone sodium chloride solution, consisting of: Tryptone, pancreatic digest of casein

1,0 g Sodium chloride (NaCl)

8,5 g Water (5.2.2.2)

to 1 000,0 ml

Sterilize in the autoclave [5.3.2.1a)]. After sterilization, the pH of the diluent shall be equivalent to 7,0 ± 0,2 when measured at (20 ± 1) °C. 5.2.2.5 Neutralizer The neutralizer shall be validated for the product being tested in accordance with 5.5.1.2, 5.5.1.3 and 5.5.2. It shall be sterile. NOTE Information on neutralizers that have been found to be suitable for some categories of products is given in Annex B.

1) This information is given for the convenience of users of this European Standard and does not constitute an endorsement by CEN of the product named. Equivalent products may be used if they can be shown to lead to the same results. SIST EN 1650:2008+A1:2013

The hard water shall be freshly prepared under aseptic conditions and used within 12 h. NOTE When preparing the product test solutions (5.4.2), the addition of the product to the hard water produces a different final water hardness in each test tube. In any case the final hardness is lower than 300 mg/l of calcium carbonate (CaCO3) in the test tube. 5.2.2.8 Interfering substance 5.2.2.8.1 General The interfering substance shall be chosen according to the conditions of use laid down for the product. The interfering substance shall be sterile and prepared at 10 times its final concentration in the test. The ionic composition (e.g. pH, calcium and/or magnesium hardness) and chemical composition (e.g. mineral substances, protein, carbohydrates, lipids and detergents) shall be defined. NOTE The term “interfering substance” is used even if it contains more than one substance.

5.2.2.8.2 Clean conditions (bovine albumin solution – low concentration) Dissolve 0,3 g of bovine albumin fraction V (suitable for microbiological purposes) in 100 ml of water (5.2.2.2).

Sterilize by membrane filtration (5.3.2.7), keep in the refrigerator (5.3.2.8) and use within one month. The final concentration of bovine albumin in the test procedure (5.5) is 0,3 g/l. SIST EN 1650:2008+A1:2013

b) by dry heat, in the hot air oven [5.3.2.1b)]

2) Disposable sterile equipment is an acceptable alternative to reusable glassware. 3) Vortex® is an example of a suitable product available commercially. This information is given for the convenience of users of this standard and does not constitute an endorsement by CEN of this product. SIST EN 1650:2008+A1:2013

5.4 Preparation of test organism suspensions and product test solutions 5.4.1 Test organism suspensions (test and validation suspension) 5.4.1.1 General For each test organism, two different suspensions have to be prepared: the “test suspension” to perform the test and the “validation suspension” to perform the controls and method validation. 5.4.1.2 Preservation and stock cultures of test organisms The test organisms and their stock cultures shall be prepared and kept in accordance with EN 12353. 5.4.1.3 Working culture of test organisms 5.4.1.3.1 Candida albicans (yeast) In order to prepare the working culture of Candida albicans (5.2.1), prepare a subculture from the stock culture (5.4.1.2) by streaking onto MEA (5.2.2.3) slopes or plates (5.3.2.10) and incubate (5.3.2.3). After 42 h to 48 h, prepare a second subculture from the first subculture in the same way and incubate for 42 h to 48 h. From this second subculture, a third subculture may be produced in the same way. The second and (if produced) third subcultures are the working cultures. If it is not possible to prepare the second subculture on a particular day, a 72 h subculture may be used for subsequent subculturing, provided that the subculture has been kept in the incubator (5.3.2.3) during the 72 h period. Never produce and use a fourth subculture. ! 5.4.1.3.2 Aspergillus brasiliensis (previously A. niger) (mould) For Aspergillus brasiliensis (previously A. niger) (5.2.1), use only the first subculture grown on MEA (5.2.2.3) in Petri dishes or flasks with ventilated caps (5.3.2.14) and incubate for 7 d to 9 d. No further subculturing is needed. Do not stack the Petri dishes during the incubation to improve the temperature homogenization. At the end of incubation, all the cultures have to show a dark brown or black surface. Cultures with appearance of rare and small white or grey areas might be kept (see Figure 1).

Figure 1 — Photos N°1: A. brasiliensis ATCC 16404 after 7 d of incubation at 30 °C (right cultures)

Figure 2 — Photo N°2: A. brasiliensis ATCC 16404 after 7 d of incubation at 30 °C (wrong culture)" 5.4.1.3.3 Other test organisms (yeasts or moulds) For additional test organisms, any departure from this method of culturing the yeast or the mould or of preparing the suspensions shall be noted, giving the reasons in the test report. 5.4.1.4 Test suspension (“N”) 5.4.1.4.1 Candida albicans The procedure for preparing the Candida albicans test suspension is as follows. a) Take 10 ml of diluent (5.2.2.4) and place in a 100 ml flask with 5 g of glass beads (5.3.2.11). Take the working culture (5.4.1.3.1) and transfer loopfuls of the cells into the diluent (5.2.2.4). The cells should be suspended in the diluent by rubbing the loop against the wet wall of the flask to dislodge the cells before immersing in the diluent. Shake the flask for 3 min using a mechanical shaker [5.3.2.6b)]. Aspirate the suspension from the glass beads and transfer to another tube. b) Adjust the number of cells in the suspension to 1,5 x 107 cfu/ml4) to 5,0 x 107 cfu/ml using diluent (5.2.2.4), estimating the number of cfu by any suitable means. Maintain this test suspension in the water bath at the test temperature θ [5.5.1.1a)] and use within 2 h. NOTE The use of a spectrophotometer for adjusting the number of cells is highly recommended (approximately 620 nm wavelength — cuvette 10 mm path length). Each laboratory should therefore produce calibration data for

4) cfu/ml = colony-forming unit(s) per millilitre. SIST EN 1650:2008+A1:2013

Figure 3 — Photo N°3 Observation of conidiospores under light microscope: presence of smooth (a) and spiny (b) spores (wrong suspension)

Figure 4 — Photo N°4 Observation of conidiospores under light microscope: High concentration of characteristic mature spores with spiny aspect (right suspension)

c) Adjust the number of spores in the suspension to 1,5 x 107 cfu/ml to 5,0 x 107 cfu/ml using the diluent (5.2.2.4), estimating the number of cfu by any suitable means. Use the suspension within 4 h in a water bath controlled at 20 °C ± 1 °C (5.3.2.2). In any case, adjust the temperature according to 5.5.1.4 only immediately before the start of the test (5.5.2 or 5.5.3). The use of a cell counting device for adjusting the number of cells is highly recommended. When using a suitable counting chamber, it is essential to follow the instructions explicitly. Each laboratory should therefore produce calibration data to establish the relationship between the counts obtained using the counting device and the counts (5.4.1.6) obtained by the pour plate or the spread plate technique. Experienced laboratories found a better fit to the required number of spores when the spore suspension count in the device was 10 % to 50 % higher than the number aimed at. d) For counting, prepare 10-5 and 10-6 dilutions of the test suspension using diluent (5.2.2.4). Mix [5.3.2.6a)].

Take a sample of 1,0 ml of each dilution in duplicate and inoculate using the pour plate or thespread plate

technique. 1) When using the pour plate technique, transfer about half of each 1,0 ml sample into separate Petri dishes (i.e. in duplicate = four plates) and add 15 ml to 20 ml of melted MEA (5.2.2.3),cooled to

(45 ± 1) °C. 2) When using the spread plate technique, spread about one quarter of each 1,0 ml sample on an appropriate number (at least four) of surface dried plates containing MEA (5.2.2.3) (i.e. in duplicate – at least eight plates). For incubation and counting see 5.4.1.6." SIST EN 1650:2008+A1:2013

c) For incubation and counting, see 5.4.1.6. 5.4.1.6 Incubation and counting of the test and the validation suspensions For incubation and counting of the test and the validation suspensions, the procedure is as follows. a) Incubate (5.3.2.3) the plates for 42 h to 48 h. Discard any plates that are not countable for any reason. Count the cfu on the plates to determine the total number of cfu.

Only for Aspergillus niger incubate the plates for a further 20 h to 24 h and - if the number of colonies has increased - for a third additional period of 20 h to 24 h. Do not recount plates that no longer show well-separated colonies. Recount the remaining plates. If the number has increased, use only the higher number for further evaluation. b) Note for each plate the exact number of colonies, but record ">165" (for moulds) or ">330" (for yeasts) for any counts higher than 165 and 330 respectively and determine the Vc values according to 5.6.2.2. c) Calculate the numbers of cfu/ml in the test suspension “N” and in the validation suspension “Nv” using the methods given in 5.6.2.3 and 5.6.2.5. Verify according to 5.7. 5.4.2 Product test solutions

The concentration of a product test solution shall be 1,25 times the desired test concentration because it is diluted to 80 % during the test and the method validation (5.5.2 or 5.5.3). Product test solutions shall be prepared in hard water (5.2.2.7) at minimum three different concentrations to include one concentration in the active range and one concentration in the non-active range (5.8.2). The product as received may be used as one of the product test solutions, in this case the highest tested concentration is 80%.

Dilutions of ready-to-use products, i.e. products that are not diluted when applied, shall be prepared in water (5.2.2.2). For solid products, dissolve the product as received by weighing at least 1,0 g ± 10 mg of the product in a volumetric flask and filling up with hard water (5.2.2.7). Subsequent dilutions (lower concentrations) shall be prepared in volumetric flasks (5.3.2.12) on a volume/volume basis in hard water (5.2.2.7). For liquid products, dilutions of the product shall be prepared with hard water (5.2.2.7) on a volume/volume basis using volumetric flasks (5.3.2.12). The product test solutions shall be prepared freshly and used in the test within 2 h. They shall give a physically homogeneous preparation that is stable during the whole procedure. If during the procedure a visible inhomogeneity appears due to the formation of a precipitate or flocculant (for example, through the addition of the interfering substance), it shall be recorded in the test report. NOTE Counting micro-organisms embedded in a precipitate or flocculant is difficult and unreliable. The concentration of the product stated in the test report shall be the desired test concentration. Record the test concentration in terms of mass per volume or volume per volume and details of the product sample as received. SIST EN 1650:2008+A1:2013

additional temperatures may be chosen from 4 °C, 10 °C or 40 °C; the allowed deviation for each chosen temperature is ± 1 °C; b) contact time t (in min): the obligatory contact time to be tested is t = 15 min; additional contact times may be chosen from 1 min, 5 min, 30 min or 60 min; the allowed deviation for each chosen contact time is ± 10 s (except for 1 min: ± 5 s); c) interfering substance: the obligatory interfering substance to be tested is 0,3 g/l bovine albumin (5.2.2.8.2) for clean conditions or 3 g/l bovine albumin (5.2.2.8.3) for dirty conditions according to practical applications; additional interfering substances as given in 5.2.2.8 shall be chosen according to the field of application specified for the product; SIST EN 1650:2008+A1:2013

5.5.1.3 General instructions for validation and control procedures The neutralization and/or removal of the fungicidal and/or fungistatic activity of the product shall be controlled and validated - only for the highest product test concentration - for each of the used test organisms and for each experimental condition (interfering substance, temperature, contact time). These procedures (experimental condition control, neutralizer or filtration control and method validation) shall be performed at the same time with the test and with the same neutralizer – or rinsing liquid – used in the test. In the case of ready-to-use-products use water (5.2.2.2) instead of hard water. If because of problems with neutralization, a neutralizer has been added to MEA (5.5.1.2) used for the validation and control procedures the MEA used for the test shall contain the same amount of this neutralizer as well. 5.5.1.4 Equilibration of temperature Prior to testing, equilibrate all reagents (product test solutions (5.4.2), test suspension (5.4.1.4), validation suspension (5.4.1.5), diluent (5.2.2.4), hard water (5.2.2.7) and interfering substance (5.2.2.8) to the test temperature θ= [5.5.1.1a)] using the water bath (5.3.2.2) controlled at θ. Check that the temperature of the reagents is stabilized at θ. The neutralizer (5.2.2.5) or the rinsing liquid (5.2.2.6) and water (5.2.2.2) shall be equilibrated at a temperature of (20 ± 1) °C. In the case of ready-to-use-products, water (5.2.2.2) shall be additionally equilibrated to θ=.

5.5.1.5 Precautions for manipulation of test organisms Do not touch the upper part of the test tube sides when adding the test or the validation suspensions (5.4.1). 5.5.2 Dilution-neutralization method5)

5) For a graphical representation of this method see C.1. SIST EN 1650:2008+A1:2013

At the end of this time, add 8,0 ml of one of the product test solutions (5.4.2). Restart the stopwatch at the beginning of the addition. Mix [5.3.2.6a)] and place the tube in a water bath controlled at θ for the chosen contact time t [5.5.1.1b)]. Just before the end of t, mix [5.3.2.6a)] again. b) At the end of t, take a 1,0 ml sample of the test mixture "Na" and transfer into a tube containing 8,0 ml neutralizer (5.2.2.5) and 1,0 ml water (5.2.2.2). Mix [5.3.2.6a)] and place in a water bath controlled at (20 ± 1)°C. After a neutralization time of 5 min ± 10 s, mix and immediately take a sample of 1,0 ml of the neutralized test mixture "Na" (containing neutralizer, product test solution, interfering substance and test suspension) in duplicate and inoculate using the pour plate or spread plate technique. 1) When using the pour plate technique, pipette each 1,0 ml sample into separate Petri dishes and add 15 ml to 20 ml of melted MEA (5.2.2.3), cooled to (45 ± 1) °C.

2) When using the spread

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...