EN 16452:2015

(Main)Railway applications - Braking - Brake blocks

Railway applications - Braking - Brake blocks

This European Standard gives the requirements for the design, dimensions, performance, and testing of a brake block (otherwise known as brake shoe insert) that acts on the wheel tread as part of a tread brake system. This European Standard does not cover cast iron brake block requirements.

This European Standard is applicable to brake blocks of either "K", "L", or "LL" friction level designed to be fitted to tread braked rail vehicles.

This European Standard contains the requirements for interfacing the brake block with the rail vehicle, the testing procedures in order to confirm that it satisfies the basic safety and technical interchangeability requirements, the material control procedures to ensure product quality, reliability and conformity and considers health and environmental needs.

Bahnanwendungen - Bremse - Bremsklotzsohlen

Diese Europäische Norm enthält Anforderungen an Auslegung, Abmessungen, Leistung und Prüfung einer Bremsklotzsohle (auch bekannt als 'Bremsklotz'), die auf die Lauffläche als Teil eines Klotzbremssystems wirkt. Diese Norm behandelt keine Anforderungen an Bremsklotzsohlen aus Gusseisen.

Diese Europäische Norm ist für Bremsklotzsohlen der Reibungsklassen 'K', 'L', oder 'LL' anwendbar, die für den Einbau in Schienenfahrzeuge mit Klotzbremse ausgelegt sind.

Diese Norm enthält die Anforderungen für die Schnittstelle zwischen Bremsklotzsohle und Schienenfahrzeug, die Prüfverfahren zur Bestätigung, dass die grundlegenden Sicherheitsanforderungen und technischen Anfor¬derungen der Austauschbarkeit erfüllt werden, Kontrollverfahren für Werkstoffe zur Sicherstellung der Pro¬duktqualität, Funktionssicherheit und Konformität und berücksichtigt gesundheits- und umweltrelevante Bedürfnisse.

Applications ferroviaires - Freinage - Semelles de frein

La présente Norme européenne spécifie les exigences relatives à la conception, aux dimensions, aux performances et aux essais d’une semelle de frein (également appelée « semelle de freinage ») qui agit sur la table de roulement de la roue dans le cadre d’un système de frein sur roue. La présente Norme européenne ne traite pas des exigences relatives aux semelles de frein en fonte.

La présente Norme européenne s’applique aux semelles de frein à coefficient de frottement de niveau « K », « L » ou « LL » conçues pour être montées sur des véhicules ferroviaires à freins sur roue.

La présente Norme européenne spécifie les exigences relatives à l’interface de la semelle de frein avec le véhicule ferroviaire, les modes opératoires d’essai pour confirmer la satisfaction des exigences de base en matière de sécurité et d’interchangeabilité technique, les modes opératoires de contrôle des matériaux pour s’assurer de la qualité, de la fiabilité et de la conformité des produits, et tient compte des besoins en matière de santé et d'environnement.

Železniške naprave - Zavore - Zavorne ploščice

Ta evropski standard določa zahteve za zavorne ploščice, vključno z zahtevami za vmesnik, ki morajo biti konstrukcijsko izpolnjene, da je zagotovljen pravi torni material, zahtevami glede zmogljivosti, ki jih morajo izpolnjevati priklopniki in vozni park, ter zahtevami komercialnih testiranj in okoljskimi zahtevami, vključno z zahtevami za zmanjšanje hrupa. Ta evropski standard določa raven, odstopanja in povprečne ter takojšnje vedenje količnika trenja. Ta evropski standard zajema priporočila za nadzor proizvodnje, vključno s kontrolami izdelka in materiala. Ta evropski standard velja za kompozitne vstavke zavornih čeljusti pri železniških vozilih, ki so namenjeni namestitvi na železniška vozila javnih ali zasebnih podjetij, ki upravljajo z vlaki.

General Information

- Status

- Withdrawn

- Publication Date

- 30-Jun-2015

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 3/WG 47 - Braking

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 06-Mar-2019

- Completion Date

- 28-Jan-2026

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish national quality association.

Sponsored listings

Frequently Asked Questions

EN 16452:2015 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Braking - Brake blocks". This standard covers: This European Standard gives the requirements for the design, dimensions, performance, and testing of a brake block (otherwise known as brake shoe insert) that acts on the wheel tread as part of a tread brake system. This European Standard does not cover cast iron brake block requirements. This European Standard is applicable to brake blocks of either "K", "L", or "LL" friction level designed to be fitted to tread braked rail vehicles. This European Standard contains the requirements for interfacing the brake block with the rail vehicle, the testing procedures in order to confirm that it satisfies the basic safety and technical interchangeability requirements, the material control procedures to ensure product quality, reliability and conformity and considers health and environmental needs.

This European Standard gives the requirements for the design, dimensions, performance, and testing of a brake block (otherwise known as brake shoe insert) that acts on the wheel tread as part of a tread brake system. This European Standard does not cover cast iron brake block requirements. This European Standard is applicable to brake blocks of either "K", "L", or "LL" friction level designed to be fitted to tread braked rail vehicles. This European Standard contains the requirements for interfacing the brake block with the rail vehicle, the testing procedures in order to confirm that it satisfies the basic safety and technical interchangeability requirements, the material control procedures to ensure product quality, reliability and conformity and considers health and environmental needs.

EN 16452:2015 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering; 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16452:2015 has the following relationships with other standards: It is inter standard links to EN 16452:2015+A1:2019, EN ISO 21920-3:2022, EN 13452-1:2003, EN ISO 24478:2024, EN 14033-1:2017, EN 15313:2024, EN 15663:2017+A2:2024, EN 15179:2007, EN 14198:2016+A2:2021, EN 13715:2020, EN 13979-1:2003+A2:2011, EN 16185-1:2014+A1:2020, EN 16185-2:2014+A1:2019, EN 15734-2:2010+A1:2021, EN 14033-2:2008+A1:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16452:2015 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2008/57/EC, 96/48/EC; Standardization Mandates: M/275, M/334, M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16452:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bahnwendungen - Bremse - BremsklotzsohlenApplications ferroviaires - Freinage - Semelles de freinRailway applications - Braking - Brake blocks45.040Materiali in deli za železniško tehnikoMaterials and components for railway engineeringICS:Ta slovenski standard je istoveten z:EN 16452:2015SIST EN 16452:2015en,fr,de01-september-2015SIST EN 16452:2015SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16452

July 2015 ICS 45.040; 45.060.01 English Version

Railway applications - Braking - Brake blocks

Applications ferroviaires - Freinage - Semelles de frein

Bahnanwendungen - Bremse - Bremsklotzsohlen This European Standard was approved by CEN on 28 February 2015.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2015 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 16452:2015 ESIST EN 16452:2015

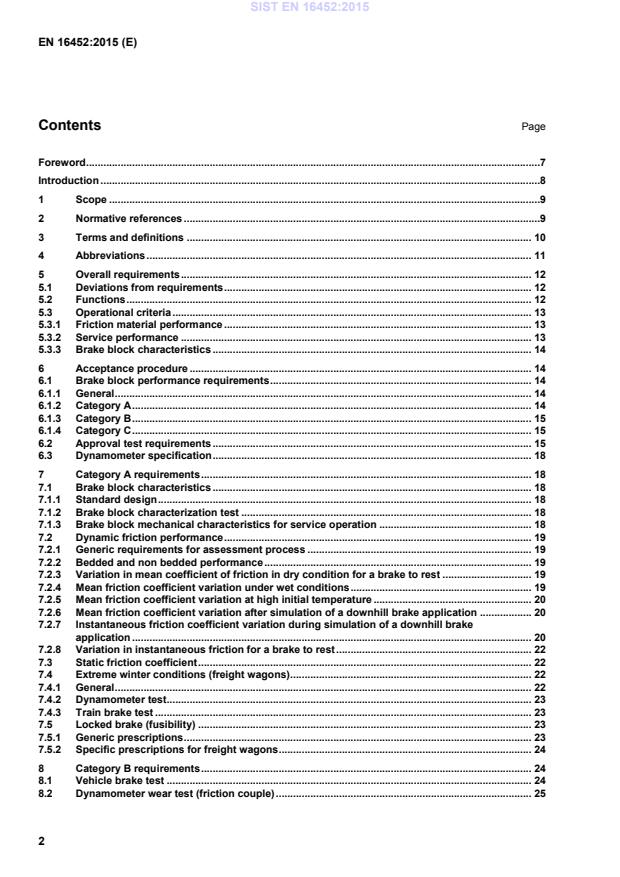

Summary of Dynamometer test programs and acceptance criteria . 28 Annex B (normative)

General requirements for conducting dynamometer test programmes . 30 B.1 General . 30 B.2 Rotation and ventilation conditions . 30 B.3 Brake application timing ts . 30 B.4 Bedding . 30 B.5 Wear . 30 B.6 Roughness index of the wheel tread . 31 B.7 Interruption of the tests . 31 B.8 Temperatures . 31 B.9 Wet conditions . 31 B.10 Test of simulation of downhill . 32 B.11 Test wheels . 32 Annex C (normative)

Composite brake blocks (K) (2Bg – 2Bgu)– Demonstration of friction properties for S and SS (S/SS) – braked freight wagons (vmax = 120 km/h) . 33 C.1 Program for performance tests . 33 C.2 Program for simulation brake assessment . 38 C.3 Dispersion range of mean friction coefficients . 39 C.4 Dispersion range of instantaneous friction coefficients . 42 Annex D (normative)

Composite brake blocks (LL) – Demonstration of friction properties for S and SS (S/SS) – braked freight wagons (vmax = 120 km/h) . 44 D.1 Program for performance tests . 44 D.2 Program for simulation brake assessment . 48 D.3 Dispersion range of mean friction coefficients . 50 D.4 Dispersion range of instantaneous friction coefficients . 52 Annex E (normative)

Composite brake blocks (K) (1Bg)– Demonstration of friction properties for S and SS (S/SS) – braked freight wagons (vmax = 120 km/h) . 53 E.1 Program for performance tests . 53 E.2 Dispersion range of mean friction coefficients . 56 SIST EN 16452:2015

Composite brake blocks (L) – Demonstration of friction properties for extra tread brake of coach . 59 F.1 Program for performance tests . 59 F.2 Program for simulation brake assessment . 62 F.3 Dispersion range of mean friction coefficients in dry condition . 63 F.4 Dispersion range of mean friction coefficients in wet condition . 64 F.5 Dispersion range of instantaneous friction coefficients . 65 Annex G (normative)

Composite brake blocks (K) – Demonstration of friction properties for locomotives . 67 G.1 Program for performance tests . 67 G.2 Program for simulation brake assessment . 70 G.3 Dispersion range of mean friction coefficients in dry condition . 71 G.4 Dispersion range of mean friction coefficients in wet condition . 72 G.5 Dispersion range of instantaneous friction coefficients . 73 Annex H (normative)

Composite brake blocks (K) – Demonstration of friction properties for EMU – DMU . 75 H.1 Program for performance tests . 75 H.2 Program for simulation brake assessment . 80 H.3 Dispersion range of mean friction coefficients in dry condition . 81 H.4 Dispersion range of mean friction coefficients in wet condition . 82 H.5 Dispersion range of instantaneous friction coefficients . 83 Annex I (normative)

Composite brake blocks (K) – Demonstration of friction properties for High speed train (motor bogie) . 85 I.1 Program for performance tests . 85 I.2 Program for simulation brake assessment . 88 I.3 Dispersion range of mean friction coefficients in dry condition . 89 I.4 Dispersion range of mean friction coefficients in wet condition . 91 I.5 Dispersion range of instantaneous friction coefficients . 92 Annex J (informative)

Dynamometer test program – Generic test program . 94 J.1 General . 94 J.2 Generic test program . 94 J.3 Definitions . 97 J.4 Principle of assessment and pass/fail criteria . 98 Annex K (normative)

Dynamometer Test program to detect the formation of metal pick-up at the brake block . 99 K.1 Test program for freight wagons with brake blocks type K and LL . 99 K.2 Test program for locomotives with brake blocks type K . 101 K.3 Test program for EMU – DMU with brake blocks type K . 103 K.4 Test program for High speed train with brake blocks type K . 106 SIST EN 16452:2015

Dynamometer test program to demonstrate the extreme winter braking properties . 109 L.1 Test program for freight wagons with brake blocks type K . 109 L.2 Test program for freight wagons with brake blocks type LL . 111 L.3 Specific requirements for conducting Test Programs L.1 and L.2 . 112 L.4 Process of assessment and past fail criteria for test programs L.1 and L.2 . 113 L.5 Generic flow chart to perform test program . 114 L.6 Detailed flow chart to perform test program (example brake block K) . 115 Annex M (normative)

Test run to demonstrate the extreme winter braking properties brake blocks K – LL for freight wagons . 118 M.1 General . 118 M.2 Test conditions . 118 M.3 Bases for assessment . 119 M.4 Assessment of measurement data and pass/fail criteria . 121 Annex N (normative)

Dynamometer Test program to simulate “Locked brake” . 123 N.1 Test program for freight wagons with brake blocks type K and LL . 123 N.2 Test program for locomotives with brake blocks type K . 124 N.3 Test program for EMU – DMU with brake blocks type K . 125 N.4 Test program for High speed train with brake blocks type K . 126 Annex O (normative)

Dynamometer test program to demonstrate the compatibility with track circuits . 127 O.1 General . 127 O.2 Short description of the measuring method used . 127 O.3 Schematic diagram of test set up . 127 O.4 Flow chart to perform test program . 129 O.5 Preparation of the disc and the rollers . 129 O.6 Preparation of the samples of brake block . 129 O.7 Contamination of disc . 130 O.8 Measurements . 131 O.9 Assessment of the results . 132 Annex P (informative)

Vehicle test to demonstrate the compatibility with track circuits . 134 P.1 General . 134 P.2 Test conditions . 134 P.3 Assessment of results . 135 P.4 Pass/fail criteria . 136 Annex Q (informative)

Dynamometer test program – Determination of static friction coefficient . 138 Q.1 Test program for freight wagons with brake blocks type K and LL . 138 Q.2 Test program for EMU – DMU and Locomotive with brake blocks type K . 139 Q.3 Test program for High speed train with brake blocks type K . 140 SIST EN 16452:2015

Dynamometer test program – Simulation of service conditions for freight wagons . 143 R.1 Simulation freight wagon with brake block type K 2Bgu . 143 R.2 Simulation freight wagon with brake block type LL 2Bgu . 145 Annex S (normative)

Interchangeability, rejection lugs and critical dimensions . 148 Annex T (normative)

Brake block shear and flexural strength tests . 151 T.1 General . 151 T.2 Shear strength test . 151 T.3 Flexural strength test . 152 Annex U (normative)

Limitation of permissible mechanical damage of brake block . 154 U.1 General . 154 U.2 Cracked through to back-plate . 154 U.3 Crumbling of the friction material . 155 U.4 Metal pick-up . 155 U.5 Detachment from back-plate . 156 U.6 Cracks in the direction of wheel circumference . 156 U.7 Detachment of the friction material . 156 U.8 Interface with the brake block holder . 156 Annex V (normative)

In service assessment of brake block . 158 V.1 General . 158 V.2 Freight wagon . 158 V.3 Coach . 159 V.4 Locomotive . 159 V.5 EMU-DMU . 160 V.6 High speed train . 160 V.7 Description of areas to be monitored and additional measures . 161 V.8 Pass/fail criteria . 162 Annex W (informative)

Complementary definitions and abbreviations . 163 Annex X (informative)

Brake block characterization test . 165 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2008/57/EC . 166 Bibliography . 169

3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 14478 and the following apply. 3.1 application parameter configuration parameters refer to vehicle mass, operating speed, wheel diameter, braked mass, brake block configuration, brake block force 3.2 Bg configuration one brake block 320 mm per brake block holder Note 1 to entry: Bg comes from UIC and means “Bremsklotzsohle geteilt”. 3.3 Bgu configuration two brake blocks 250 mm per brake block holder Note 1 to entry: Bgu comes from UIC and means “Bremse geteilt mit unterteilter Sohle”. 3.4 brake block stator part of a tread brake adapted to generate a friction force when engaged with a wheel tread 3.5 brake block force force with which the brake block is made to come into contact with the wheel tread 3.6 friction material consumable portion of the brake block that acts on the wheel tread in order to provide the specified brake performance 3.7 coefficient of friction 3.7.1 mean coefficient of friction coefficient of friction of the friction material, integrated over distance, for any one condition of braking SIST EN 16452:2015

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...