EN 1434-4:2015+A1:2018

(Main + Amendment)Thermal energy meters - Part 4: Pattern approval tests

Thermal energy meters - Part 4: Pattern approval tests

This European Standard specifies pattern approval tests for thermal energy meters. Thermal energy meters are instruments intended for measuring the energy which in a heat-exchange circuit is absorbed (cooling) or given up (heating) by a liquid called the heat-conveying liquid. The thermal energy meter indicates the quantity of heat in legal units.

Electrical safety requirements are not covered by this European Standard.

Pressure safety requirements are not covered by this European Standard.

Surface mounted temperature sensors are not covered by this European Standard.

This standard covers meters for closed systems only, where the differential pressure over the thermal load is limited.

Thermische Energiemessgeräte - Teil 4: Prüfungen für die Bauartzulassung

Diese Europäische Norm legt Prüfungen für die Bauartzulassungen für thermische Energiemessgeräte

fest. Thermische Energiemessgeräte sind Geräte, die dazu dienen, die Energiemenge zu messen, die in

einem Wärmeübertragerkreislauf durch eine als Wärmeträgerflüssigkeit bezeichnete Flüssigkeit

aufgenommen (Kühlen) oder abgegeben (Heizen) wird. Das thermische Energiemessgerät zeigt die

Wärmemenge in gesetzlichen Einheiten an.

Elektrische Sicherheitsanforderungen werden in dieser Europäischen Norm nicht behandelt.

Den Druck betreffende Sicherheitsanforderungen werden in dieser Europäischen Norm nicht behandelt.

Oberflächenmontierte Temperaturfühler werden in dieser Europäischen Norm nicht behandelt.

Die vorliegende Norm behandelt ausschließlich Zähler für geschlossene Systeme, in denen der Differenzdruck

über die Wärmemenge begrenzt ist.

Compteurs d'énergie thermique - Partie 4 : Essais en vue de l'approbation de modèle

La présente Norme européenne spécifie les essais en vue de l'approbation de modèle pour les compteurs d'énergie thermique. Les compteurs d'énergie thermique sont des instruments destinés à mesurer l'énergie thermique qui, dans un circuit d'échange thermique, est absorbée (refroidissement) ou cédée (chauffage) par un liquide appelé « liquide caloporteur ». Le compteur d'énergie thermique

fournit la quantité d'énergie thermique en unités de mesure légales.

La présente Norme européenne ne traite pas des prescriptions de sécurité électrique.

La présente Norme européenne ne traite pas des prescriptions de sécurité relative à la pression.

La présente Norme européenne ne traite pas des sondes de température montées en surface.

La présente norme couvre les compteurs pour les systèmes fermés uniquement, où la pression

différentielle dans la charge thermique est limitée.

Merilniki toplote - 4. del: Preskusi za odobritev tipa (vključno z dopolnilom A1)

Ta evropski standard določa preskuse za odobritev tipa merilnikov toplote. Merilniki toplote so instrumenti, namenjeni merjenju energije, ki jo v krogotoku toplotne izmenjave absorbira (hlajenje) ali oddaja (ogrevanje) tekočina, imenovana tekočina za prenos toplote. Merilnik toplote podaja toploto v predpisanih enotah.

Ta evropski standard ne zajema električnih varnostnih zahtev.

Ta evropski standard ne zajema tlačnih varnostnih zahtev.

Ta evropski standard ne zajema površinsko nameščenih senzorjev temperature.

Ta standard zajema samo števce za zaprte sisteme, kjer je diferencialni tlak nad toplotno obremenitvijo omejen.

General Information

- Status

- Withdrawn

- Publication Date

- 20-Nov-2018

- Withdrawal Date

- 03-Feb-2026

- Technical Committee

- CEN/TC 176 - Heat meters

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 07-Sep-2022

- Completion Date

- 04-Feb-2026

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 20-Jun-2018

- Effective Date

- 12-Jun-2019

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

EN 1434-4:2015+A1:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Thermal energy meters - Part 4: Pattern approval tests". This standard covers: This European Standard specifies pattern approval tests for thermal energy meters. Thermal energy meters are instruments intended for measuring the energy which in a heat-exchange circuit is absorbed (cooling) or given up (heating) by a liquid called the heat-conveying liquid. The thermal energy meter indicates the quantity of heat in legal units. Electrical safety requirements are not covered by this European Standard. Pressure safety requirements are not covered by this European Standard. Surface mounted temperature sensors are not covered by this European Standard. This standard covers meters for closed systems only, where the differential pressure over the thermal load is limited.

This European Standard specifies pattern approval tests for thermal energy meters. Thermal energy meters are instruments intended for measuring the energy which in a heat-exchange circuit is absorbed (cooling) or given up (heating) by a liquid called the heat-conveying liquid. The thermal energy meter indicates the quantity of heat in legal units. Electrical safety requirements are not covered by this European Standard. Pressure safety requirements are not covered by this European Standard. Surface mounted temperature sensors are not covered by this European Standard. This standard covers meters for closed systems only, where the differential pressure over the thermal load is limited.

EN 1434-4:2015+A1:2018 is classified under the following ICS (International Classification for Standards) categories: 17.200.10 - Heat. Calorimetry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1434-4:2015+A1:2018 has the following relationships with other standards: It is inter standard links to EN 1434-4:2015, EN 1434-4:2015/prA1, EN 1434-4:2022, EN ISO 4064-2:2025, EN 1434-5:2015+A1:2019, EN 1434-1:2015+A1:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1434-4:2015+A1:2018 is associated with the following European legislation: EU Directives/Regulations: 2014/32/EU; Standardization Mandates: M/441, M/541. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1434-4:2015+A1:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Thermische Energiemessgeräte - Teil 4: Prüfungen für die BauartzulassungCompteurs d'énergie thermique - Partie 4 : Essais en vue de l'approbation de modèleThermal energy meters - Part 4: Pattern approval tests17.200.10Toplota. KalorimetrijaHeat. CalorimetryICS:Ta slovenski standard je istoveten z:EN 1434-4:2015+A1:2018SIST EN 1434-4:2016+A1:2019en,fr,de01-marec-2019SIST EN 1434-4:2016+A1:2019SLOVENSKI

STANDARDSIST EN 1434-4:20161DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1434-4:2015+A1

November

t r s z ICS

s yä t r rä s r English Version

Thermal energy meters æ Part

vã Pattern approval tests Compteurs d 5énergie thermique æ Partie

v ã Essais en vue de l 5approbation de modèle

Wärmezähler æ Teil

vã Prüfungen für die Bauartzulassung This European Standard was approved by CEN on

w September

t r s w and includes Amendment

s approved by CEN on

s z July

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s v u væ vã t r s w ªA sã t r s z ESIST EN 1434-4:2016+A1:2019

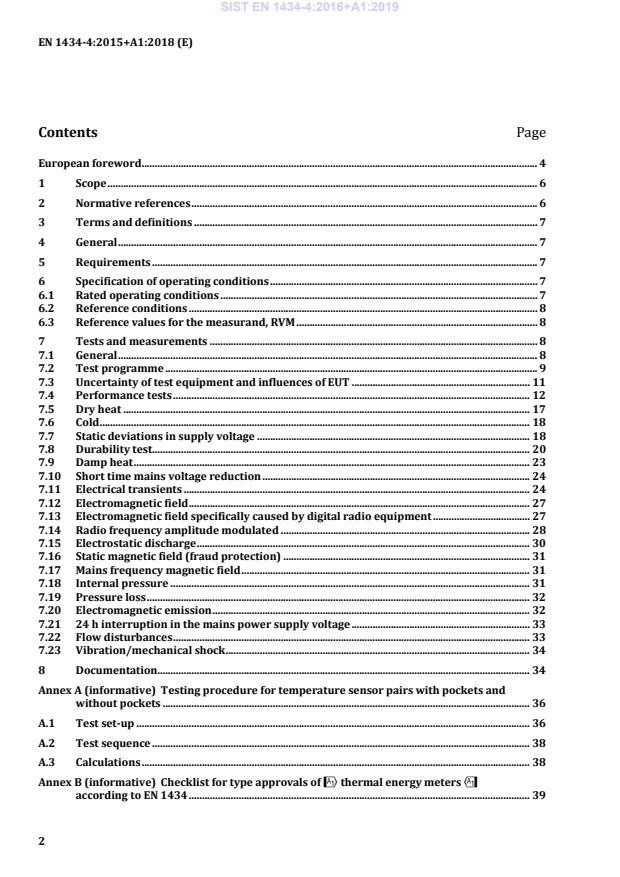

Testing procedure for temperature sensor pairs with pockets and without pockets . 36 A.1 Test set-up . 36 A.2 Test sequence . 38 A.3 Calculations . 38 Annex B (informative)

Checklist for type approvals of !thermal energy meters" according to EN 1434 . 39 SIST EN 1434-4:2016+A1:2019

Criteria for a fully developed flow profile . 56 Annex ZA (informative)

Relationship between this European Standard and the essential requirements of Directive 2014/32/EU aimed to be covered . 57 Bibliography . 58

«25 to +55 +5 to +55 Relative humidity in % < 93 Mains supply voltage in V 195 V to 253 V Mains frequency fnom ± 2 % Battery voltage The voltage of a battery in service under normal conditions Remote AC supply voltage 12 V to 36 V Remote DC supply voltage 12 V to 42 V Local external DC supply voltage As specified by manufacturer SIST EN 1434-4:2016+A1:2019

Heating applications Cooling applications Range of temperature difference: (40 ± 2) K

(10 ± 2) K Range of flow rate: (0,7 to 0,75) qp in m3/h (0,7 to 0,75) qp in m3/h Outlet temperature: (50 ± 5) °C (15 ± 5) °C The conditions, mentioned in Table 2, are reference values for a complete !thermal energy meter". Reference values for sub-assemblies are the relevant parts of the conditions mentioned in Table 2. Flow rate simulation for the flow sensor electronics is allowed, but testing with water is always preferred. The temperature of the liquid in the flow sensor shall be kept at (50 ± 5) °C or at ambient temperature. The power and signal wires shall be connected. The flow sensor including flow sensor electronics shall be operated at zero flow rate (without low flow cut off device). 7 Tests and measurements 7.1 General Unless otherwise stated in the test specification, the test requirements apply irrespective of the !thermal energy meter's" environmental class. See !EN 1434-1:2015+A1:2018, Clause 10". All measurements shall be carried out under the installation conditions stipulated by the manufacturer for his type of meter (e.g. straight sections of piping upstream and downstream of the meter). For all tests the heat conveying liquid shall be water, unless otherwise specified. The performance test shall be carried out with the specified liquid and the type approval certificate shall include the specification of the liquid to be used for initial verification. SIST EN 1434-4:2016+A1:2019

Influence factors

MPE 7.4 Performance test X X X X 2 MPE 7.5 Dry heat

Xa X X 2 MPE 7.6 Cold

Xa X X 2 MPE 7.7 Static deviations in supply voltage

Xa X X 2

Disturbances

NSFa 7.8 Durability X X

X 4 NSF 7.9.1 7.9.2 Damp heat, cyclic Damp heat, steady-state X Xc Xa Xc X

X X 1 1 NSF 7.10 Short time reduction in supply voltage

X X X 3 NSFa 7.11 Electrical transients

Xa,b Xb X 3 NSFd 7.12 Electromagnetic field

Xa,b Xb X 3 NSFd 7.13 Electromagnetic field – digital radio equipment

Xa,b Xb X 3 NSFd 7.14 Radio frequency, amplitude modulated

Xa,b Xb X 3 NSFa 7.15 Electrostatic discharge

Xa X X 3 NSFd 7.16 Static magnetic field

X X X 3 NSFd 7.17 Mains frequency magnetic field

Xa X X 3 SIST EN 1434-4:2016+A1:2019

X

X 1

7.19 Pressure loss

X

X 1

7.20 Electromagnetic emission

Xa Xb X 3

7.21 24 hrs interruption

X X 3 NSFd 7.22 Flow disturbances

X

X 1 NSFa 7.23 Vibration/ mechanical shock X X X X 2 MPE Maximum permissible error according to !EN 1434-1:2015+A1:2018, Clause 9". NSFd No signification fault shall occur during the test. NSFa No signification fault shall occur after the test. X Test to be performed. a Only for flow sensors with electronic devices. b This test shall be done with connected cables. c For cooling for meters / sub-assemblies with at least IP 65. For !bifunctional thermal energy meters" the tests in 7.4 shall cover both functions, the tests in 7.6 and 7.9 shall be carried out using the cooling function, but all other tests shall be carried out using the heating function. (For RVM values see 6.3.) 7.3 Uncertainty of test equipment and influences of EUT Standards, instruments and methods used in pattern approval tests shall suit the purpose, be traceable to more precise standards and be part of a reliable calibration programme. The uncertainties associated with these standards, methods and measuring instruments shall always be known. They shall be calculated with a coverage factor of 2 corresponding to a coverage probability of 95 %. The expanded uncertainties shall either: a) not exceed 1/5 of the maximum permissible errors of the !thermal energy meter" or the sub-assemblies, or b) if the uncertainty is higher than 1/5 of MPE, the value of the difference between uncertainty and 1/5 MPE shall be subtracted from MPE, to calculate a new reduced MPE. The use of a) is recommended. Uncertainty influences (combination of resolution and repeatability) coming from equipment under test shall not be more than 30 % for the flow sensor, 20 % for the calculator and 60 % for the temperature sensor pair of the MPE of each sub-assembly. SIST EN 1434-4:2016+A1:2019

Applications

Heating Cooling Test points All All

a minθ to minθ+ 5) °C (but not less than 10 °C) (15 ± 5) °C

b (50 ± 5) °C (5 ± 1) °C

c (85 ± 5) °C

The water temperature at the !thermal energy meter" shall not vary by more than 2 K during a measurement. SIST EN 1434-4:2016+A1:2019

If the manufacturer has stated a lower permitted conductivity, tests shall also be performed at that conductivity at the flow rates q1 and q5, and at the water temperature a). The conductivity shall be noted in the certificate. If the electronic part of the flow sensor is separated from the sensor head, the type and the maximum length of the connecting cable to the electrodes shall be stated by the manufacturer, be used for the above mentioned low conductivity test and noted in the certificate. 7.4.2.4 Fast response meters For fast response meters the transient behaviour of the flow sensors of size qp

¶ 2,5 m3/h shall be investigated by measuring the total quantity of water delivered in 10 to 15 cycles, consisting of 10 s period at a flow rate of qs and 30 s period at zero flow rate. The duration of start and stop shall be (1 ± 0,2) s. The water temperature shall be as a) in 7.4.2.2. The error shall not exceed the MPE. For a complete or combined meter, the water temperature specified above is the outlet temperature. The temperature difference shall be the maximum obtainable, but shall not exceed 42 K. 7.4.3 Calculator 7.4.3.1 Heating and cooling applications The calculator shall be tested at the following simulated temperatures: Table 5 — Testing temperatures for heating applications Temperature °C Temperature difference K a) ()5min0outletθθ+= min∆Θ, 5, 20, RVM∆Θ b) ()5outletRVMθθ=± min∆Θ, 5, 20, RVM∆Θ, max∆Θa c) ()0max5inletθθ−= 20, RVM∆Θ, max∆Θ a The level corresponding to max∆Θ shall be reduced if needed to be within maxθ. SIST EN 1434-4:2016+A1:2019

> hc and at inlet > hc; — cooling energy shall only be recorded at

< - hc and at inlet < hc; — no heating and cooling energies shall be recorded between - hc and hc. The general test in this clause shall be performed both for the heating and the cooling function using the correct heat coefficient (depending on installation of the flow sensor in higher respectively lower temperature). 7.4.3.2 Additional functionalities for smart metering applications 7.4.3.2.1 Internal clock as control quantity It shall be shown that the deviation from the official legal time during the whole estimated durability period does not exceed the optional values given in !EN 1434-1:2015+A1:2018, 5.10.5.1", means less than 1 h/year or less than 6 min or less than 7 s, by verifying the accuracy for setting the legal time or calculated evidence of deviation by the characteristics of the crystal frequency depending on e.g. temperature and time. By test for the accuracy of periodic interval registers for billing periods (e.g. hourly, daily, weekly or monthly registers), it shall be shown that the time deviation is not more than 1 % of the regarded period. This correct function of time as control quantity shall be tested at least three points of time within an appropriate period (e.g. 24 h), at a defined date. SIST EN 1434-4:2016+A1:2019

External digital signal as control quantity By tests of each additional register depending on the specific digital trigger signal (switching on/off), the correct activation of the specific additional accumulation register shall be proved. 7.4.3.2.3 Absolute temperature as control quantity 7.4.3.2.3.1 Single temperature sensor The compliance with the permissible error of the temperature sensor of ± 0,7 K compared to the performance curve according to EN 60751, including the signal cables thereof, shall be tested for each temperature sensor at three typical temperature points for field applications (e.g. 10 °C; 30 °C; 50 °C). 7.4.3.2.3.2 Calculator The compliance with the permissible error on temperature indication of the inlet and outlet temperatures compared to the correct value of the absolute temperature of ± 0,3 K shall be tested. This test shall be examined in relation to the value of the threshold temperature S used for activating the specific additional accumulation register at the range of ss5K5KsΘ−≤Θ≤Θ+=by=≤o×ble-si≤e≤=app±oaches=(inc±easing=an≤=≤ec±easing)=in=inc±ements=of=0,25=°C=via=the=pa±amete±ize≤=cont±ol=tempe±at×±e,=the=p±ope±=on/off-switching=f×nction=of=the=±espective=a≤≤itional=acc×m×lation=±egiste±=shall=be=p±ove≤.=7.4.3.2.3.3 Calculator with single temperature sensor The compliance with the permissible error on temperature indication of the inlet and outlet temperatures compared to the correct value of the absolute temperature of ± 1,0 K shall be tested. The test shall be examined in accordance with 7.4.3.2.3.2. NOTE In applications of smart metering, one or both single sensors of the pair are used as additional single sensor. 7.4.3.2.3.4 Communication interface Communication interfaces (e.g. electronic, optical, radio or other technical interface) shall be tested that the meter data correspond to the LCD contents. 7.4.4 Temperature sensors 7.4.4.1 Qualifying immersion depth It shall be verified in a thermostatic bath with a temperature of (85 ± 5) °C at an ambient temperature of (23 ± 2) °C, that a deeper immersion than the qualifying immersion depth changes the resistance value by an amount corresponding to < 0,1 K. 7.4.4.2 Thermal response time The temperature sensors shall be tested according to EN 60751:2008. For sensors designed to be mounted in pockets the test should be made with pockets using the set up defined in Annex A. The response time shall not exceed the manufacturer's specification. 7.4.4.3 General testing The temperature sensors of a pair shall be tested without their pockets at three temperature levels given in Table 7: SIST EN 1434-4:2016+A1:2019

Figure 1 — Basic wear test cycles with magnification of the first cycle The 100 continuous load changes are estimated for a durability period of 5 years. The durability period is scalable by its number of load cycles. Water quality is explained according to CEN/TR 16911. 7.8.2.3 Additional test The additional endurance test for long-life flow sensors shall have a duration of 500 h at a continuous flow rate equal to qs and at the upper limit of the temperature range. The additional test is estimated for an additional durability period of 5 years. The durability period is scalable by its number of hours. Water quality is explained according to CEN/TR 16911. Tolerance: 0s5q%−=SIST EN 1434-4:2016+A1:2019

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...