EN 15497:2014

(Main)Structural finger jointed solid timber - Performance requirements and minimum production requirements

Structural finger jointed solid timber - Performance requirements and minimum production requirements

This European Standard sets out provisions regarding the performance characteristics for structural finger jointed timber with rectangular cross section for use in buildings and bridges.

The use of structural finger jointed timber may be limited to certain service classes in some member states.

It also lays down minimum production provisions and procedures for Assessment and Verification of Constancy of Performance for structural finger jointed timber.

This European Standard is applicable to structural finger jointed timber made of coniferous timber species listed in this standard or poplar.

Although it may be possible to produce structural finger jointed timber made from specific broadleaf species based on some provisions of this European Standard, this standard is not applicable to these products.

This European Standard is only applicable to finger joints between timber sections of the same species.

This European Standard does not cover impressed (die-formed) finger joints.

This European Standard covers structural finger jointed timber untreated or treated against biological attack. Structural finger jointed timber treated with fire retardants is not covered.

Keilgezinktes Vollholz für tragende Zwecke - Leistungsanforderungen und Mindestanforderungen an die Herstellung

Diese Europäische Norm enthält Festlegungen hinsichtlich der Leistungsmerkmale von keilgezinktem Vollholz für tragende Zwecke mit rechteckigem Querschnitt zur Verwendung im Hoch- und Brückenbau.

ANMERKUNG Die Verwendung von keilgezinktem Vollholz für tragende Zwecke kann in einigen Mitgliedstaaten auf bestimmte Nutzungsklassen beschränkt sein.

Diese Norm enthält ebenfalls Mindestanforderungen an die Herstellung und Verfahren zur Bewertung und Überprüfung der Leistungsbeständigkeit von keilgezinktem Vollholz für tragende Zwecke.

Diese Europäische Norm gilt für keilgezinktes Vollholz für tragende Zwecke aus Nadelholzarten, die in dieser Norm aufgeführt sind, oder Pappelholz.

Obwohl auf der Grundlage einiger Festlegungen dieser Europäischen Norm keilgezinktes Vollholz für tragende Zwecke aus besonderen Laubholzarten hergestellt werden könnte, gilt diese Norm nicht für diese Produkte.

Diese Europäische Norm gilt nur für keilgezinktes Vollholz für tragende Zwecke derselben Holzart.

Keilzinkenverbindungen, die mit Pressverformung („die-formed“) hergestellt werden, sind in dieser Europäischen Norm nicht berücksichtigt.

Diese Europäische Norm gilt für unbehandeltes oder zum Schutz gegen biologischen Befall behandeltes keilgezinktes Vollholz für tragende Zwecke. Mit Flammschutzmitteln behandeltes keilgezinktes Vollholz für tragende Zwecke ist nicht Gegenstand dieser Norm.

Bois massif de structure à entures multiples - Exigences de performances et exigences minimales de fabrication

La présente Norme Européenne spécifie les exigences concernant les caractéristiques de performance du bois de structure avec aboutages à entures multiples de section rectangulaire destiné à être utilisé dans les bâtiments et les ponts.

Dans certains États Membres, l'utilisation de bois de structure avec aboutages à entures multiples peut être limitée à certaines classes de service.

Elle spécifie également les exigences minimales relatives à la fabrication ainsi que les procédures d'évaluation et de vérification de la constance des performances du bois de structure avec aboutages à entures multiples.

La présente Norme Européenne s'applique au bois de structure avec aboutages à entures multiples fabriqué à partir des essences de bois de résineux énumérées dans la présente Norme ou de peuplier.

Bien qu'il puisse être possible de fabriquer du bois de structure avec aboutages à entures multiples à partir d'essences de bois feuillus spécifiques en se basant sur certaines exigences de la présente Norme Européenne, celle-ci ne s'applique pas à ces produits.

La présente Norme Européenne s'applique uniquement aux aboutages à entures multiples entre des profilés en bois de même essence.

La présente Norme Européenne ne traite pas des aboutages emboutis.

La présente Norme Européenne s'applique au bois de structure avec aboutages à entures multiples non traité ou traité contre les attaques biologiques. Le bois de structure avec aboutages à entures multiples traité par des produits ignifuges n'est pas couvert.

Konstrukcijski zobato spojen masivni les - Zahteve za uporabo in minimalne zahteve za proizvodnjo

Standard EN 15497 podaja določbe v zvezi z zahtevami za uporabo konstrukcijskega zobato spojenega lesa s pravokotnim prečnim prerezom pri gradnji stavb in mostov. Uporaba konstrukcijskega zobato spojenega lesa je v nekaterih državah članicah morda omejena na določene razrede storitev. Standard prav tako podaja minimalne določbe za proizvodnjo in postopke za ocenjevanje in preverjanje nespremenljivosti lastnosti konstrukcijskega zobato spojenega lesa. Ta evropski standard velja za konstrukcijski zobato spojeni les, izdelan iz iglavcev, ki so navedeni v tem standardu, ali topolovine. Čeprav je na podlagi nekaterih določb tega evropskega standarda izdelava konstrukcijskega zobato spojenega lesa iz določenih listavcev mogoča, ta standard ne velja za te izdelke. Ta evropski standard velja samo za zobate spoje med lesenimi elementi iz iste vrste lesa. Ta standard ne zajema tlačno litih zobatih spojev. Ta evropski standard zajema zaščiten in nezaščiten konstrukcijski zobato spojeni les pred biološkimi dejavniki. Konstrukcijski zobato spojeni les, ki je obdelan z zaščitnimi sredstvi proti ognju, ni zajet.

General Information

- Status

- Published

- Publication Date

- 29-Apr-2014

- Technical Committee

- CEN/TC 124 - Timber structures

- Drafting Committee

- CEN/TC 124/WG 3 - Glued laminated timber

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 02-Dec-2025

- Completion Date

- 02-Dec-2025

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15497:2014 - Structural finger jointed solid timber - is a CEN European Standard that defines performance requirements and minimum production requirements for structural finger jointed timber with rectangular cross section for use in buildings and bridges. The standard applies to finger jointed timber made from listed coniferous species and poplar, and covers both untreated and timber treated against biological attack (but excludes products treated with fire retardants). EN 15497:2014 also sets out procedures for Assessment and Verification of Constancy of Performance (AVCP) including type testing and factory production control (FPC).

Key topics and requirements

- Scope and applicability: Structural finger jointed timber for load-bearing use in buildings and bridges; species limitations (conifers and poplar); excludes die‑formed (impressed) finger joints and finger joints between different species.

- Performance characteristics: Mechanical resistance (timber strength and bending strength of finger joints), bonding strength and durability of adhesives, resistance and reaction to fire, formaldehyde emissions, and release/content of dangerous substances.

- Adhesives and bond testing: Requirements for adhesive selection and specific test methods for bonding strength and long-term performance under variable climates and loads.

- Durability: Provisions for untreated and preservative-treated structural finger jointed timber against biological attack; note that fire-retardant-treated products are not covered.

- Production requirements: Minimum production provisions addressing personnel, facilities, equipment, finger geometry, moisture control, bonding surface, pressure and curing.

- AVCP and FPC: Procedures for type testing, sampling, reporting, factory production control, initial inspection, continuous surveillance and modification procedures.

- Marking and labelling: Requirements for product identification and performance declaration as part of conformity assessment.

Applications

EN 15497:2014 is used to ensure that structural finger jointed timber performs reliably in load-bearing applications such as:

- Structural beams, posts and members in buildings

- Bridge components where finger jointed solid timber is specified

- Components used in engineered timber products (e.g., glued solid timber, elements feeding into glulam or CLT production)

Who should use this standard

- Timber manufacturers and production managers (for compliance and FPC)

- Structural engineers and architects (for specifying compliant materials)

- Testing laboratories and certification bodies (for AVCP/type testing)

- Regulators and procurement authorities assessing product conformity with EU Construction Products Regulation (Regulation (EU) No 305/2011)

Related standards

- EN 14080:2013 (glued laminated timber - related product standards)

- EN 385:2001 (superseded by EN 15497:2014)

- Relevant EN test methods and CPR guidance referenced in Annex ZA

EN 15497:2014 provides the technical and procedural framework to specify, test and produce reliable structural finger jointed timber in line with European regulatory requirements.

Frequently Asked Questions

EN 15497:2014 is a standard published by the European Committee for Standardization (CEN). Its full title is "Structural finger jointed solid timber - Performance requirements and minimum production requirements". This standard covers: This European Standard sets out provisions regarding the performance characteristics for structural finger jointed timber with rectangular cross section for use in buildings and bridges. The use of structural finger jointed timber may be limited to certain service classes in some member states. It also lays down minimum production provisions and procedures for Assessment and Verification of Constancy of Performance for structural finger jointed timber. This European Standard is applicable to structural finger jointed timber made of coniferous timber species listed in this standard or poplar. Although it may be possible to produce structural finger jointed timber made from specific broadleaf species based on some provisions of this European Standard, this standard is not applicable to these products. This European Standard is only applicable to finger joints between timber sections of the same species. This European Standard does not cover impressed (die-formed) finger joints. This European Standard covers structural finger jointed timber untreated or treated against biological attack. Structural finger jointed timber treated with fire retardants is not covered.

This European Standard sets out provisions regarding the performance characteristics for structural finger jointed timber with rectangular cross section for use in buildings and bridges. The use of structural finger jointed timber may be limited to certain service classes in some member states. It also lays down minimum production provisions and procedures for Assessment and Verification of Constancy of Performance for structural finger jointed timber. This European Standard is applicable to structural finger jointed timber made of coniferous timber species listed in this standard or poplar. Although it may be possible to produce structural finger jointed timber made from specific broadleaf species based on some provisions of this European Standard, this standard is not applicable to these products. This European Standard is only applicable to finger joints between timber sections of the same species. This European Standard does not cover impressed (die-formed) finger joints. This European Standard covers structural finger jointed timber untreated or treated against biological attack. Structural finger jointed timber treated with fire retardants is not covered.

EN 15497:2014 is classified under the following ICS (International Classification for Standards) categories: 79.040 - Wood, sawlogs and sawn timber. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15497:2014 has the following relationships with other standards: It is inter standard links to EN 385:2001, EN 14081-1:2005+A1:2011, EN 13501-1:2018, EN 717-1:2004, EN 15416-3:2025, EN 1995-1-1:2025, EN 408:2010+A1:2012, EN 302-1:2023, EN 14358:2016, EN 302-2:2013, EN 336:2013, EN 301:2013, EN 13823:2020+A1:2022, EN 13501-2:2023, EN 302-3:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15497:2014 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/112. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15497:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Konstrukcijski zobato spojen masivni les - Zahteve za uporabo in minimalne zahteve za proizvodnjoKeilzinkenverbindungen im Bauholz - Leistungsanforderungen und Mindestanforderungen an die HerstellungBois massif de structure à entures multiples - Exigences de performances et exigences minimales de fabricationStructural finger jointed solid timber - Performance requirements and minimum production requirements79.040Les, hlodovina in žagan lesWood, sawlogs and sawn timberICS:Ta slovenski standard je istoveten z:EN 15497:2014SIST EN 15497:2014en,fr,de01-julij-2014SIST EN 15497:2014SLOVENSKI

STANDARDSIST EN 385:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15497

April 2014 ICS 79.040 Supersedes EN 385:2001English Version

Structural finger jointed solid timber - Performance requirements and minimum production requirements

Bois massif de structure à entures multiples - Exigences de performances et exigences minimales de fabrication

Keilgezinktes Vollholz für tragende Zwecke - Leistungsanforderungen und Mindestanforderungen an die Herstellung This European Standard was approved by CEN on 6 February 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15497:2014 ESIST EN 15497:2014

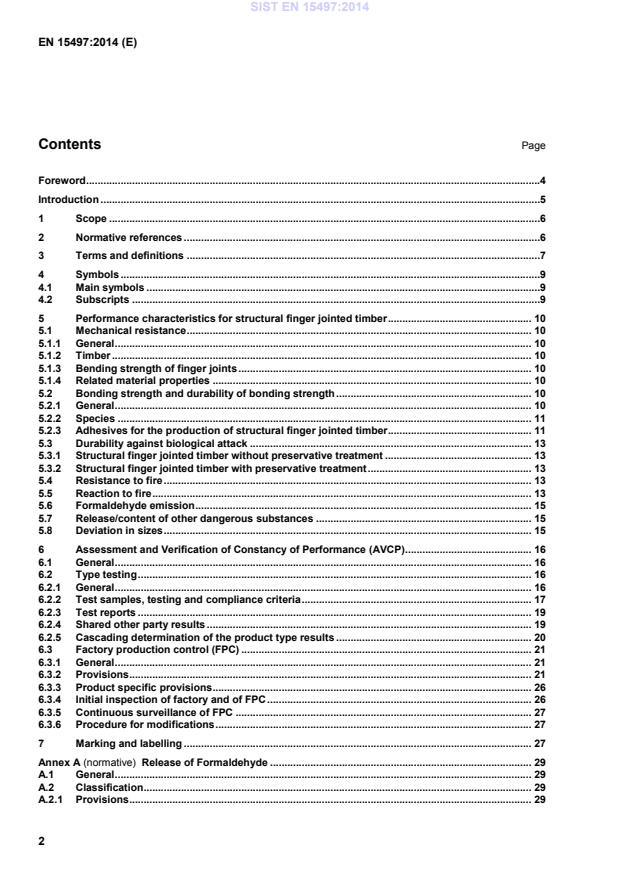

Release of Formaldehyde . 29 A.1 General . 29 A.2 Classification . 29 A.2.1 Provisions . 29 SIST EN 15497:2014

Additional test methods and provisions for adhesives . 31 B.1 General . 31 B.2 Long-term sustained load test at cyclic climate conditions with specimens loaded perpendicular to the glue line for moisture curing one-component polyurethane and emulsion polymer isocyanate adhesives. 31 B.2.1 General description . 31 B.2.2 Production of the specimens . 31 B.2.3 Test procedure and climate conditions . 32 B.2.4 Provisions . 33 B.2.5 Report . 33 Annex C (normative)

Bending tests with finger joints (including compliance criteria) . 34 C.1 Sampling. 34 C.1.1 General . 34 C.1.2 For type testing . 34 C.1.3 For factory production control . 34 C.2 Testing . 34 C.2.1 General . 34 C.2.2 Additional provisions for type testing . 34 C.2.3 Additional provisions for factory production control . 34 C.3 Compliance criteria . 35 C.3.1 For type testing . 35 C.3.2 For factory production control . 35 C.4 Report . 35 Annex D (normative)

Measurement of moisture content . 37 D.1 General . 37 D.2 Measurement of moisture content of timber during production . 37 D.3 Mean moisture content of structural finger jointed timber . 37 Annex E (normative)

Equipment . 38 Annex F (normative)

Separation tests with finger joints produced with contact-free application of adhesive . 39 Annex G (normative)

Minimum production provisions . 40 G.1 Personnel . 40 G.2 Production and storage facilities . 40 G.2.1 General . 40 G.2.2 Facilities for drying and storage of timber . 40 G.2.3 Facilities for processing and storage of adhesives . 40 G.2.4 Facilities for production and curing . 40 G.3 Equipment . 40 G.4 Finger joints . 41 G.4.1 Wane and edge damages. 41 G.4.2 Finger joint geometry . 42 G.4.3 Knots, local grain deviations and fissures . 42 G.4.4 Moisture content at bonding . 43 G.4.5 Bonding surface and application of the adhesive . 43 G.4.6 Time between cutting and adhesive application . 44 G.4.7 Pressure . 44 G.4.8 Curing . 45 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of EU Construction Products Regulation . 46 Bibliography . 57

Key 1 boards 6 glued laminated timber (glulam) 2 is a component for 7 glulam with large finger joints 3 structural finger jointed timber 8 block glued glulam 4 glued laminated products 9 cross laminated timber (X-Lam) 5 glued solid timber 10 cross laminated timber (X-Lam) with large finger joints Figure 1 — Relation of European Standards for structural timber products prepared by CEN/TC 124 SIST EN 15497:2014

Key 1 slot base lj finger length p pitch . finger angle lt tip gap bcut tip width of the cutter bt tip width Figure 2 — Typical profile of a finger joint 3.4 finger length distance between the finger base and the tip of the finger, measured along the centre line of the finger Note 1 to entry: See Figure 2. 3.5 manufacturer specific strength class set of characteristic strength, stiffness and density properties declared by a manufacturer 3.6 minimum mean density required mean density at reference moisture content Note 1 to entry: Minimum mean density is used for the classification of the reaction to fire. 3.7 pitch distance between centres of adjacent finger tips Note 1 to entry: See Figure 2. 3.8 ratio of resin to hardener proportion of resin and hardener by mass with the resin set at 100 parts 3.9 reduction factor ratio between tip width and pitch Note 1 to entry: See Figure 2. SIST EN 15497:2014

Adhesive type Treatment Type I Type II A1 9,5 9,5 A2 5,5 5,5 A3 7,6 7,6 A4 5,5 NR a A5 7,6 NR a A6 NR a 8,3 A7 7,2 NR a a Treatment cycle not required (NR).

1) A Commission´s decision on the applicability of Table 2 for structural finger jointed timber has been filed. SIST EN 15497:2014

Applies to all species covered by the product standards. b

Conditioned according to EN 13238. c

Class as provided for in Table 1 of the Annex to Decision 2000/147/EC.

When reaction to Fire is determined by testing the product shall be tested according to EN 13823 (SBI test) and mounted and fixed in accordance with the following: — the whole area of both wings in the SBI apparatus shall be covered with pieces of structural flinger jointed timber mounted edge to edge (butt jointed), without jointing or bonding and orientated horizontally or vertically; — supported by battens of the product concerned of a size minimum (40 × 80) mm, fixed to the test backing boards at 400 mm to 600 mm centres horizontally or vertically (perpendicular to the orientation of the product pieces), so that the resulting spacing between backing board and product is 80 mm; see also Figure 3. NOTE Test results are valid for finger jointed structural timber having at least the density and the minimum overall thickness of the specimens tested.

2) This table is the same as given in the Decision of the Commission 2003/593/EC of 2003-08-07 (see OJEU L201 of 2003-08-08). SIST EN 15497:2014

Key 400 mm ≤ d ≤ 600 mm 1 backing board 2 structural finger jointed timber 3 batten (cross section: 40 mm x 80 mm) Figure 3 — Top view of fixing system for reaction to fire test according to EN 13823 5.6 Formaldehyde emission The release of formaldehyde shall be declared as Class E1 or E2 according to Annex A. NOTE Products of Class E2 are banned in some Member States. 5.7 Release/content of other dangerous substances National regulations on dangerous substances may require verification and declaration on release and sometimes on content of other dangerous substances in addition to those dealt with in other clauses when construction products covered by this European Standard are placed on those markets. In the absence of European harmonized tests methods verification and declaration on release/content should be done taking into account national provisions in the place of use. NOTE An informative database covering European and national provisions on dangerous substances is available at the Construction website on EUROPA accessed through: http://ec.europa.eu/enterprise/construction/cpd-ds/. 5.8 Deviation in sizes The corrected sizes shall be calculated according to EN 336. They shall not deviate from the nominal width and thickness by more than the permissible deviations of the declared tolerance class given in EN 336. SIST EN 15497:2014

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...