ASTM D2276-22

(Test Method)Standard Test Method for Particulate Contaminant in Aviation Fuel by Line Sampling

Standard Test Method for Particulate Contaminant in Aviation Fuel by Line Sampling

SIGNIFICANCE AND USE

5.1 This test method provides a gravimetric measurement of the particulate matter present in a sample of aviation turbine fuel by line sampling. The objective is to minimize these contaminants to avoid filter plugging and other operational problems. Although tolerable levels of particulate contaminants have not yet been established for all points in fuel distribution systems, the total contaminant measurement is normally of most interest. The Appendix X1 color rating method is useful for fuel system monitoring purposes. No quantitative relationship exists between gravimetric and color rating test results.

SCOPE

1.1 This test method covers the determination of particulate contaminant in aviation turbine fuel using a field monitor.

1.2 There are two test methods described. The basic test method is used to evaluate the level of contamination gravimetrically. The second test method, presented in Appendix X1, describes a color rating technique that is used for rapid qualitative assessment of changes in contamination level without the time delay required for the gravimetric determinations by stringent laboratory procedures.

1.3 There are two Annexes and two Appendixes in this test method.

1.3.1 Annex A1 provides some precautionary information regarding the use of the required reagents.

1.3.2 Annex A2 describes a standard practice for obtaining a sample of the particulates present in a flowing stream of aviation turbine fuel.

1.3.3 Appendix X1 describes a test method for rating the particulate level in an aviation turbine fuel on the basis of the color of a filter membrane after sampling the fuel in the field.

1.3.4 Appendix X2 provides some safety precautions to avoid static discharge resulting from the accumulation of electrical charges in the fuel and on the equipment while following the procedures.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

- Status

- Published

- Publication Date

- 30-Jun-2022

- Technical Committee

- D02 - Petroleum Products, Liquid Fuels, and Lubricants

- Drafting Committee

- D02.J0.05 - Fuel Cleanliness

- Current Stage

Relations

- Effective Date

- 15-Mar-2024

- Refers

ASTM D4175-23a - Standard Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants - Effective Date

- 15-Dec-2023

- Effective Date

- 01-Nov-2023

- Effective Date

- 01-Oct-2023

- Refers

ASTM D4175-23e1 - Standard Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants - Effective Date

- 01-Jul-2023

- Effective Date

- 01-Jan-2018

- Effective Date

- 01-Dec-2017

- Effective Date

- 01-Dec-2016

- Effective Date

- 01-Sep-2016

- Effective Date

- 01-Jun-2016

- Effective Date

- 01-Oct-2015

- Effective Date

- 01-Sep-2015

- Effective Date

- 01-Aug-2015

- Effective Date

- 15-Jul-2015

- Effective Date

- 01-Jul-2015

ASTM D2276-22 - Standard Test Method for Particulate Contaminant in Aviation Fuel by Line Sampling

REDLINE ASTM D2276-22 - Standard Test Method for Particulate Contaminant in Aviation Fuel by Line Sampling

Frequently Asked Questions

ASTM D2276-22 is a standard published by ASTM International. Its full title is "Standard Test Method for Particulate Contaminant in Aviation Fuel by Line Sampling". This standard covers: SIGNIFICANCE AND USE 5.1 This test method provides a gravimetric measurement of the particulate matter present in a sample of aviation turbine fuel by line sampling. The objective is to minimize these contaminants to avoid filter plugging and other operational problems. Although tolerable levels of particulate contaminants have not yet been established for all points in fuel distribution systems, the total contaminant measurement is normally of most interest. The Appendix X1 color rating method is useful for fuel system monitoring purposes. No quantitative relationship exists between gravimetric and color rating test results. SCOPE 1.1 This test method covers the determination of particulate contaminant in aviation turbine fuel using a field monitor. 1.2 There are two test methods described. The basic test method is used to evaluate the level of contamination gravimetrically. The second test method, presented in Appendix X1, describes a color rating technique that is used for rapid qualitative assessment of changes in contamination level without the time delay required for the gravimetric determinations by stringent laboratory procedures. 1.3 There are two Annexes and two Appendixes in this test method. 1.3.1 Annex A1 provides some precautionary information regarding the use of the required reagents. 1.3.2 Annex A2 describes a standard practice for obtaining a sample of the particulates present in a flowing stream of aviation turbine fuel. 1.3.3 Appendix X1 describes a test method for rating the particulate level in an aviation turbine fuel on the basis of the color of a filter membrane after sampling the fuel in the field. 1.3.4 Appendix X2 provides some safety precautions to avoid static discharge resulting from the accumulation of electrical charges in the fuel and on the equipment while following the procedures. 1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 5.1 This test method provides a gravimetric measurement of the particulate matter present in a sample of aviation turbine fuel by line sampling. The objective is to minimize these contaminants to avoid filter plugging and other operational problems. Although tolerable levels of particulate contaminants have not yet been established for all points in fuel distribution systems, the total contaminant measurement is normally of most interest. The Appendix X1 color rating method is useful for fuel system monitoring purposes. No quantitative relationship exists between gravimetric and color rating test results. SCOPE 1.1 This test method covers the determination of particulate contaminant in aviation turbine fuel using a field monitor. 1.2 There are two test methods described. The basic test method is used to evaluate the level of contamination gravimetrically. The second test method, presented in Appendix X1, describes a color rating technique that is used for rapid qualitative assessment of changes in contamination level without the time delay required for the gravimetric determinations by stringent laboratory procedures. 1.3 There are two Annexes and two Appendixes in this test method. 1.3.1 Annex A1 provides some precautionary information regarding the use of the required reagents. 1.3.2 Annex A2 describes a standard practice for obtaining a sample of the particulates present in a flowing stream of aviation turbine fuel. 1.3.3 Appendix X1 describes a test method for rating the particulate level in an aviation turbine fuel on the basis of the color of a filter membrane after sampling the fuel in the field. 1.3.4 Appendix X2 provides some safety precautions to avoid static discharge resulting from the accumulation of electrical charges in the fuel and on the equipment while following the procedures. 1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM D2276-22 is classified under the following ICS (International Classification for Standards) categories: 75.160.20 - Liquid fuels. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D2276-22 has the following relationships with other standards: It is inter standard links to ASTM D1655-24, ASTM D4175-23a, ASTM D4865-23, ASTM D1655-23a, ASTM D4175-23e1, ASTM D1655-18, ASTM D1655-17a, ASTM D1655-16c, ASTM D1655-16b, ASTM D1655-16, ASTM D1655-15d, ASTM D6615-15a, ASTM D2244-15a, ASTM D1655-15b, ASTM D6615-15. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM D2276-22 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2276 − 22

Designation: 216/05 (2005)

Standard Test Method for

1,2

Particulate Contaminant in Aviation Fuel by Line Sampling

This standard is issued under the fixed designation D2276; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of particulate

responsibility of the user of this standard to establish appro-

contaminant in aviation turbine fuel using a field monitor.

priate safety, health, and environmental practices and deter-

1.2 There are two test methods described. The basic test

mine the applicability of regulatory limitations prior to use.

method is used to evaluate the level of contamination gravi-

1.6 This international standard was developed in accor-

metrically.Thesecondtestmethod,presentedinAppendixX1,

dance with internationally recognized principles on standard-

describes a color rating technique that is used for rapid

ization established in the Decision on Principles for the

qualitative assessment of changes in contamination level with-

Development of International Standards, Guides and Recom-

out the time delay required for the gravimetric determinations

mendations issued by the World Trade Organization Technical

by stringent laboratory procedures.

Barriers to Trade (TBT) Committee.

1.3 There are twoAnnexes and twoAppendixes in this test

2. Referenced Documents

method.

1.3.1 Annex A1 provides some precautionary information

2.1 ASTM Standards:

regarding the use of the required reagents.

D1193Specification for Reagent Water

1.3.2 Annex A2 describes a standard practice for obtaining

D1535Practice for Specifying Color by the Munsell System

a sample of the particulates present in a flowing stream of

D1655Specification for Aviation Turbine Fuels

aviation turbine fuel.

D2244Practice for Calculation of Color Tolerances and

1.3.3 Appendix X1 describes a test method for rating the

Color Differences from Instrumentally Measured Color

particulate level in an aviation turbine fuel on the basis of the

Coordinates

color of a filter membrane after sampling the fuel in the field.

D4175Terminology Relating to Petroleum Products, Liquid

1.3.4 Appendix X2 provides some safety precautions to

Fuels, and Lubricants

avoid static discharge resulting from the accumulation of

D4865Guide for Generation and Dissipation of Static Elec-

electrical charges in the fuel and on the equipment while

tricity in Petroleum Fuel Systems

following the procedures.

D5452Test Method for Particulate Contamination in Avia-

tion Fuels by Laboratory Filtration

1.4 The values stated in SI units are to be regarded as the

D6615Specification for Jet B Wide-Cut Aviation Turbine

standard. The values given in parentheses are for information

Fuel

only.

3. Terminology

This test method is under the jurisdiction of ASTM International Committee

3.1 Definitions:

D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct

3.1.1 For definitions of terms used in this test method, refer

responsibility ofASTM Subcommittee D02.J0.05 on Fuel Cleanliness. The techni-

to Terminology D4175.

cally equivalent standard as referenced is under the jurisdiction of the Energy

Institute Subcommittee SC-B-11.

3.2 Definitions of Terms Specific to This Standard:

This test method has been approved by the sponsoring committees and accepted

3.2.1 membrane color, n—a visual rating of particulate on a

by the Cooperating Societies in accordance with established procedures.

filter membrane against ASTM Color Standards.

Current edition approved July 1, 2022. Published September 2022. Originally

approved in 1964. Last previous edition approved in 2014 as D2276–06 (2014).

DOI: 10.1520/D2276-22.

2 3

This test method has been developed through the cooperative effort between For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ASTMandtheEnergyInstitute,London.ASTMandIPstandardswereapprovedby contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ASTMandEItechnicalcommitteesasbeingtechnicallyequivalentbutthatdoesnot Standards volume information, refer to the standard’s Document Summary page on

imply both standards are identical. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2276 − 22

3.2.2 membrane filter, n—a porous article of closely con-

trolled pore size through which a liquid is passed to separate

matter in suspension.

3.2.2.1 Discussion—RR:D02-1012 contains information

on membrane filters that meet the requirements therein.

3.2.3 monitor, n—something that reminds or warns.

3.2.3.1 Discussion—A plastic holder for a membrane filter

held in a field sampling apparatus.

3.2.4 particulate, adj—of or relating to minute separate

particles.

3.2.4.1 Discussion—Solids generally composed of oxides,

silicates, and fuel insoluble salts.

3.2.5 volatile fuels, n—relativelywideboilingrangevolatile

distillate.

3.2.5.1 Discussion—These are identified as Jet B in Speci-

fication D6615 or the military grade known as JP-4.

4. Summary of Test Method

4.1 Aknownvolumeoffuelisfilteredthroughapreweighed

test membrane filter in a field monitor and the increase in

membrane filter mass determined after washing and drying.

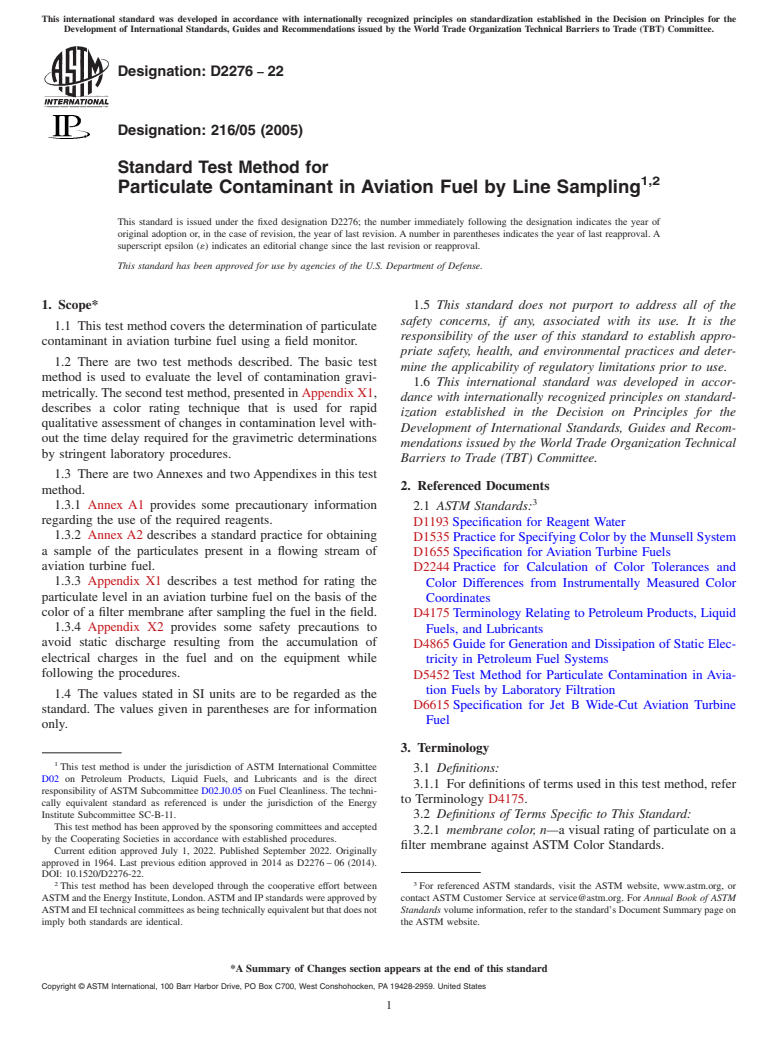

FIG. 1 Apparatus for Filtering and Dispensing Flushing Fluid

The change in mass of a control membrane filter located

immediatelybelowthetestmembranefilterisalsodetermined.

6. Apparatus

Theobjectiveofusingacontrolmembraneistoassesswhether

6.1 Analytical Balance, single- or double-pan, the precision

the fuel itself influences the weight of a membrane. The

standard deviation of which must be 0.07 mg or better.

particulate contaminant is determined from the increase in

mass of the test membrane filter relative to the control

6.2 Oven, of the static type (without fan-assisted air

membrane filter.

circulation), controllable to 90°C 6 5°C.

4.2 This test method employs a field monitor to filter a

6.3 Petri Dishes, approximately 125 mm in diameter with

sample of fuel that is taken in the field by the sampling

removable glass supports for membrane filters.

procedure detailed in Annex A2.

6.4 Forceps, flat-bladed with unserrated, non-pointed tips.

4.3 For situations where it is not possible to take a field

6.5 Vacuum System.

monitor sample, procedures are given in Test Method D5452

4,5

6.6 Test Membrane Filters, plain, 37mm diameter,

for the determination of particulate contaminant in a fuel

nominal pore size 0.8 µm (see Note 1).

sample by laboratory filtration.

4,5

6.7 Control Membrane Filters, 37mmdiameter,nominal

4.4 Appendix X1 describes a method for color-rating used

pore size 0.8 µm. (Gridded control membrane filters may be

filter membranes.

used for purpose of identification.)

5. Significance and Use

NOTE 1—Matched weight membrane filters, 37mm diameter, nominal

pore size 0.8 µm, may be used as test and control membrane filters if so

5.1 Thistestmethodprovidesagravimetricmeasurementof

desired. Use of matched-weight membrane filters precludes the necessity

the particulate matter present in a sample of aviation turbine

for carrying out subsequently the procedures detailed in Section 8.

fuel by line sampling. The objective is to minimize these

6.8 Dispenser for Flushing Fluid,0.45µmmembranefilters

contaminants to avoid filter plugging and other operational

to be provided in the delivery line (see Fig. 1). Alternatively,

problems. Although tolerable levels of particulate contami-

flushing fluid that has been pre-filtered through a 0.45 µm

nants have not yet been established for all points in fuel

membrane before delivery to the dispenser flask is acceptable.

distribution systems, the total contaminant measurement is

6.9 Field Monitors, complete with protective plugs and

normally of most interest. The Appendix X1 color rating

34mm support pads.

method is useful for fuel system monitoring purposes. No

quantitative relationship exists between gravimetric and color

6.10 Air Ionizer, for the balance case (see Note 2 and Note

rating test results.

3).

NOTE 2—When using a solid-pan balance, the air ionizer may be

Supportingdata(andalistofsupplierswhohaveprovideddataindicatingtheir

membranes, field monitors, and field monitor castings) have been filed at ASTM All available membrane filters are not suitable for this application. Apparatus

International Headquarters and may be obtained by requesting Research Report considered for this application shall be checked by the user for suitability in

RR:D02-1012. Contact ASTM Customer Service at service@astm.org. accordance with the requirements of RR:D02-1012, 1994 revision.

D2276 − 22

7.5 Flushing Fluids:

7.5.1 Petroleum Spirit (also known as petroleum ether or IP

Petroleum Spirit 40/60) (Warning—Extremely flammable.

Harmful if inhaled. Vapors are easily ignited by electrostatic

discharges, causing flash fire. See A1.2.), having boiling range

from 35°C to 60°C.

8. Preparation of Test and Control Membrane Filters

and Field Monitors Prior to Sampling

8.1 Two 37mm membrane filters of nominal pore size

0.8µm are required: a test and a control membrane filter.

Matched-weight membrane filters may be used if so desired

(seeNote1).Ifmatched-weightmembranefiltersareused,itis

unnecessary to carry out the procedures detailed in this section

because they have been carried out previously by the mem-

FIG. 2 Field Monitor Flushing Apparatus brane filter supplier. The two membrane filters used for each

individual test should be identified by marking the petri dishes

usedascontainers.Glasswareusedinpreparationofmembrane

omitted provided that, when weighing a membrane filter, it is placed on

filters shall be cleaned as described in Section 10.

the pan so that no part protrudes over the edge of the pan.

NOTE 3—Air ionizers should be replaced within 1 year of manufacture. 8.1.1 Using forceps, place the test and control membrane

filters side by side in a clean petri dish. To facilitate handling

6.11 Multimeter/VOM, used for determining whether elec-

the membrane filters should rest on clean glass support rods in

trical continuity is 10Ω or less between 2 points.

the petri dish.

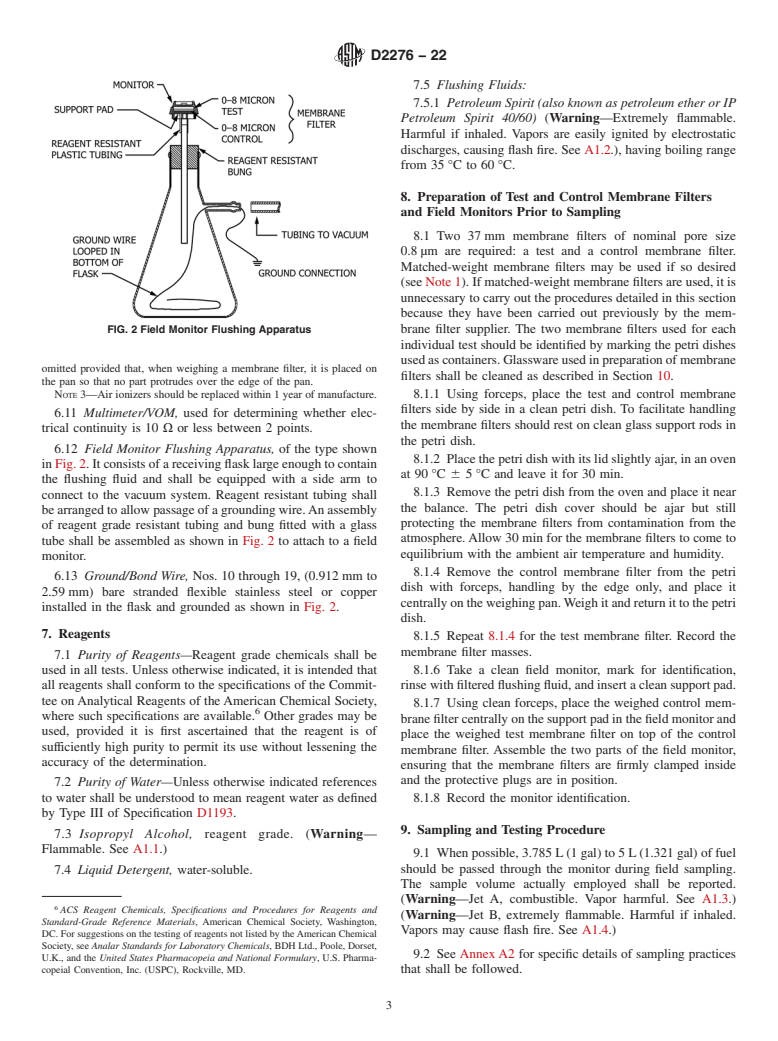

6.12 Field Monitor Flushing Apparatus, of the type shown

8.1.2 Placethepetridishwithitslidslightlyajar,inanoven

inFig.2.Itconsistsofareceivingflasklargeenoughtocontain

at 90°C 6 5°C and leave it for 30 min.

the flushing fluid and shall be equipped with a side arm to

8.1.3 Remove the petri dish from the oven and place it near

connect to the vacuum system. Reagent resistant tubing shall

the balance. The petri dish cover should be ajar but still

bearrangedtoallowpassageofagroundingwire.Anassembly

protecting the membrane filters from contamination from the

of reagent grade resistant tubing and bung fitted with a glass

atmosphere.Allow 30 min for the membrane filters to come to

tube shall be assembled as shown in Fig. 2 to attach to a field

equilibrium with the ambient air temperature and humidity.

monitor.

8.1.4 Remove the control membrane filter from the petri

6.13 Ground/Bond Wire, Nos. 10 through 19, (0.912mm to

dish with forceps, handling by the edge only, and place it

2.59mm) bare stranded flexible stainless steel or copper

centrallyontheweighingpan.Weighitandreturnittothepetri

installed in the flask and grounded as shown in Fig. 2.

dish.

7. Reagents

8.1.5 Repeat 8.1.4 for the test membrane filter. Record the

membrane filter masses.

7.1 Purity of Reagents—Reagent grade chemicals shall be

8.1.6 Take a clean field monitor, mark for identification,

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit- rinsewithfilteredflushingfluid,andinsertacleansupportpad.

tee onAnalytical Reagents of theAmerican Chemical Society,

8.1.7 Using clean forceps, place the weighed control mem-

where such specifications are available. Other grades may be

branefiltercentrallyonthesupportpadinthefieldmonitorand

used, provided it is first ascertained that the reagent is of

place the weighed test membrane filter on top of the control

sufficiently high purity to permit its use without lessening the

membrane filter. Assemble the two parts of the field monitor,

accuracy of the determination.

ensuring that the membrane filters are firmly clamped inside

and the protective plugs are in position.

7.2 Purity of Water—Unless otherwise indicated references

to water shall be understood to mean reagent water as defined

8.1.8 Record the monitor identification.

by Type III of Specification D1193.

9. Sampling and Testing Procedure

7.3 Isopropyl Alcohol, reagent grade. (Warning—

Flammable. See A1.1.)

9.1 Whenpossible,3.785L(1gal)to5L(1.321gal)offuel

7.4 Liquid Detergent, water-soluble. should be passed through the monitor during field sampling.

The sample volume actually employed shall be reported.

(Warning—Jet A, combustible. Vapor harmful. See A1.3.)

ACS Reagent Chemicals, Specifications and Procedures for Reagents and

(Warning—Jet B, extremely flammable. Harmful if inhaled.

Standard-Grade Reference Materials, American Chemical Society, Washington,

Vapors may cause flash fire. See A1.4.)

DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

9.2 See AnnexA2 for specific details of sampling practices

U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

copeial Convention, Inc. (USPC), Rockville, MD. that shall be followed.

D2276 − 22

TABLE 1 Statistical Information for Particulate Contaminant

10. Preparation of Flushing Apparatus

Average Result,

10.1 Fig. 2 shows the recommended configuration of the 0.0 0.1 0.2 0.3 0.5 0.7 1.0 1.5 2.0

mg/L

flushing apparatus. Alternative apparatus may be used, pro-

Repeatability 0.07 0.09 0.11 0.12 0.16 0.19 0.25 0.33 0.42

Reproducibility 0.18 0.22 0.27 0.31 0.40 0.49 0.62 0.84 1.07

vided that it achieves the same end.

10.1.1 Wash the petri dishes and supports with warm water

containing detergent. Then rinse with warm water and finally

test (see Note 1), then W = W and the corrected mass of contaminant in

with distilled water.

1 3

12.3 becomes W − W .

2 4

10.1.2 Rinse thoroughly with filtered isopropyl alcohol.

10.1.3 Rinse thoroughly with filtered flushing fluid. 12.4 Reporttheresulttothenearest0.01mg/L,andalsothe

10.1.4 Drain for a few seconds, and then air or oven dry. sample volume used in the test.

10.2 Ensure that all glass and plastic tubing attached to the 7

13. Precision and Bias

solvent filtering dispenser is clean by flushing thoroughly with

13.1 The precision of this test method is not known to have

filtered flushing fluid.

beenobtainedinaccordancewithcurrentlyacceptedguidelines

11. Flushing and Weighing Procedure

in Committee D02 RR:D02-1007.

11.1 Upon receipt of the field monitor in the laboratory,

13.2 These precision data have been obtained by statistical

assemble the apparatus shown in Fig. 2 with the field monitor

examination of test results using 5L samples and were first

in place on the stopper of the vacuum flask. published in 1966.

NOTE 4—Take care to ensure that monitors are tightly closed and 13.3 Repeatability—The difference between successive re-

preferably clamped. Spring paper clips have been found suitable for this

sults obtained by the same operator with the same apparatus

purpose.

under constant operating conditions on identical test material

11.2 Place the tip of the delivery spout of the solvent would, in the long run, in the normal and correct operation of

filtering dispenser in direct contact with the monitor inlet hole.

the test method, exceed the following values in only one case

Introduce filtered flushing fluid. in twenty:

Range Repeatability

11.3 Apply vacuum to the flask and allow approximately

0.0 mg ⁄L to 2.0 mg/L 0.175x + 0.070

250 mLof filtered flushing fluid to pass from the flushing fluid

where x is the average value of two results.

dispenser through the monitor and into the vacuum flask.

13.4 Reproducibility—The difference between two single

11.4 Removetheflushingfluiddispenserandslowlyrelease

and independent results obtained by different operators work-

the vacuum.

ing in different laboratories on identical test material would, in

11.5 Remove the monitor from the stopper of the vacuum

the long run, exceed the following values in only one case in

flask and carefully dismantle it in an upright position.

twenty:

11.6 Carefullyremovethetestandcontrolmembranefilters,

Range Reproducibility

0.0 mg ⁄L to 2.0 mg/L 0.444x + 0.178

and place side by side on clean glass supports in a clean,

covered petri dish.

where x is the average value of two results.

NOTE 5—The test and control membrane filters can be removed from 13.5 Typical values are given in Table 1.

themonitorbypushingupwardsagainstthesupportpadthroughtheoutlet

NOTE 7—Reproducibility values were determined through cooperative

orifice with a thin dowel.

testingbydifferentoperatorsusingseparateapparatusworkingatthesame

11.7 Dry and reweigh the membrane filters as described in

location using identical test material. This procedure was adopted as it is

8.1.2 – 8.1.5, taking care not to disturb the contaminant on the highly improbable, if not impossible, to ensure the obtaining of “identical

test material” when testing at different locations.

surface of the test membrane filter.

13.6 Bias—The procedure given for the determination of

12. Calculation and Report

particulate contaminant in aviation turbine fuels has no bias

12.1 Subtract the initial mass of the test membrane filter, since this property can only be defined in terms of this test

W , from the final mass, W . method.

1 2

12.2 Subtracttheinitialmassofthecontrolmembranefilter,

14. Keywords

W , from the final mass, W .

3 4

14.1 aviation fuel; color rating; field monitor; gravimetric

12.3 Divide the correct mass of contaminant

contaminant; membrane color; membrane filter; particulate

(W − W)−(W − W ) by the volume of sample filtered and

2 1 4 3

report the result as total contaminant, expressed in milligrams

Supporting data have been filed atASTM International Headquarters and may

per litre.

beobtainedbyrequestingResearchReportRR:D02-1197.ContactASTMCustomer

NOTE 6—If matched-weight membrane filters have been used for the Service at service@astm.org.

D2276 − 22

ANNEXES

(Mandatory Information)

A1. PRECAUTIONARY STATEMENTS

A1.1 Isopropyl Alcohol A1.2.6 Avoid prolonged or repeated skin contact.

A1.1.1 Keep away from heat, sparks, and open flame.

A1.3 Aviation Turbine Fuel (Jet A or A-1, see Specification

D1655)

A1.1.2 Keep container closed.

A1.3.1 Keep away from heat, sparks, and open flames.

A1.1.3 Use with adequate ventilation.

A1.3.2 Keep container closed.

A1.1.4 Avoid prolonged breathing of vapor or spray mist.

A1.3.3 Use with adequate ventilation.

A1.1.5 Avoid contact with eyes and skin.

A1.3.4 Avoid breathing vapor or spray mist.

A1.1.6 Do not take internally.

A1.3.5 Avoid prolonged or repeated contact with skin.

A1.2 Petroleum Ether

A1.4 Aviation Turbine Fuel (Jet B, see Specification D6615)

A1.2.1 Keep away from heat, sparks, and open flame.

A1.4.1 Keep container closed.

A1.2.2 Keep container closed.

A1.4.2 Use with adequate ventilation.

A1.2.3 Use with adequate ventilation.

A1.4.3 Avoid build-up of vapors and eliminate all sources

of ignition, especially nonexplosion-proof electrical apparatus

A1.2.4 Avoid build-up of vapors and eliminate all sources

and heaters.

of ignition, especially nonexplosion-proof electrical apparatus

and heaters.

A1.4.4 Avoid breathing vapor or spray mist.

A1.2.5 Avoid prolonged breathing of vapor or spray mist. A1.4.5 Avoid prolonged or repeated contact with skin.

A2. SAMPLING AVIATION TURBINE FUEL FOR PARTICULATE CONTAMINATION

A2.1 Scope If a shut-off valve is desired, a stainless steel ball or plug-type

valve should be used.

A2.1.1 This test method covers taking samples of aviation

turbine fuels from fuel handling systems under pressure, A2.3.2 Field SamplingApparatus,asillustratedinFig.A2.1

through field monitors, for the determination of particulate

and consisting of the following components:

contaminant.

A2.3.2.1 Sampling Valve Connection, designed to meet the

followingrequirements:(1)Itshallbemountedinthesampling

A2.2 Summary of Test Method

point and must incorporate a self-sealing quick disconnect

A2.2.1 A3.785to5Lsampleistakenfromaflowinglineor valvetomatewithasuitableconnectionleadingtotheselector

pipe and passed under line pressure through a field monitor valve of the assembly. (2) It must be completely resistant to

containing a preweighed 0.8µm test membrane filter and a fuel and be leak proof up to the maximum working pressures

preweighed 0.8µm control

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2276 − 06 (Reapproved 2014) D2276 − 22

Designation: 216/97216/05 (2005)

Standard Test Method for

1,2

Particulate Contaminant in Aviation Fuel by Line Sampling

This standard is issued under the fixed designation D2276; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 This test method covers the determination of particulate contaminant in aviation turbine fuel using a field monitor.

1.2 There are two test methods described. The basic test method is used to evaluate the level of contamination gravimetrically.

The second test method, presented in Appendix X1, describes a color rating technique that is used for rapid qualitative assessment

of changes in contamination level without the time delay required for the gravimetric determinations by stringent laboratory

procedures.

1.3 There are two Annexes and two Appendixes in this test method.

1.3.1 Annex A1 provides some precautionary information regarding the use of the required reagents.

1.3.2 Annex A2 describes a standard practice for obtaining a sample of the particulates present in a flowing stream of aviation

turbine fuel.

1.3.3 Appendix X1 describes a test method for rating the particulate level in an aviation turbine fuel on the basis of the color of

a filter membrane after sampling the fuel in the field.

1.3.4 Appendix X2 provides some safety precautions to avoid static discharge resulting from the accumulation of electrical

charges in the fuel and on the equipment while following the procedures.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

This test method is under the jurisdiction of ASTM International Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility

of ASTM Subcommittee D02.J0.05 on Fuel Cleanliness. The technically equivalent standard as referenced is under the jurisdiction of the Energy Institute Subcommittee

SC-B-11.

This test method has been approved by the sponsoring committees and accepted by the Cooperating Societies in accordance with established procedures.

Current edition approved June 1, 2014July 1, 2022. Published July 2014September 2022. Originally approved in 1964. Last previous edition approved in 20062014 as

D2276D2276 – 06 (2014).–06. DOI: 10.1520/D2276-06R14.10.1520/D2276-22.

This test method has been developed through the cooperative effort between ASTM and the Energy Institute, London. ASTM and IP standards were approved by ASTM

and EI technical committees as being technically equivalent but that does not imply both standards are identical.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2276 − 22

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D1535 Practice for Specifying Color by the Munsell System

D1655 Specification for Aviation Turbine Fuels

D2244 Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D4865 Guide for Generation and Dissipation of Static Electricity in Petroleum Fuel Systems

D5452 Test Method for Particulate Contamination in Aviation Fuels by Laboratory Filtration

D6615 Specification for Jet B Wide-Cut Aviation Turbine Fuel

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer to Terminology D4175.

3.2 Definitions:Definitions of Terms Specific to This Standard:

3.2.1 membrane color, n—a visual rating of particulate on a filter membrane against ASTM Color Standards.

3.2.2 membrane filter, n—a porous article of closely controlled pore size through which a liquid is passed to separate matter in

suspension.

3.2.2.1 Discussion—

RR:D02-1012 contains information on membrane filters that meet the requirements therein.

3.2.3 monitor, n—something that reminds or warns.

3.2.3.1 Discussion—

A plastic holder for a membrane filter held in a field sampling apparatus.

3.2.4 particulate, adj—of or relating to minute separate particles.

3.2.4.1 Discussion—

Solids generally composed of oxides, silicates, and fuel insoluble salts.

3.2.5 volatile fuels, n—relatively wide boiling range volatile distillate.

3.2.5.1 Discussion—

These are identified as Jet B in Specification D6615 or the military grade known as JP-4.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 volatile fuels, n—relatively wide boiling range volatile distillate.

3.2.1.1 Discussion—

These are identified as Jet B in Specification D6615 or the military grade known as JP-4.

4. Summary of Test Method

4.1 A known volume of fuel is filtered through a preweighed test membrane filter in a field monitor and the increase in membrane

filter mass determined after washing and drying. The change in mass of a control membrane filter located immediately below the

test membrane filter is also determined. The objective of using a control membrane is to assess whether the fuel itself influences

the weight of a membrane. The particulate contaminant is determined from the increase in mass of the test membrane filter relative

to the control membrane filter.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Supporting data (and a list of suppliers who have provided data indicating their membranes, field monitors, and field monitor castings) have been filed at ASTM

International Headquarters and may be obtained by requesting Research Report RR:D02-1012. Contact ASTM Customer Service at service@astm.org.

D2276 − 22

4.2 This test method employs a field monitor to filter a sample of fuel that is taken in the field by the sampling procedure detailed

in Annex A2.

4.3 For situations where it is not possible to take a field monitor sample, procedures are given in Test Method D5452 for the

determination of particulate contaminant in a fuel sample by laboratory filtration.

4.4 Appendix X1 describes a method for color-rating used filter membranes.

5. Significance and Use

5.1 This test method provides a gravimetric measurement of the particulate matter present in a sample of aviation turbine fuel by

line sampling. The objective is to minimize these contaminants to avoid filter plugging and other operational problems. Although

tolerable levels of particulate contaminants have not yet been established for all points in fuel distribution systems, the total

contaminant measurement is normally of most interest. The Appendix X1 color rating method is useful for fuel system monitoring

purposes. No quantitative relationship exists between gravimetric and color rating test results.

6. Apparatus

6.1 Analytical Balance, single- or double-pan, the precision standard deviation of which must be 0.07 mg or better.

6.2 Oven, of the static type (without fan-assisted air circulation), controllable to 9090 °C 6 5°C.5 °C.

6.3 Petri Dishes, approximately 125 mm in diameter with removable glass supports for membrane filters.

6.4 Forceps, flat-bladed with unserrated, non-pointed tips.

6.5 Vacuum System.

4,5

6.6 Test Membrane Filters, plain, 37-mm37 mm diameter, nominal pore size 0.8 μm (see Note 1).

4,5

6.7 Control Membrane Filters, 37-mm37 mm diameter, nominal pore size 0.8 μm. (Gridded control membrane filters may be

used for purpose of identification.)

NOTE 1—Matched weight membrane filters, 37-mm37 mm diameter, nominal pore size 0.8 μm, may be used as test and control membrane filters if so

desired. Use of matched-weight membrane filters precludes the necessity for carrying out subsequently the procedures detailed in Section 8.

6.8 Dispenser for Flushing Fluid, 0.45-μm0.45 μm membrane filters to be provided in the delivery line (see Fig. 1). Alternatively,

flushing fluid that has been pre-filtered through a 0.45 μm membrane before delivery to the dispenser flask is acceptable.

6.9 Field Monitors, complete with protective plugs and 34-mm34 mm support pads.

6.10 Air Ionizer, for the balance case (see Note 2 and Note 3).

NOTE 2—When using a solid-pan balance, the air ionizer may be omitted provided that, when weighing a membrane filter, it is placed on the pan so that

no part protrudes over the edge of the pan.

NOTE 3—Air ionizers should be replaced within 1 year of manufacture.

6.11 Multimeter/VOM, used for determining whether electrical continuity is 10 Ω or less between 2 points.

All available membrane filters are not suitable for this application. Apparatus considered for this application shall be checked by the user for suitability in accordance

with the requirements of RR:D02-1012, 1994 revision.

D2276 − 22

FIG. 1 Apparatus for Filtering and Dispensing Flushing Fluid

6.12 Field Monitor Flushing Apparatus, of the type shown in Fig. 2. It consists of a receiving flask large enough to contain the

flushing fluid and shall be equipped with a side arm to connect to the vacuum system. Reagent resistant tubing shall be arranged

to allow passage of a grounding wire. An assembly of reagent grade resistant tubing and bung fitted with a glass tube shall be

assembled as shown in Fig. 2 to attach to a field monitor.

6.13 Ground/Bond Wire, Nos. 10 through 19, (0.912(0.912 mm to 2.59 mm) bare stranded flexible stainless steel or copper

installed in the flask and grounded as shown in Fig. 2.

7. Reagents

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

7.2 Purity of Water—Unless otherwise indicated references to water shall be understood to mean reagent water as defined by Type

III of Specification D1193.

7.3 Isopropyl Alcohol, reagent grade. (Warning—Flammable. See A1.1.)

7.4 Liquid Detergent, water-soluble.

7.5 Flushing Fluids:

7.5.1 Petroleum Spirit (also known as petroleum ether or IP Petroleum Spirit 40/60) (Warning—Extremely flammable. Harmful

if inhaled. Vapors are easily ignited by electrostatic discharges, causing flash fire. See A1.2.), having boiling range from 3535 °C

to 60°C.60 °C.

Reagent Chemicals, American Chemical Society Specifications,ACS Reagent Chemicals, Specifications and Procedures for Reagents and Standard-Grade Reference

Materials, American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by the American Chemical Society, see Analar Standards for

Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC),

Rockville, MD.

D2276 − 22

FIG. 2 Field Monitor Flushing Apparatus

8. Preparation of Test and Control Membrane Filters and Field Monitors Prior to Sampling

8.1 Two 37-mm37 mm membrane filters of nominal pore size 0.8 μm 0.8 μm are required: a test and a control membrane filter.

Matched-weight membrane filters may be used if so desired (see Note 1). If matched-weight membrane filters are used, it is

unnecessary to carry out the procedures detailed in this section because they have been carried out previously by the membrane

filter supplier. The two membrane filters used for each individual test should be identified by marking the petri dishes used as

containers. Glassware used in preparation of membrane filters shall be cleaned as described in Section 10.

8.1.1 Using forceps, place the test and control membrane filters side by side in a clean petri dish. To facilitate handling the

membrane filters should rest on clean glass support rods in the petri dish.

8.1.2 Place the petri dish with its lid slightly ajar, in an oven at 9090 °C 6 5°C5 °C and leave it for 30 min.

8.1.3 Remove the petri dish from the oven and place it near the balance. The petri dish cover should be ajar but still protecting

the membrane filters from contamination from the atmosphere. Allow 30 min for the membrane filters to come to equilibrium with

the ambient air temperature and humidity.

8.1.4 Remove the control membrane filter from the petri dish with forceps, handling by the edge only, and place it centrally on

the weighing pan. Weigh it and return it to the petri dish.

8.1.5 Repeat 8.1.4 for the test membrane filter. Record the membrane filter masses.

8.1.6 Take a clean field monitor, mark for identification, rinse with filtered flushing fluid, and insert a clean support pad.

8.1.7 Using clean forceps, place the weighed control membrane filter centrally on the support pad in the field monitor and place

the weighed test membrane filter on top of the control membrane filter. Assemble the two parts of the field monitor, ensuring that

the membrane filters are firmly clamped inside and the protective plugs are in position.

8.1.8 Record the monitor identification.

9. Sampling and Testing Procedure

9.1 When possible, 3.785 L (1 gal) to 5 L (1.321 gal) of fuel should be passed through the monitor during field sampling. The

sample volume actually employed shall be reported. (Warning—Jet A, combustible. Vapor harmful. See A1.3.) (Warning—Jet

B, extremely flammable. Harmful if inhaled. Vapors may cause flash fire. See A1.4.)

9.2 See Annex A2 for specific details of sampling practices that shall be followed.

D2276 − 22

10. Preparation of Flushing Apparatus

10.1 Fig. 2 shows the recommended configuration of the flushing apparatus. Alternative apparatus may be used, provided that it

achieves the same end.

10.1.1 Wash the petri dishes and supports with warm water containing detergent. Then rinse with warm water and finally with

distilled water.

10.1.2 Rinse thoroughly with filtered isopropyl alcohol.

10.1.3 Rinse thoroughly with filtered flushing fluid.

10.1.4 Drain for a few seconds, and then air or oven dry.

10.2 Ensure that all glass and plastic tubing attached to the solvent filtering dispenser is clean by flushing thoroughly with filtered

flushing fluid.

11. Flushing and Weighing Procedure

11.1 Upon receipt of the field monitor in the laboratory, assemble the apparatus shown in Fig. 2 with the field monitor in place

on the stopper of the vacuum flask.

NOTE 4—Take care to ensure that monitors are tightly closed and preferably clamped. Spring paper clips have been found suitable for this purpose.

11.2 Place the tip of the delivery spout of the solvent filtering dispenser in direct contact with the monitor inlet hole. Introduce

filtered flushing fluid.

11.3 Apply vacuum to the flask and allow approximately 250 mL of filtered flushing fluid to pass from the flushing fluid dispenser

through the monitor and into the vacuum flask.

11.4 Remove the flushing fluid dispenser and slowly release the vacuum.

11.5 Remove the monitor from the stopper of the vacuum flask and carefully dismantle it in an upright position.

11.6 Carefully remove the test and control membrane filters, and place side by side on clean glass supports in a clean, covered

petri dish.

NOTE 5—The test and control membrane filters can be removed from the monitor by pushing upwards against the support pad through the outlet orifice

with a thin dowel.

11.7 Dry and reweigh the membrane filters as described in 8.1.2 – 8.1.5, taking care not to disturb the contaminant on the surface

of the test membrane filter.

12. Calculation and Report

12.1 Subtract the initial mass of the test membrane filter, W , from the final mass, W .

1 2

12.2 Subtract the initial mass of the control membrane filter, W , from the final mass, W .

3 4

12.3 Divide the correct mass of contaminant (W − W ) − (W − W ) by the volume of sample filtered and report the result as total

2 1 4 3

contaminant, expressed in milligrams per litre.

NOTE 6—If matched-weight membrane filters have been used for the test (see Note 1), then W = W and the corrected mass of contaminant in 12.3

1 3

becomes W − W .

2 4

D2276 − 22

TABLE 1 Statistical Information for Particulate Contaminant

Average Result,

0.0 0.1 0.2 0.3 0.5 0.7 1.0 1.5 2.0

mg/L

Repeatability 0.07 0.09 0.11 0.12 0.16 0.19 0.25 0.33 0.42

Reproducibility 0.18 0.22 0.27 0.31 0.40 0.49 0.62 0.84 1.07

12.4 Report the result to the nearest 0.01 mg/L, and also the sample volume used in the test.

13. Precision and Bias

13.1 The precision of this test method is not known to have been obtained in accordance with currently accepted guidelines in

Committee D02 RR:D02-1007.

13.2 These precision data have been obtained by statistical examination of test results using 5-L5 L samples and were first

published in 1966.

13.3 Repeatability—The difference between successive results obtained by the same operator with the same apparatus under

constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test

method, exceed the following values in only one case in twenty:

Range Repeatability

0.0 to 2.0 mg/L 0.175x + 0.070

0.0 mg ⁄L to 2.0 mg/L 0.175x + 0.070

where x is the average value of two results.

13.4 Reproducibility—The difference between two single and independent results obtained by different operators working in

different laboratories on identical test material would, in the long run, exceed the following values in only one case in twenty:

Range Reproducibility

0.0 to 2.0 mg/L 0.444x + 0.178

0.0 mg ⁄L to 2.0 mg/L 0.444x + 0.178

where x is the average value of two results.

13.5 Typical values are given in Table 1.

NOTE 7—Reproducibility values were determined through cooperative testing by different operators using separate apparatus working at the same location

using identical test material. This procedure was adopted as it is highly improbable, if not impossible, to ensure the obtaining of “identical test material”

when testing at different locations.

13.6 Bias—The procedure given for the determination of particulate contaminant in aviation turbine fuels has no bias since this

property can only be defined in terms of this test method.

14. Keywords

14.1 aviation fuel; color rating; field monitor; gravimetric contaminant; membrane color; membrane filter; particulate

Supporting data have been filed at ASTM International Headquarters and may be obtained by requesting Research Report RR:D02-1197. Contact ASTM Customer

Service at service@astm.org.

D2276 − 22

ANNEXES

(Mandatory Information)

A1. PRECAUTIONARY STATEMENTS

A1.1 Isopropyl Alcohol

A1.1.1 Keep away from heat, sparks, and open flame.

A1.1.2 Keep container closed.

A1.1.3 Use with adequate ventilation.

A1.1.4 Avoid prolonged breathing of vapor or spray mist.

A1.1.5 Avoid contact with eyes and skin.

A1.1.6 Do not take internally.

A1.2 Petroleum Ether

A1.2.1 Keep away from heat, sparks, and open flame.

A1.2.2 Keep container closed.

A1.2.3 Use with adequate ventilation.

A1.2.4 Avoid build-up of vapors and eliminate all sources of ignition, especially nonexplosion-proof electrical apparatus and

heaters.

A1.2.5 Avoid prolonged breathing of vapor or spray mist.

A1.2.6 Avoid prolonged or repeated skin contact.

D2276 − 22

A1.3 Aviation Turbine Fuel (Jet A or A-1, see Specification D1655)

A1.3.1 Keep away from heat, sparks, and open flames.

A1.3.2 Keep container closed.

A1.3.3 Use with adequate ventilation.

A1.3.4 Avoid breathing vapor or spray mist.

A1.3.5 Avoid prolonged or repeated contact with skin.

A1.4 Aviation Turbine Fuel (Jet B, see Specification D6615)

A1.4.1 Keep container closed.

A1.4.2 Use with adequate ventilation.

A1.4.3 Avoid build-up of vapors and eliminate all sources of ignition, especially nonexplosion-proof electrical apparatus and

heaters.

A1.4.4 Avoid breathing vapor or spray mist.

A1.4.5 Avoid prolonged or repeated contact with skin.

A2. SAMPLING AVIATION TURBINE FUEL FOR PARTICULATE CONTAMINATION

A2.1 Scope

A2.1.1 This test method covers taking samples of aviation turbine fuels from fuel handling systems under pressure, through field

monitors, for the determination of particulate contaminant.

A2.2 Summary of Test Method

A2.2.1 A 3.785 to 5-L5 L sample is taken from a flowing line or pipe and passed under line pressure through a field monitor

D2276 − 22

containing a preweighed 0.8-μm0.8 μm test membrane filter and a preweighed 0.8-μm0.8 μm control membrane filter. After

filtration the field monitor is returned to a laboratory for analysis.

NOTE A2.1—Examine the monitor carefully to ensure that it is located correctly in its holder (that is, not reversed). The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...