Petroleum and Energy Technologies Standards Summary – May 2025 Monthly Overview (Part 1)

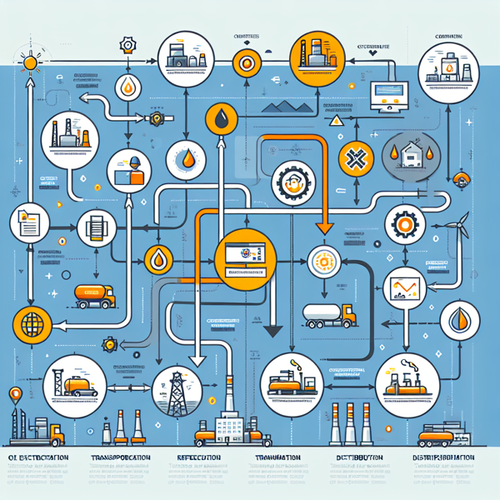

Looking back at May 2025, the Petroleum and Energy Technologies sector saw the release of five influential standards shaping vital aspects of fuel quality, risk management, operational safety, and sustainability. Each standard responded to a persistent industry need: more precise measurement, improved safety frameworks, greener fuels, and better lifecycle management of critical resources. For professionals across petroleum, energy, and fuel-related industries, reviewing these standards retrospectively not only helps close gaps in compliance, but also highlights strategic opportunities for process improvements and futureproofing. This overview delivers concise, contextual insights for each publication—essential reading for those wanting to stay ahead in a rapidly evolving landscape.

Monthly Overview: May 2025

May 2025 proved to be an active month for Petroleum and Energy Technologies standardization. Five standards spanning coal and coke analysis, LNG facility risk management, alternative fuel quality, biofuel durability, and turbine lubricant lifecycle were published. Notably, the cohort reflects both foundational maintenance of traditional infrastructures (such as coal testing and turbine oil management), and the sector’s pivot into new risk management and fuel paradigms—especially with guidance on LNG installation safety and advanced biofuel characterization.

This balance of publication subjects indicates an industry at a crossroads—retaining rigour in legacy practices while investing in next-generation fuels and safety protocols. In comparison to previous months, May 2025 stands out for its focus on operational resilience and bridging classic and emerging technologies.

Standards Published This Month

ISO 609:2025 – Coal and Coke – Determination of Carbon and Hydrogen – High Temperature Combustion Method

Coal and coke – Determination of carbon and hydrogen – High temperature combustion method

The third edition of ISO 609 addresses one of the most fundamental needs in coal chemistry: accurately determining the total carbon and hydrogen content of coal and coke using a high temperature combustion method. The standard details a protocol where samples are combusted in oxygen at 1350°C. Resultant gases—water (from hydrogen) and carbon dioxide (from carbon)—are collected and analyzed gravimetrically, ensuring precise quantification essential for both fuel appraisal and emissions management.

Updates in the 2025 edition include revised reference materials, an expanded definitions section, modified apparatus figures, and refined procedural steps—improving clarity and repeatability of results. Professionals in coal mining, coke production, utility plants, and testing laboratories will find this method vital for quality control and regulatory reporting across the globe.

This standard fits squarely within frameworks like ISO 11722 (coal sampling) or ISO 18283 (manual methods), updating the ecosystem of solid fuel characterization. Its focus on methodical, accurate analysis underpins cleaner combustion and fair trade in coal commodities.

Key highlights:

- Specifies high-precision method for measuring total carbon and hydrogen in coal/coke

- Updates apparatus instructions and figures for improved accuracy

- Ensures industry compliance for emissions, fuel valuation, and sampling protocols

Access the full standard:View ISO 609:2025 on iTeh Standards

CEN ISO/TS 16901:2025 – Guidance on Performing Risk Assessment in the Design of Onshore LNG Installations Including the Ship/Shore Interface

Guidance on performing risk assessment in the design of onshore LNG installations including the ship/shore interface (ISO/TS 16901:2022)

Risk management in liquefied natural gas (LNG) handling has become imperative as infrastructure scales, and CEN ISO/TS 16901:2025 answers this need with a harmonized, risk-based framework. The technical specification is designed for planners, designers, and operators of LNG facilities—encompassing both export/import terminals and supporting installations (such as satellite and peak shaving plants).

The document lays out comprehensive methodologies for identifying, assessing, and controlling major safety hazards, especially in the critical ship/shore interface—a known flashpoint for operational incidents. Covering both qualitative (HAZID, FMEA, bow-tie) and quantitative (frequency and consequence) analysis, the guidance empowers stakeholders to implement robust, scenario-driven safety cases, aligning with broader standards like IEC 31010 and ISO 17776. Navigation risks and direct LNG tanker risks are excluded, focusing discussions on terminal safety and hazardous material handling.

While it does not set strict risk acceptance thresholds, CEN ISO/TS 16901:2025 references industry benchmarks for tolerable risk and provides a structured path for integrating safety into LNG facility lifecycle planning.

Key highlights:

- Applies risk assessment processes specifically to onshore LNG facilities and ship/shore links

- Details a wide suite of qualitative and quantitative safety methods

- Offers practical guidance for integration with regulatory and industry best practices

Access the full standard:View CEN ISO/TS 16901:2025 on iTeh Standards

EN 15751:2025 – Automotive Fuels – Fatty Acid Methyl Ester (FAME) Fuel and Blends with Diesel Fuel – Determination of Oxidation Stability

Automotive fuels – Fatty acid methyl ester (FAME) fuel and blends with diesel fuel – Determination of oxidation stability by accelerated oxidation method at 110 °C

EN 15751:2025 is a cornerstone for professionals working with diesel alternatives and biofuel blends. The standard details a laboratory method to determine the oxidation stability of FAME (biodiesel) fuels—and blends with at least 2% FAME—by measuring the induction period at 110°C. This measurement is pivotal as fuel stability impacts engine longevity, emissions, and viability over storage and distribution.

Improvements in the latest revision aim to clarify testing procedures and ensure compatibility with diverse blend matrices, including paraffinic diesel fuels (though with caveats on precision). The test supports compliance with regulatory limits on oxidation stability and facilitates fair market trading by specifying clear, reproducible protocols. Fuel suppliers, vehicle OEMs, and compliance laboratories are direct beneficiaries.

Within the broader regulatory environment, EN 15751 complements EN 14112 and EN 16568, sitting alongside standards developed for other biofuel and diesel compositions.

Key highlights:

- Delivers a standardized, reproducible method for oxidation stability of FAME and blends

- Aids compliance with diesel/biofuel product standards and market requirements

- Supports sustainability and lower-emission fuel use by ensuring product integrity

Access the full standard:View EN 15751:2025 on iTeh Standards

EN ISO 17831-2:2025 – Solid Biofuels – Determination of Mechanical Durability of Pellets and Briquettes – Part 2: Briquettes

Solid biofuels – Determination of mechanical durability of pellets and briquettes – Part 2: Briquettes (ISO 17831-2:2025)

As biofuels gain traction in the energy mix, physical durability becomes critical for ensuring fuel quality from plant to end user. EN ISO 17831-2:2025 specifies a method for determining the mechanical durability of biofuel briquettes, focusing on their resistance to breakage and abrasion during handling and transport.

By offering a clear, reproducible tumbling and sieving procedure, the standard supports manufacturers, traders, and large-scale users in qualifying products per market and regulatory demands. Improved mechanical durability translates to less material loss, lower dust risks, and higher efficiency in storage, logistics, and combustion.

This second part builds on the series’ scope to cover both pellets and briquettes, underpinning a more robust, sustainable solid biofuel market.

Key highlights:

- Defines a standardized testing process for durability of compressed biofuel briquettes

- Supports supply chain efficiency and reduces waste through quality assurance

- Aligns with sustainability criteria for renewable energy products

Access the full standard:View EN ISO 17831-2:2025 on iTeh Standards

ISO 11366:2025 – Petroleum and Related Products – In-servicing of Steam, Gas and Combined Cycle Turbines Lubricating Oils – Guidance and Requirements

Petroleum and related products – In-servicing of steam, gas and combined cycle turbines lubricating oils – Guidance and requirements

ISO 11366 sets out comprehensive guidance and requirements for keeping turbine lubricating oils and control fluids in optimal condition throughout their operational lifecycle. Covering oils in steam, gas, and combined cycle turbines, the standard addresses maintenance, testing protocols, common modes of degradation (like oxidation, sludge, and water contamination), and corrective actions for prolonging lubricant performance.

Applicable primarily to mineral oils specified under ISO 6743-5 and ISO 8068 (excluding select phosphate esters), this guidance is invaluable to power plant operators, maintenance teams, and oil suppliers seeking to maximize service life, reduce failures, and stay aligned with best practices. Expanded from previous iterations, the 2025 edition folds in new definitions, additional deterioration tests (including membrane patch colorimetry and wear metals analysis), and explicit procedures for extending oil service.

In a regulatory context, this standard anchors reliability-focused programs and supports the industry’s increasing demand for plant availability and risk minimization.

Key highlights:

- Establishes condition monitoring and corrective frameworks for turbine lubricating oils

- Expands recommended test suites for in-service oils, supporting longer plant lifecycles

- Offers actionable procedures for sampling, interpretation, and oil life extension

Access the full standard:View ISO 11366:2025 on iTeh Standards

Common Themes and Industry Trends

Reviewing the standards published in May 2025 reveals several unifying trends across Petroleum and Energy Technologies:

- Precision and Repeatability: Whether in coal analysis or fuel stability, methodological improvements underscore a drive for highly reproducible—and defensible—lab results, reflecting increasing scrutiny in emissions and trade verification.

- Evolving Risk Management: LNG facility operators now have more robust frameworks for proactive hazard identification, underlining the sector’s commitment to safety in a period of infrastructure growth.

- Sustainability Shift: The presence of both FAME/diesel and biofuel briquette durability standards demonstrates the sector’s commitment to integrating renewable and low-carbon fuels, with quality assurance at every step.

- Operational Resilience: Broadening the scope of standards like ISO 11366 signals an emphasis on lifecycle asset management, minimizing downtime and maximizing efficiency in both mature and emerging energy systems.

- System Integration: Most standards encourage alignment with existing frameworks or reference companion documents, promoting interoperability, easier audits, and streamlined compliance programs.

The variety of subjects covered this month highlights a sector balancing foundational reliability with new fuel types and safety demands. Increased standardization around alternative fuels and risk management tools point to accelerating diversification and modernization across the industry value chain.

Compliance and Implementation Considerations

For organizations touched by these May 2025 standards, proactive engagement is key. Professionals should:

- Review Applicability: Assess which standards impact your products, processes, or services. For instance, fuel suppliers handling FAME blends or solid biofuels must update testing protocols per the latest EN 15751 and EN ISO 17831-2.

- Update Testing and Maintenance Routines: Laboratories and QA teams should recalibrate apparatus, retrain staff, and revise reporting standards—especially with updated procedures in ISO 609 and ISO 11366.

- Integrate Risk Management: LNG facility stakeholders must ensure that the CEN ISO/TS 16901 risk assessment approach is reflected in both new designs and ongoing operations. This may involve cross-functional workshops and scenario analysis.

- Align with Broader Frameworks: Use references and linked standards to ensure compliance across product lines and operational boundaries. For example, aligning oil sampling under ISO 11366 with procurement based on ISO 8068.

- Set Internal Timelines: Although most standards do not prescribe mandatory implementation dates, sector best practices dictate rapid review and adaptation—ideally well in advance of regulatory audits or contractual deadlines.

Resources such as iTeh Standards (https://standards.iteh.ai) provide comprehensive access, updates, and supporting materials for effective, up-to-date compliance.

Conclusion: Key Takeaways from May 2025

The standards published in May 2025 demonstrate an industry attentive to operational excellence, safety, and environmental stewardship. Key takeaways include:

- A renewed focus on quality control, both in legacy fuel streams (coal, coke) and new-generation biofuels

- Increased sophistication in managing operational risks, especially in LNG infrastructure

- Comprehensive, lifecycle-oriented frameworks for maintaining critical assets like turbines

- Integration of sustainability metrics across product and process standards

For professionals in Petroleum and Energy Technologies, staying abreast of these standards is an indispensable aspect of risk mitigation, competitive differentiation, and demonstrating commitment to responsible operations. To truly benefit, organizations must invest in review, training, and integration—transforming regulatory increments into operational advantages.

Explore all referenced standards and more at iTeh Standards

Categories

- Latest News

- New Arrivals

- Generalities

- Services and Management

- Natural Sciences

- Health Care

- Environment

- Metrology and Measurement

- Testing

- Mechanical Systems

- Fluid Systems

- Manufacturing

- Energy and Heat

- Electrical Engineering

- Electronics

- Telecommunications

- Information Technology

- Image Technology

- Precision Mechanics

- Road Vehicles

- Railway Engineering

- Shipbuilding

- Aircraft and Space

- Materials Handling

- Packaging

- Textile and Leather

- Clothing

- Agriculture

- Food technology

- Chemical Technology

- Mining and Minerals

- Petroleum

- Metallurgy

- Wood technology

- Glass and Ceramics

- Rubber and Plastics

- Paper Technology

- Paint Industries

- Construction

- Civil Engineering

- Military Engineering

- Entertainment